Page 12 of 41

This section of the manual should be read in

conjunction with the relevant Installation and

Operation Data Sheets. If there is any doubt about an

installation, contact should be made with Clarke

Customer Support giving exact details of the

problem.

All installations should be clean, free of any debris

and dry. Care should be taken to ensure that there is

easy access to the engine for maintenance and repair.

The safety of personnel who may be in the area of the

engine when it is running is of paramount importance

when designing the installation layout.

1)

Secure pump set to foundation and complete

installation in accordance with pump

manufacturer’s instructions. Perform engine

to pump coupling alignment. Lubricate Falk

coupling with supplied grease or driveshaft

universal joints with NLGI grade #1 or #2

grease at the (3) Zerk fittings. (Refer to

section 2.4 for specific alignment

instructions).

2)

Engine with Heat Exchanger Cooling: Install

the heat exchanger discharge pipe. The

discharge pipe should be no smaller than the

outlet connection on the heat exchanger.

Discharge water piping should be installed in

accordance with applicable codes. All

plumbing connecting to the heat exchanger

must be secured to minimize movement by

the engine. Cooling loop water pressure to

the heat exchanger must not exceed the limit

that is stated on the heat exchanger supplied

with the engine.

3)

Install all engine cooling system draincocks

and plugs.

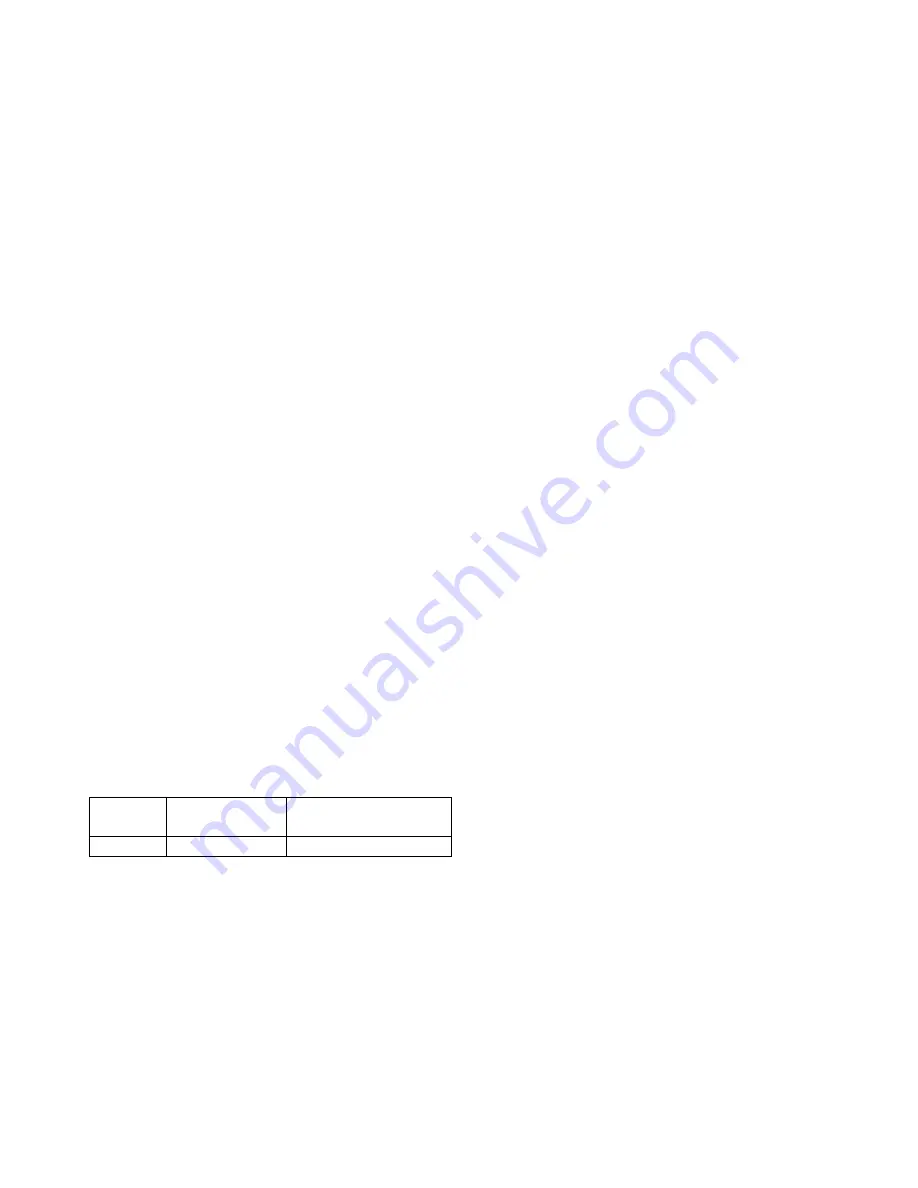

Qty

Description

Location

1

1/8” Draincock

Heater Inlet Tube

4)

Engine is typically provided with premixed

coolant installed. If engine is not provided

with coolant or there is a need to top off, fill

engine cooling system with premixed 50%

water / 50% coolant solution. Use only

coolants meeting ASTM-D6210

specifications for heavy-duty diesel engines.

Never use light-duty or automotive coolants

in the engine that are stated as ASTM-D3306

only. Refer to

Figure #23

in section 3.4.3

for cooling system capacity. Refer to section

3.4.5 filling procedure.

5)

Engine is shipped with oil

installed

. For

make-up oil specifications refer to section

3.3 Lubrication System.

6)

Connect fuel supply and return line to fuel

supply tank plumbing. Reference the Fuel

System section of the Installation and

Operation Data (see Page 5), for piping size,

maximum allowable fuel pump suction, and

maximum allowable fuel head requirements.

Fill supply tank with

ONLY

#2 diesel fuel

(ASTM D-975) or BS 2869 Class A2 “Red”

diesel fuel, bleed supply system of air and

check for leaks.

CAUTION:

Biodiesel fuel

is not recommended or stand-by equipment

that can have minimal fuel consumption

(such as standby generators, fire protection,

etc.) For standby applications use only

petroleum based diesel fuel with DEUTZ

approved conditioners/additives. For fuel

conditioners/additives check with your local

DEUTZ dealer, or Clarke. Fuel supply level

must meet applicable code requirements. Do

not use a copper based or galvanized material

for any component of a diesel fuel system.

The fuel will chemically react with the zinc

resulting in clogged fuel filters and injector

systems.

7)

Remove protective covering on air cleaner

element.

8)

Connect jacket water heater (if supplied) to

AC power source. Connect the supplied

heater connection wire directly to a customer

supplied electrical junction box. The

electrical supply requirements are indicated

on the connection box. Connect to the heater

directly to the junction box at the end of the

heater only.

Supply wiring should never be

routed through the engine gauge panel

.

Severe damage to critical engine control

components could result. Energize heater

only after step #4 is completed.

9)

Connect exhaust system to flexible

connection on the engine. The exhaust

system plumbing must be supported by the

building structure and not the engine. The

exhaust flexible connection is provided only

for the purpose of thermal expansion and

vibration isolation, not for misalignment or

directional change.

10)

Make electrical DC connections between the

engine gauge panel terminal strip (if

supplied) and the controller per the controller

manufacturer’s instructions. Refer to the