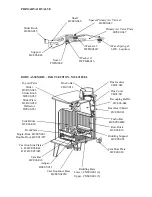

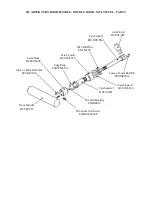

Riddling Grate

Your Cleanburn Stove is fitted with a locomotive type grate.

So that de-ashing can be carried out cleanly and easily, it is

riddled from the outside of the stove with the doors closed.

To obtain the best response from the air controls, the grate

should be in the open position during normal burning.

Lighting the Stove

We recommend that you have two or three small fires before

you operate your stove to its maximum heat output. This is to

allow the paint to cure in steadily and to give a long service

life of the paint finish. During this curing in process you may

notice an unpleasant smell. It is non-toxic, but for your

comfort we would suggest that during this period you leave

all doors and windows open.

First, load the fire with starting fuel, i.e. paper, dry sticks

and/or firelighters in the mode chosen, either wood or solid

mineral fuel. Light the fire at the base leaving all air controls open. It may be necessary to leave the

door ajar for up to 5 minutes. After a further 5 minutes, the primary air can be closed. Allow the

fuel to reach a steady glow and build the fire up gradually. Once you have a good fire established

across the grate bed, further fuel can be added as required.

Air Controls

Wood burns most efficiently with the primary control in the closed position and the secondary

control approximately 50% open. Moving the secondary control will control the burn rate of the

stove.

When refuelling the stove, the primary air should be opened for 2-3 minutes to ensure clean ignition

of the new fuel.

Loading the Stove

Wood burns best on a bed of ash and it is therefore only necessary to remove surplus ash from on

top of the grate occasionally. Do not let the ash level under the grate reach above the primary air

inlet holes. If allowed to build-up, ash will stifle the airflow through the grate.

Reduced Combustion

In order to reduce the rate of combustion, close the primary air lever and then the secondary air

lever by moving the handles all the way to the left. If the controls are left in this position, the fire

will be starved of air and will burn more slowly. If you want to revive the fire it is recommended

that the primary air control is open first, then open the secondary air slider.

Warning!-

The stove will remain

hot

for a considerable time after the fire has been extinguished.

Recommended Fuels

Cleanburn Stoves recommend wood logs be burnt in this appliance. Burn only dry, well-seasoned

wood, which should have been cut, split and stacked for at least 12 months, with free air movement

around the sides of the stack to enable it to dry out. Burning wet or unseasoned wood will create tar

deposits in the stove and chimney and will not produce a satisfactory heat output.

Only authorised fuels may be used in UK smoke control areas. A list of authorised fuels can be

found at

http://uksmokecontrolareas.co.uk/fuels.php

Warning!-

Petroleum coke fuels or household waste must not be burnt on this appliance.