10

P/N: 192090087 REV. AA

October 2021

MAINTENANCE (CONTINUED)

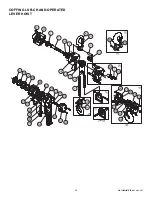

OPTIONAL LOAD LIMITER

The LSB-C lever hoist has an optional load limiter, a device

that is designed and calibrated to prevent excessive overloads.

Excessive overload is indicated by lever movement without the

corresponding movement of the lower hook block or load when

the unit is operated in the “UP” direction. If overload exists,

immediately switch the lever to the “DOWN” position and operate

the lever to remove the excess load from the units.

Reducing the load to the rated capacity or less will automatically

restore the normal operation of the unit. To convert a standard

LSB-C lever hoist to a unit with the overload protection, replace

reference no. 80 (See Figure 9).

Refer to chart below for the appropriate load limiter for your

capacity hoists.

Figure 9: Overload Protection Device

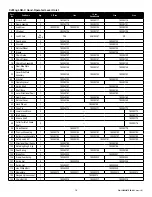

Hoist Capacity

(Tons)

Part

No.

Ket Part Number

3/4

80

IRB5080U

1

80

JRB5080U

1-1/2

80

KRB5080CU

3

80

NRB5080U

6

80

QRB5080U

Table 4: Overload Protection Kits

The load limiter may require adjustment when it slips at or below

the rated load. Refer to chart below for the correct torque setting

for the load limiter. Only adjust the load limiter by item 110 in

Figure 9. If the load limiter cannot be corrected by adjusting the

torque setting or if any of the parts are damaged, replace the

load limiter. A special tool is required to adjust Item 110 properly

(Contact factory).

Hoist Capacity

(Tons)

Torque Range (ft-lbs)

LSB1500B

28-32

LSB3000B

59-66

LSB6000B

77-85

LSB1500B

77-85

Table 5: Torque Range

NOTE: Excessive torque will damage the load limiter and could

cause equipment damage or personal injury.

CAUTION

The load limiter is subject to overheating and wear when

excessively actuated. For this reason, once overloading is

detected, remove the excess load, restore normal operation, and

watch for any continued undue operation.

The load limiter is designed to operate dry, without lubrication. To

ensure proper operation, DO NOT apply lubricant to the friction

surfaces or to adjacent parts of the load limiter.

TESTING

Test the load limiter during periodic inspections. To perform

this test, attach the lower hook to a load at maximum 200% of

rated capacity and operate the unit in the “UP” direction. When

attempting to lift the load, the lever should slip. After this test,

move the trigger to the “DOWN” position and operate the unit to

remove the tension from the units. Once tension releases, the

unit should return to normal operation. If the load does not slip at

200% of capacity, replace the load limiter.

RECOMMENDED SPARE PARTS

Ratchet Disc Assembly

Latch Kit

Upper & Lower Hook Assembly

!

WARNING

Alterations or modifications of equipment and use of any parts

other than Coffing LSB-C lever hoist repair parts can lead to

dangerous operation and injury.

TO AVOID INJURY:

Do not alter or modify equipment. Only use replacement parts

provided by Coffing LSB-C.

PREVENTATIVE MAINTENANCE

In addition to conducting inspections, establish a preventative

maintenance program to prolong the useful life of the hoist and

maintain its dependability and continued safe use.

The program should include periodic inspections focusing on

lubricating various components using the recommended lubricants

(See Table 7).

TESTING

Prior to initial use, the user should test all repaired or used hoists

that have not been operated for the previous 12 months, checking

for proper operation.

1.

Test the unit first in the unloaded state.

2.

Then test the unit with a light load of 100 lbs (45 kg) times the

number of load-supporting parts of load chain to be sure it

operates properly and the brake holds the load when the lever

is released.

3.

Then test the unit with a load of 125% of rated capacity.

4.

In addition, test hoists in which load-sustaining parts have

been replaced. Test them at 125% of rated capacity by or

under the direction of a designated person and prepare a

written report for record purposes.

NOTE: For additional information on inspection and testing, refer

to ASME B30.21, “Manually Operated Lever Hoists” (obtainable

from asme.org).