S-2R + Frontanbau 11.2018 en

16

For all maintenance and repair work on the lift cylinder, the lifter must be cleared of

all attachments and tools. Hydraulic lines of the lift must be pressure-free.

After the first 5 hours of operation, all bolts should be checked for tightness, then

every 20 hours of operation.

The hydraulic plugs and sockets must be kept clean. As soon as the hydraulic lines are

uncoupled, close with the corresponding dust protection.

When cleaning the column lifter with a high-pressure cleaner, please ensure that the high-

pressure jet is not directed at bearings and sealing points or hydraulic connections. This can

lead to damage and premature failure.

Please use only sulfur-free grease.

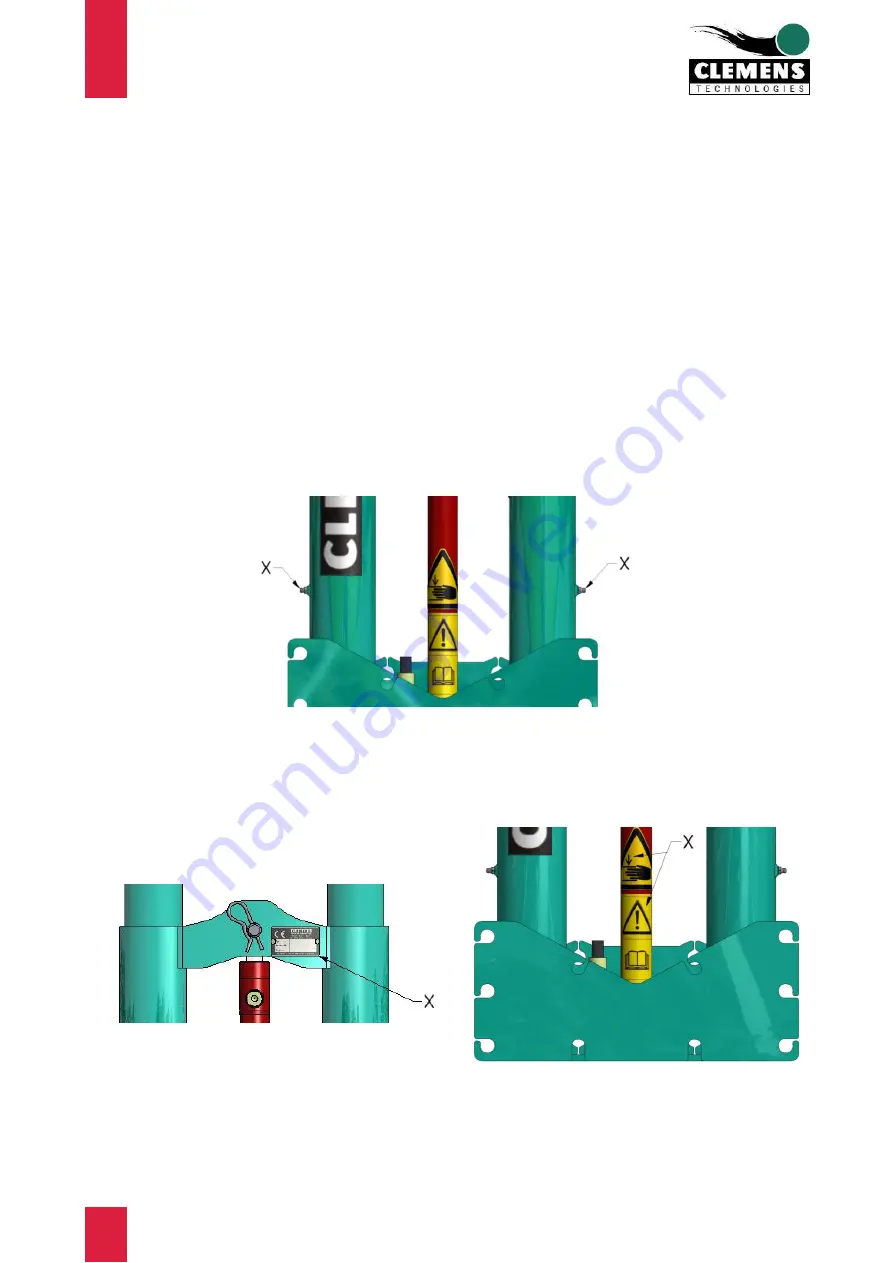

At the marked points "X", the guideways must be

greased no later than every 8 working hours and after each cleaning. Articulated joints must

be greased every 50 working hours. Larger accumulations of grease that could come loose

during operation or during transport must be removed.

Figure 5 Lubrication points

If the pictograms or the nameplate are damaged, they must be replaced at the points

marked "X".

Figure 7 Position of the stickers

Figure 6 Position of the nameplate