OPERATION

PRIMING THE PUMP

NOTE:

The pump is shipped

WITHOUT

oil. Before starting, pour

in oil provided in the pump through the oil nozzle. The

break-in oil should be changed after 8 hours of

operation. To reduce maintenance and repair problems,

use only premium compressor oil. SAE 10W-30 all

weather air compressor oil is recommended for

general use.

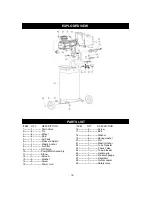

1. Check the oil level in the pump through the oil sight glass.

The pump oil level must be between A1 and A2. Do not

overfill or underfill. (See A)

2. Turn the pressure switch to the OFF position (See B)

3. Open the tank drain valve (See C). Turn counterclockwise.

4. Plug in the power cord

5. Turn the pressure switch to the ON position (See D). The

unit will start. Allow the unit to run for half an hour to break

in the internal parts. After half an hour, if the unit does not

operate properly, shut down immediately and contact

GreatNeck Service Center at 1-855-900-2653.

6. After half an hour, turn the pressure switch to the OFF

position.

7. Close the tank drain valve. Turn clockwise.

8. Turn the pressure switch to the ON position. The unit will

start and fill the tank to the cut-out pressure and stop.

NOTE:

The pressure switch will restart the motor automatically

as compressed air is used.

STARTUP

1. Before starting, check the oil sight glass to ensure that oil

level in the pump is at the required level.

2. Turn the pressure switch to the OFF position.

3. Close the tank drain valve.

4. Plug in the power cord.

5. Turn the pressure switch to the ON position.

6. Adjust the pressure regulator to the working pressure of

the tool.

When adjusting from a higher to a lower pressure, turn the

knob counterclockwise past the desired setting, then turn

clockwise to reach the desired pressure. DO NOT exceed

operating pressure of the tool or accessory being used.

SHUTDOWN

1. Turn the pressure switch to the OFF position.

2. Unplug the power cord.

3. Reduce pressure in the tank through the outlet hose. You

can also pull the relief valve ring and keep it open to relieve

pressure in the tank. (See E)

CAUTION

Escaping air and moisture can propel debris that

may cause eye injury. Wear safety goggles when opening

drain valve.

B

C

A

D

E

CLOSE

OPEN

- 7-

ON

OFF