9

P/N: 192090087 REV. AA

October 2021

MAINTENANCE (CONTINUED)

Slack the portion of the chain that normally passes over the lift-

wheel. Examine the interlink area for the point of maximum wear

(polishing). Measure and record the stock diameter at this point

of the link. Then measure stock diameter in the same area on the

link that does not pass over the lift-wheel (use the link adjacent to

the chain stop for this purpose). If the measurements do not follow

the measurements in Figure 8, replace the chain.

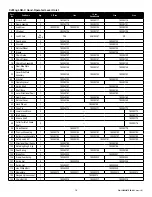

Hoist Capacity

(Tons)

Diameter

(mm)

Standard Size

(in.)

Limit

(in.)

3/4 and 1

5.6

6.732

6.866

1-1/2

7.1

8.346

8.511

3

9

10.709

10.923

6

9

10.709

10.923

Table 3: Chain Measurements

Vernier Caliper

One

Pitch

Measure 10 pitches

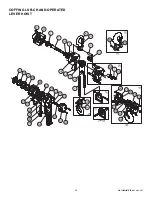

Figure 8: Chain Inspection

Check the chain for stretch using a vernier caliper as shown in

Figure 8. Select an unused, unstretched section of chain (usually

at the loose end) and measure and record the length over 11

chain links (pitches). Measure and record the same length on a

worn section of chain.

If the amount of stretch and wear exceeds 0.145 in. (3.7 mm),

replace the chain.

Use only a “knife-edge” caliper to eliminate the possibility of a

false reading by not measuring the full pitch length.

!

WARNING

Using other than a Coffing-supplied load chain may cause the

chain to jam in the hoist and/or allow the chain to break and the

load to drop.

TO AVOID INJURY

Due to size requirements and physical properties, use only

Coffing Supplied LSB-C supplied load chain in the LSB-C lever

hoist.

Note that a worn chain can indicate worn hoist components.

Examine the hoist’s frame, stripper, and lift-wheel for wear and

replace it as necessary when replacing worn chain.

Also, the load chain is specially heat treated and hardened and

should never be repaired.

Important:

Do not use a replaced chain for other purposes such

as lifting or pulling. The load chain may break suddenly without

any visual deformation. For this reason, cut replaced chain into

short lengths to prevent its use after disposal.

CHAIN LUBRICATION

A small amount of lubricant will greatly increase the life of the

load chain. Do not allow the chain to run dry. Keep it clean and

lubricate at regular intervals with SAE 20-30 machine oil or

equivalent lubricant. Normally, weekly lubrication and cleaning

is satisfactory, but under hot and dirty conditions, it may be

necessary to clean the chain at least once a day and lubricate it

several times between cleanings.

!

WARNING

Used motor oils contain known carcinogenic materials.

TO AVOID INJURY:

Never use used motor oils as a chain lubricant. Only use SAE

20-30 machine oil as a lubricant for the load chain.

When lubricating the chain, apply sufficient lubricant to obtain

natural run-off and full coverage, especially in the interlink area.

Hoist normally requires no additional lubrication except when it

has been disassembled for cleaning or repairs.

Important:

The brake is designed to operate dry. Do not use any

grease or lubricant on the braking surfaces.

When lubricating parts adjacent to the brake, do not use an

excessive amount of lubricant, which could seep onto the brake

surfaces.

!

WARNING

Using any grease or lubricant on the braking surfaces will

cause brake slippage and loss of load control, which may result

in injury and/or property damage.

TO AVOID INJURY:

Do not use any grease or lubricant on braking surfaces. The

brake is designed to operate dry.