6

P/N: 192090087 REV. AA

October 2021

OPERATION (CONTINUED)

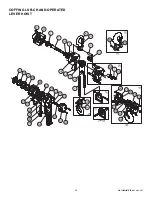

Figure 1: Lever Hoist

ATTACHING THE LOAD

Attach the lower hook to the load so that it is seated in the bowl

of the hook and is not bearing against the tip of the hook or latch.

Ensure that the latch is tight against the hook tip.

!

WARNING

Allowing the load to bear against the hook latch and/or hook tip

can result in loss of load.

TO AVOID INJURY:

Do not allow the load to bear against the hook latch and/or

hook tip. Apply load to hook bowl or saddle only.

Do not wrap the chain around the load and hook onto itself as a

choker chain sling and never bring the load in contact with the

hoist. Doing this will result in the loss of the swivel effect of the

hook, which could cause a twisted chain and a jammed lift-wheel.

Also, the chain may be damaged at the hook. Make sure the

upper and lower hooks are in a straight line and the frame is free

to swivel on the upper hook.

HOISTING (PULLING) AND LOWERING (RELEASING)

2:

3:

Free-wheeling

4:

Figure 2:

Lifting

Figure 3:

Lowering

Figure 4:

Free-Wheeling

When pulling or lifting, move the load only enough to slightly load

the unit, then check to be sure that the attachments to the hooks

and load are firmly seated. Continue movement only after you are

assured the load is free of all obstructions. Lift loads as slowly

as possible. Load swinging and abrupt shocks will impose on

the lever hoist excessive burdens that may more than double the

weight of the load.

Hoisting (Pulling)

See Figure 2. Set the selector lever to the “UP” position. Take

up the slacked load chain by turning the guide handle clockwise.

Next, manipulate the operating handle clockwise.

Lowering (Releasing)

See Figure 3. Set the selector lever to the “DOWN” position.

Manipulate the operating handle counterclockwise. When there

is no load on the lever hoist, the load chain can be slacked by

turning the guide handle counterclockwise.

The hoist has been designed for hand powered operation only.

Do not use an extension on the lever. Any pound-force greater

than the following pound-forces indicates an overload or incorrect

maintenance:

•

Pound-force over 67.5 for the 3/4-ton unit

•

Pound-force over 84 for the 1-ton unit

•

Pound-force over 96 for the 1-1/2-ton unit

•

Pound-force over 103 for the 3-ton unit

•

Pound-force over 116 for the 6-ton unit

!

WARNING

Power operation may cause structural damage or premature

wear that in turn may cause a part to break and allow the load

to fall.

TO AVOID INJURY:

Operate the Coffing LSB-C lever hoist using hand power only!

FREE-CHAINING

See Figure 4. In this mode of operation, pull the chain through the

hoist in either direction by hand for quick attachment to the load.

To engage the free-chaining feature, remove any load from the

hoist, move the directional lever to the (“N”) position, and pull the

load chain out in the desired direction.

Free-chaining will not be possible during the following conditions:

1.

When the lever hoist is under a load.

2.

When the guide handle is in contact with something and not

rotating freely.

3.

When the brake has locked from a large or abrupt shock load:

Turn the guide handle 45 degrees counterclockwise to unlock

the brake.