User and Maintenance Manual

Failsafe hydraulic brake ID 2000N

Model ID 2000N-116

Date: 2014/06/27

Revision: 1.1

www.coremo.it

Page

22

of

25

5.

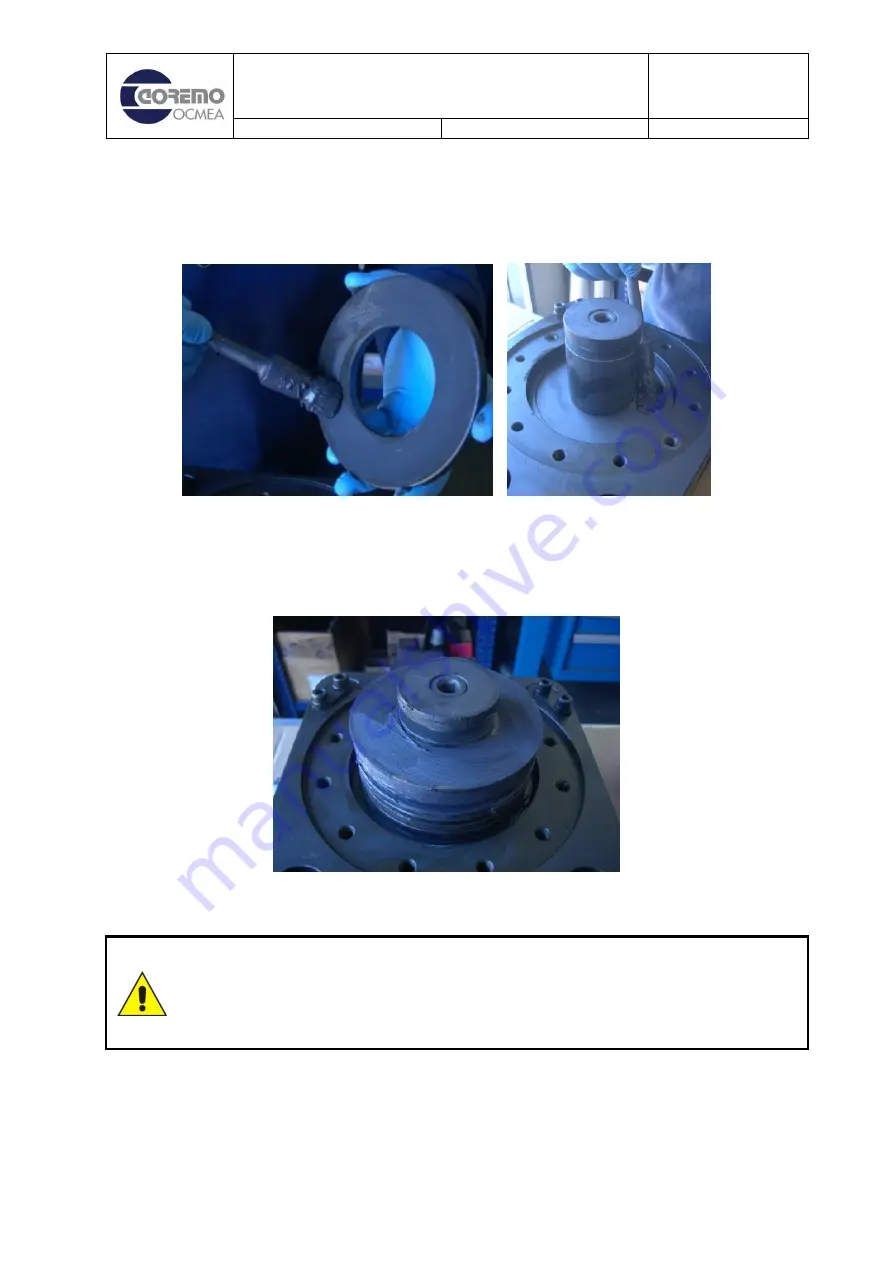

Lubricate the cup springs (Photo 39) and the part of the thruster in which they are housed

with copper paste MOLYguard COMPOUND RA/40 (or similar) (Photo 40), before

proceeding with reassembly.

Photo 39

Photo 40

6.

Insert in the thruster (D71243) the following parts in the following order: 1 shim C62295, 1

shim C62256, 6 cup springs C62410, 1 shim C62256 (Photo 41).

Photo 41

Position the cup springs correctly so that they do not affect the good operation of the

brake (Figure 3). Incorrect assembly will result in a tangential force different to what is

stated in this manual; the braking torque provided by the safety component will

consequently be different to what is desired and to the detriment of safety aspects.

7.

Put back the cover (D71242) on the brake body (E80834) using the screws (C61421)

complete with washers (C61321) (Photo 42). Tighten the M10 class 12.9 screws (C61452) in

a diagonal sequence with tightening torque 79 Nm (Photo 43).