Page 29 of 41

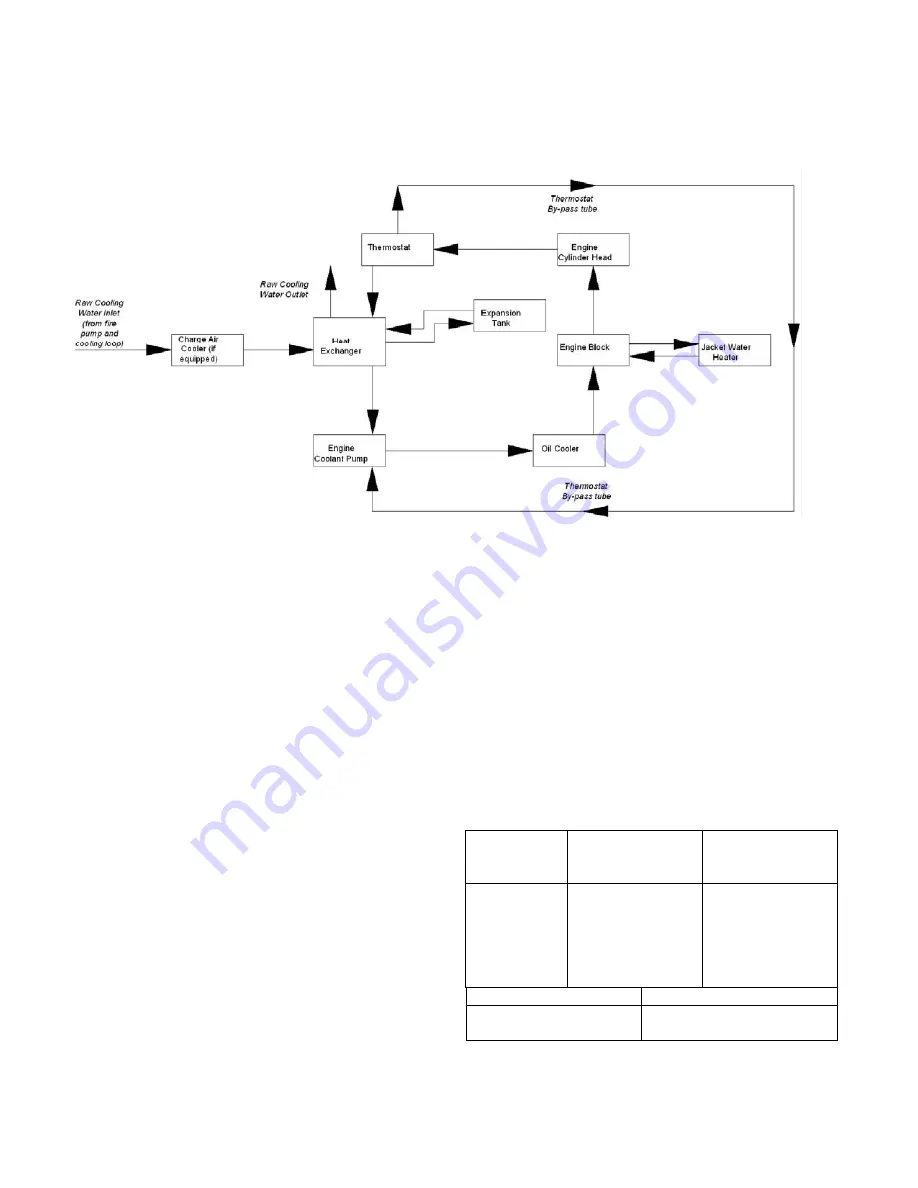

On heat exchanger equipped engines raw cooling

water flows through the tube side of the charge air

cooler, if equipped, and the tube side of the heat

exchanger.

Refer to

Figures #35E

for ZF6H engine models for

cooling system flow path diagrams.

Figure #26A – ZF6H engine models

3.4.9 IMPORTANT SERVICE NOTICE

Any time an engine experiences a high coolant

temperature alarm condition the primary cause of the

overheat must be determined and the cause corrected

to prevent a recurring overheat event.. Additionally,

if an event of a restricted flow, collapsed hose,

insufficient coolant level or failed pressure cap is

experienced, further investigation of the cooling

system is required.

1) The coolant shoud be drained (after de-

energizing the coolant heater

2) Replace the engine thermostat(s)

3) Remove the engine water pump and

inspect the impeller and seal for damage, replace as

necessary. Reassemble and refill coolant according

to the Installation and Operations Instruction Manual.

4) Run the engine to verify normal operating

temperature.

3.4.9.1 Cavitation

Cavitation is a condition that occurs when bubbles

form in the coolant flow in the low pressure areas of

the cooling system and implode as they pass to the

higher pressure areas of the system. This can result in

damage to cooling system components, particularly

the water pump impeller and cylinder liners.

Cavitation in an engine can be caused by:

Improper coolant

Restricted coolant flow caused by collapsed

hose or plugged system

Coolant fill cap is loose or unable to retain

the required pressure

Insufficient fluid level

Failure to de-aerate

Overheat

3.5

ELECTRICAL SYSTEM

3.5.1

Wiring Diagrams (Only with Engine Gauge

Panel)

Run/Stop

Solenoid

Drawing No.

Description

(DC Voltage)

ETS =

Energized to

Stop

C072145

Mechanical

Engines NFPA-20

and UL/FM engine

gauge panel

Drawing No.

Description (AC Voltage)

C07651

NFPA-20 and UL/FM

Engine Jacket Water Heater

Figure #27