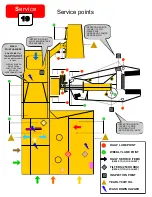

BELT AND TENSIONER

BELT

Check belt regularly for tension

and wear. Make adjustments as necessary.

TENSIONER

Check belt tension hourly

when new and daily during inspection.

S

ervice

21

CAGE MOUNTS

CAGE

Regularly check cage

frame for wear or cracks.

RUBBER MOUNTS

Replace

hanger mounts if cracked or

deformed.

BOLT & NUT

Make sure nuts

are not loose or that bolts are

not bent.

WASHER

Top and lower

washers may wear check regu-

larly.

TIGHTEN

Nuts and bolts after

initial use. Loose mounts will

cause excessive swinging of

the head.

BELT AND TENSIONER

BELT

Check belt regularly for tension

and wear. Make adjustments as necessary.

TENSIONER

Check belt tension hourly

when new and daily during inspection.

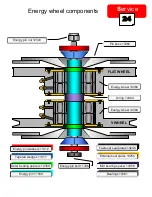

ENERGY WHEEL COMPONENTS

BEARINGS

Inspect bearings regularly for excessive play.

This may be a indication of failing bearings. Replace as neces-

sary.

Grease energy wheel bearings every other day of use with

2 pumps, more often if needed. Only use COE grease or war-

ranty is void.

WEIGHTS

Periodically check weight bolt torque. Loose

bolts can shear causing damage.

MAIN BOLT

Periodically check energy pin bolt torque. If

bolt becomes loose damage will occur.

SHAKER HEAD HOSES

HOSES

check hoses regularly for

wear or leaks. Tree limbs can also

fall and damage or break hoses. Re-

place or adjust as necessary.

Содержание R Series

Страница 1: ...OWNERS MANUAL COE S7 R SERIES SIDE MOUNT SHAKER VERSION 1 1 ...

Страница 2: ......

Страница 8: ...Operation 5 Cab OPERATORS CAB AREA DISPLAY JOYSTICK ...

Страница 30: ...Service 27 Component locations 40A 40A 40A 40A AC 60A RADIATOR 100A 200A AC RADIATOR ...

Страница 44: ...Circuits 41 S7R electrical circuit ...

Страница 45: ...Circuits 42 ...