OPERATION

Structural Limits

Operating conditions, such as speed, fluid viscosity, inlet pressure, discharge pressure, temperature,

filtration, duty cycle, mounting etc. are interrelated. Due to these variable conditions, specific application

limitation may be different from structural limitations. This equipment must not be operated without

verification that operating requirements are within its capabilities.

CAUTION

ATTENTION

Under no circumstances are the following structural limitations to be exceeded:

Maximum Inlet Pressure ................................................................................................... 50 PSIG

Maximum Discharge Pressure:

Series 110 ...................... 400 PSI (1500 SSU max., 40 SSU min. viscosity at pumping temp.)

Series 210 ...................... 400 PSI (1500 SSU max., 40 SSU min. viscosity at pumping temp.)

Maximum Fluid Temperature ................................................................................................ 240°F

INSPECTION AND PARTS LIST

Intervals for inspection and replacement of wear parts will vary greatly with the properties of pumped fluid

and can only be determined by experience. All internal parts of unit are lubricated and cooled by pumped

fluid. Fluid that contains abrasive materials or is corrosive will significantly reduce service life and require

shorter service intervals. Wear in pump will normally show as vibration, noise, and loss of capacity or

reduction in flow or pressure.

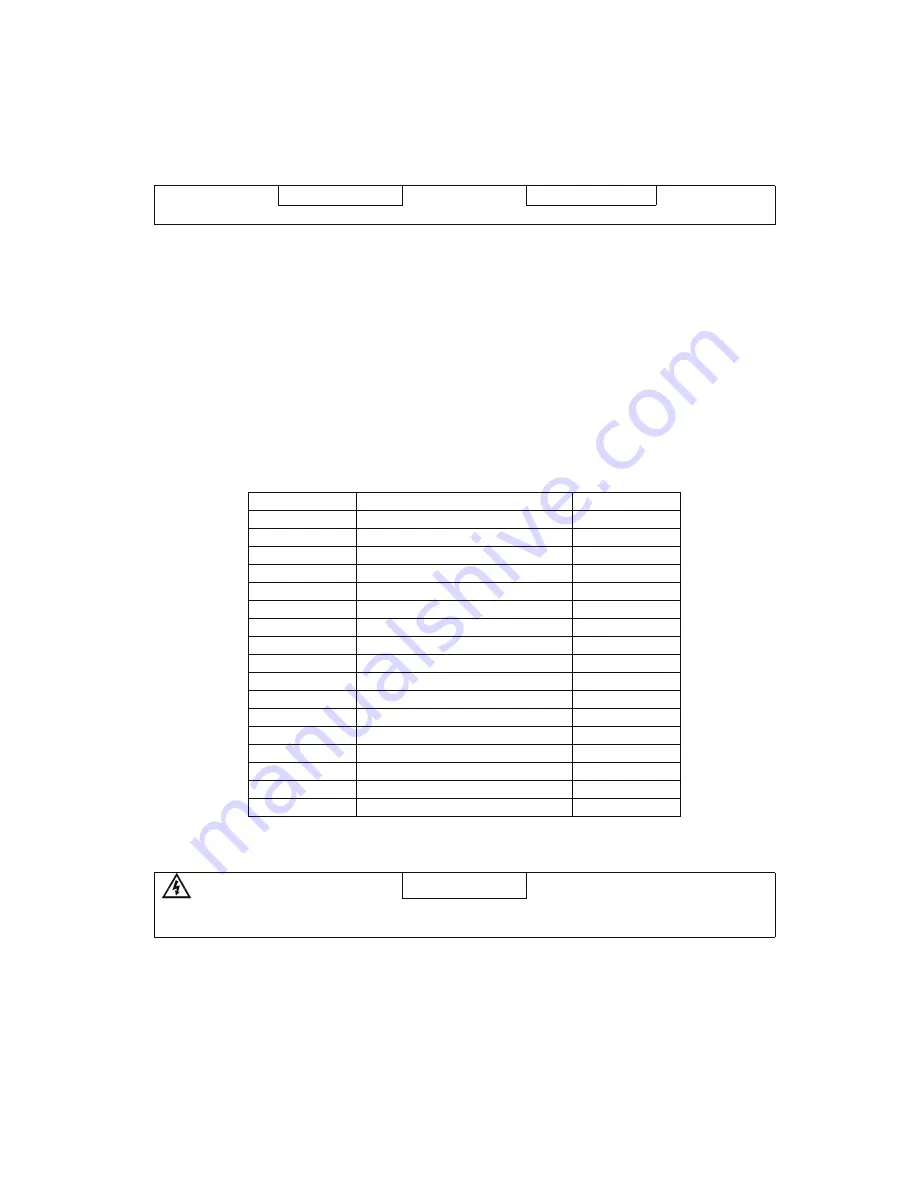

Table 1 – Pump Parts List

IDP DESCRIPTION

QTY

118 Orifice

1

201 Housing

1

202 Inlet

1

203 Hex

Bolt

4

204 Outlet

1

205 Hex

Bolt

4

207 Lock

Washer

4

208

Balance Piston Bushing

1

213 Key

1

216 Bearing

1

217 Truarc

Ring

2

222 Retainer

1

223 Cap

Screw

4

311 Power

Rotor

1

314

Idler Rotor Assembly

2

409 O

Ring

2

432 O-Ring

1

MAINTENANCE

WARNING

BEFORE working on equipment, make sure all power to the equipment is

disconnected.

GENERAL

: To perform maintenance on canned motor pump, the following initial conditions shall be

completed prior to maintenance action. Close inlet and outlet valves and tag “Out of

Service”. De-energize pump drive motor and vent all pressure from pump. Remove drain

plug (105) and drain fluid from pump and motor.

NOTE:

Part numbers contained within parenthesis such as (103) refer to the balloon numbers as shown

on Figure 3 and the IDP numbers in Table 1.

3

Содержание IMO 110

Страница 7: ...Figure 4 5...