21

TROUBLE SHOOTING

Your Clarke Mig Welder has been designed to give long and trouble free service. If,

however, having followed the instructions in this booklet carefully, you still encounter

problems, the following points should help identify and resolve them.

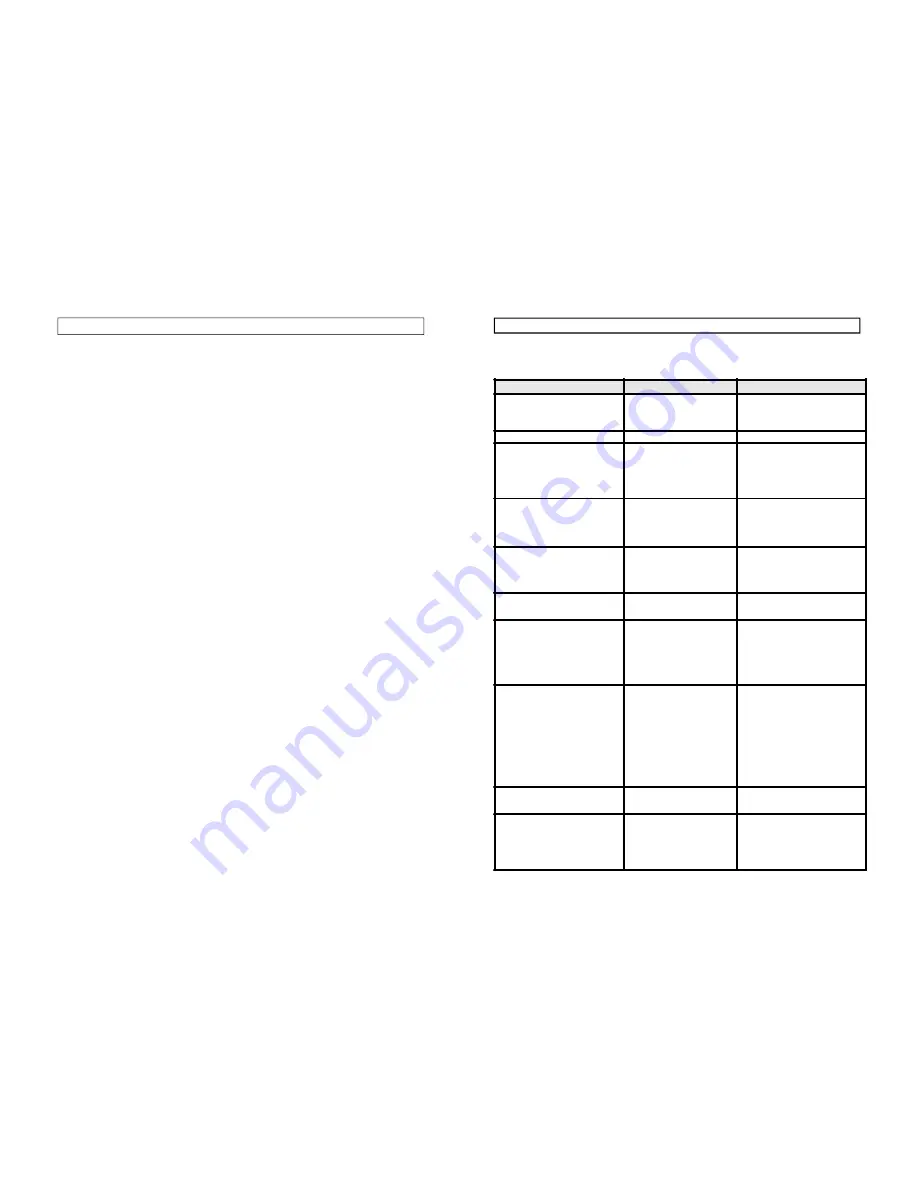

PROBLEM

PROBABLE CAUSE

POSSIBLE SOLUTION

1. No "life" from the welder

Check fuses and mains lead.

a) Replace fuses as necessary. If

problem persists, return welder to

your local dealer.

b) Check fuse size.

2. No wire feed

Motor malfunction

Return welder to your local dealer.

3. Feed motor operates but wire

will not feed

a ) i n s u f f i c i e n t f e e d r o l l e r

pressure

b) Burr on end of wire

c) Linerblocked or damaged

d) Inferior wire

a) Increase roller pressure

b) Re-cut wire square

c) Clear with compressed air or

replace liner.

d) Use only good clean wire

4. Wire welds itself to tip

a) Wire feed speed too low

b) Wrong size tip

a) Unscrew tip, cut wire and

fitnew tip. Increase wire speed

before operating again.

b) Change tip size.

5. Wire feeds into "bird's" nest

tangle.

a) Wire welded to tip.

b ) W i r e l i n e r d a m a g e d

preventing smooth operation.

a) As above plus reduce feedroller

pressure so that if blockage occurs

wire sleeps on roller. i.e. no feed

b) Renew wire liner.

6. Loose coils of wire

tanglearound wire druminside

machine

Drum brake too slack.

Tighten drum brake - DO NOT

OVERTIGHTEN

7. Erratic wire feed

a) Drum brake too tight

b) Feed roller worn

c) Insufficient pressure on

feed roller

d) Wire dirty, rusty, damp or

bent

d) Liner partilly blocked

a) Loosen drum brake slightly

b) Checkand replace if necessary

c) Increase pressur eon feed roller

DO NOT OVERTIGHTEN

d ) Re-cut wire and ensure it i s

clean

e) Clear with compressed air

8. Poor quality welds

a) Insufficient gas at weld area

b ) I n c o r r e c t g a s / w i r e

combination

c) Rusty, painted, damp, oily or

greasy workpiece

d) Rusty, dirty wire.

e) Poor earth contact

a ) Check that gas is not being

b lown a w a y b y draughts, i f s o ,

m o ve to a sheltered area. If no

draught, incrtease gas supply.

b ) C o n s u l t y o u r M i g W e l d i n g

manual

c) Ensure workpiece is clean and

dry

d) Ensure wire is clean and dry

e) Check ground clamp/workpiece

connection.

9. Wire jams in tip when welding

aluminium

Tip too small

Use slightlyoversize tip i.e. fo r

0.8mm wire use 1mm tip (Applies

to aluminium only)

10.Welder cuts out whilst in use

Duty cycle exceeded (auto

cut-out operates)

Allow welder to cool for 15-30min.

before continuing. Note if duty

cycle is continually e x c e e d e d ,

damage to the welder may result

and welder output is probably too

small for application.

WELDING HINTS AND MAINTENANCE

1

Always weld clean, dry and well prepared material.

2

Hold gun at a 45° angle to the workpiece with nozzle about 6mm from the

surface.

3

Move the gun smoothly and steadily as you weld.

4

Avoid welding in very draughty areas. A weak pitted and porous weld will

result due to air blowing away the protective welding gas.

5

Keep wire and wire liner clean. Do not use rusted wire.

6

Sharp bends or kinks on the welding hose should be avoided.

7

Always try to avoid getting particles of metal inside the machine since they

could cause short circuits.

8

If available, use compressed air to periodically clean the hose liner when

changing wire spools

IMPORTANT: Disconnect from power source when carrying out this operation.

9

Using low pressure air (20-30 PSI), occasionally blow the dust from the inside

of the welder. This keeps the machine running cooler. Note: do not blow air

over the printed circuit board and electronic components.

10

The wire feed roller will eventually wear during normal use. With the correct

tension the pressure roller must feed the wire without slipping. If the pressure

roller and the wire feed roller make contact (when the wire is in place between

them), the wire feed roller must be replaced.

11

Check all cables periodically. They must be in good condition and not cracked.

Содержание Weld 215TE

Страница 1: ...1 Model Nos 215TE 250TE 260TE OPERATING MAINTENANCE INSTRUCTIONS 0100...

Страница 16: ...31 WIRING DIAGRAM MIG 260TE Part No 6010390...

Страница 17: ......