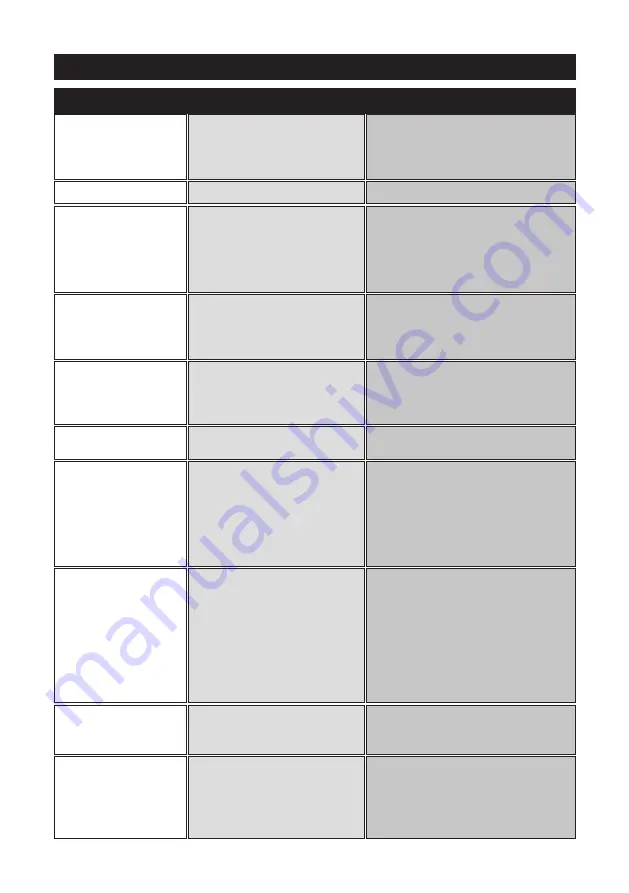

23

a) insufficient feed roller

pressure

b) Burr on end of wire

c) Liner blocked/damaged

d) Inferior wire

TROUBLE SHOOTING

1. No life from

welder

2. No wire feed

Check fuses and mains lead

a) Replace fuses as necessary.

If problem persists. return welder

to your local dealer.

b) Check fuse size.

Return welder to your local dealer.

Motor malfunction

a) Increase roller pressure

b) Re-cut wire square

c) Clear with compressed air or

replace liner.

d) Use only good dean wire

a) Unscrew tip cut wire and fit new

tip. Increase wire speed before

operating again.

b) Change tip size.

a) As above plus reduce feed roller

pressure so if blockage occurs

wire sleeps on roller. i.e. no feed

b) Renew wire liner.

Tighten drum brake DO NOT

OVERTIGHTEN

3. Feed motor

operates but wire

will not feed

4. Wire welds itself to

tip

a) Wire welded to tip.

b ) Wire liner damaged

preventing smooth

operation.

a) Wirefeed speed too low

b) Wrong size tip

5. Wire feeds into

birds nest tangle.

6. Tangled coils of

wire around drum

7. Erratic wire feed

8. Poor quality welds

9. Wire jams in tip

when welding

aluminium

Drum brake too slack.

a) Drum brake too light

b) Feed roller worn

c) Insufficient pressure on

feed roller

d) Wire dirty, rusty, damp or

bent

e) Liner partially blocked

a) Loosen drum brake slightly

b) Check and replace if necessary

c) Increase pressure on feed roller

DO NOT OVER TIGHTEN

d) Re-cut wire and ensure it is clean

e) Clear with compressed air

a) Check gas is not being blown

away by draughts, if so, move to

a sheltered area. If no draught,

increase gas supply.

b) Consult Mig Welding manual

c) Ensure wkpiece is clean and dry

d) Ensure wire is clean and dry

e) Check ground clamp/ wkpiece

connection.

Use slightly oversize tip i.e. for 0.8mm

wire use 1mm tip (Applies to

aluminium only)

Allow welder to cool for 10-30min

before continuing.

Note: If duty cycle

is continually exceeded, damage to

welder may result and welder output

is probably too small for application,

a) lnsufficient gas at weld

area

b) Incorrect gas/wire

combination

c) Rusty, painted, damp. oily

or greasy work piece

d) Rusty, dirty work.

e) Poor earth contact

Tip too small

Duty Cycle exceeded (auto

cut-out operates)

10. Welder cuts out

whilst in use

PROBLEM

PROBABLE CAUSE

REMEDY

Содержание 195TEC

Страница 1: ...MIG WELDER OPERATING MAINTENANCE INSTRUCTIONS Model Nos 195TEC 205TE 230TEC 0820 ISS6...

Страница 23: ...24 PARTS DRAWING MIG 195TEC...

Страница 25: ...26 PARTS DRAWING MIG 205TE...

Страница 27: ...28 PARTS DRAWING MIG 230TEC...

Страница 29: ...30 WIRING DIAGRAM MIG 195TEC MIG 230TEC...

Страница 30: ...WIRING DIAGRAM MIG 205TE 31...

Страница 31: ...DECLARATION OF CONFORMITY...

Страница 32: ......