C11G (Rev.8.2) User Manual

Revision: 01/27/2010 http://cnc4pc.com/TechDocs/C11GR8_2_User_Manual.pdf 5/21

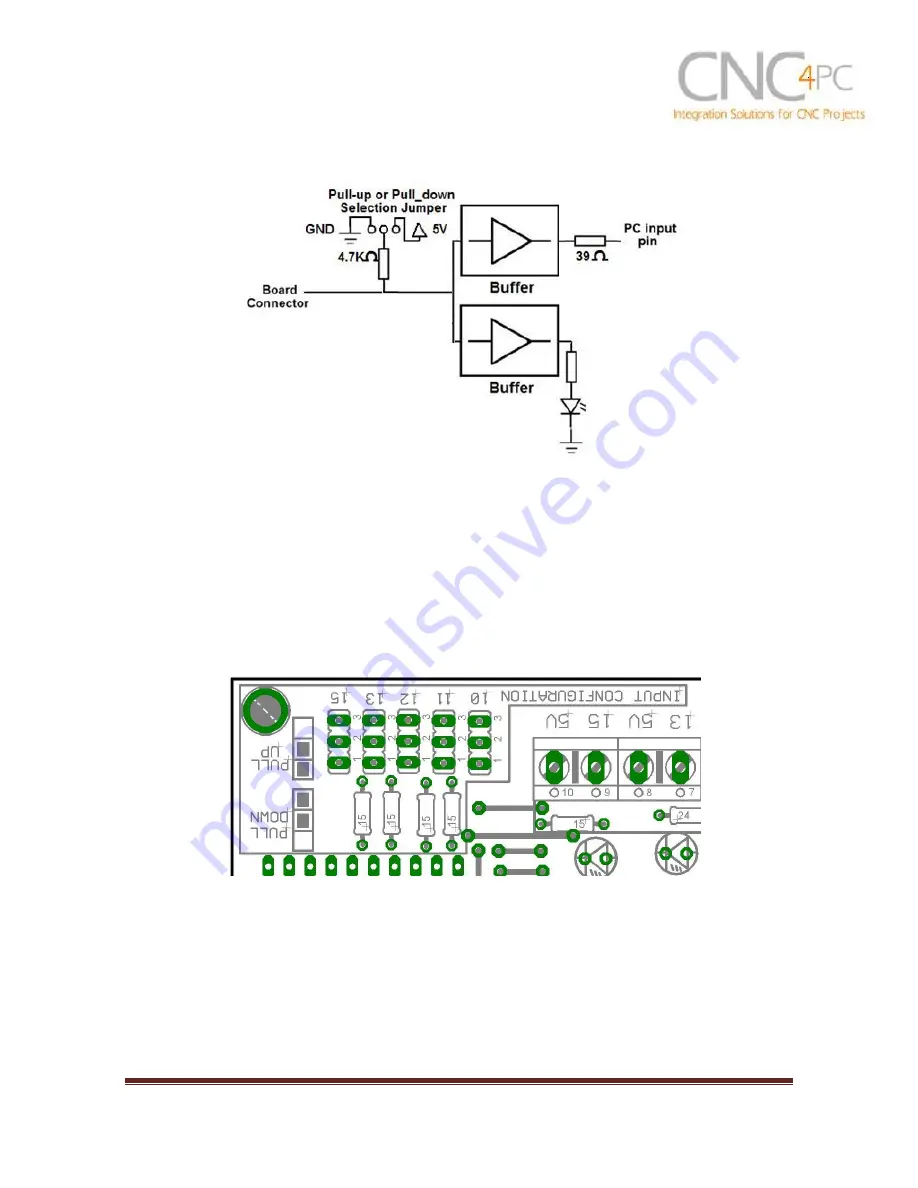

Fig. 3 Simplified functional block diagram for the inputs.

Pins 10, 11, 12, 13 and 15 can be set to pull-down or pull-up by selecting the

jumper in the appropriate position.

The input pins can be set to be pulled up or down with a 4.7Kohm resistor.

1-2: PULL-UP

2-3: PULL- DOWN

5. Special Functions

5.1 Safety

Charge Pump “SCHP”. (Pin 17)

This board takes advantage of Mach ability to send a specific frequency through

one of the pins of the parallel port when the program is in control of the system.

CNC machinery can be very dangerous, and you could have a risk of the machine