INSTALLATION

WARNING

This Equipment is limited to handling fluids compatible with motor windings and

insulation. Provide suitable safety and emergency systems to protect personnel

and property from injury due to pump malfunction, If pump handles hazardous

fluids, provide for safety in event of pump leakage or malfunction.

CAUTION

ATTENTION

Piping to pump MUST be independently supported and not allowed to impose

strains on case. Piping connections should be flexible whenever possible and

make provision for expansion and contraction due to temperature change. Piping

connections must not impose more than 1 times “API” forces and moments on inlet

and outlet.

Inlet Position

The pump inlet flange may be positioned in increments of 90° from position shown on assembly drawing.

To change position of flange, remove socket head cap screws (203) and lock washers (207). Rotate

housing (201) and inlet head (202) as a unit taking care not to damage O-ring (409). Replace socket head

cap screws with lock washers and torque to value on assembly drawing depending on pump type. Care

must be taken to not disengage pump shaft (311) from motor shaft . If this occurs, ensure key (213) is in

place and properly related before re-engaging shafts.

Suction Line

The suction line should be as short as possible. A suction line one size larger than pump inlet is

recommended. All joints in suction line must be tight and sealed. This prevents air from being drawn into

a pump with negative suction pressure or leaks from pump or line with positive pressure.

Suction Strainer

A suction strainer of at least 100 mesh with a flow capacity of 30 - 50 gpm and a pressure drop not

exceeding 0.5 psi ( when newly installed) should be used. (Inlet strainer shall be sized to insure that

pressure at inlet port of pump will not, under any circumstances, exceed 10 inches of mercury vacuum.)

Maintenance instructions shall provide for periodic cleaning or replacement of inlet strainer.

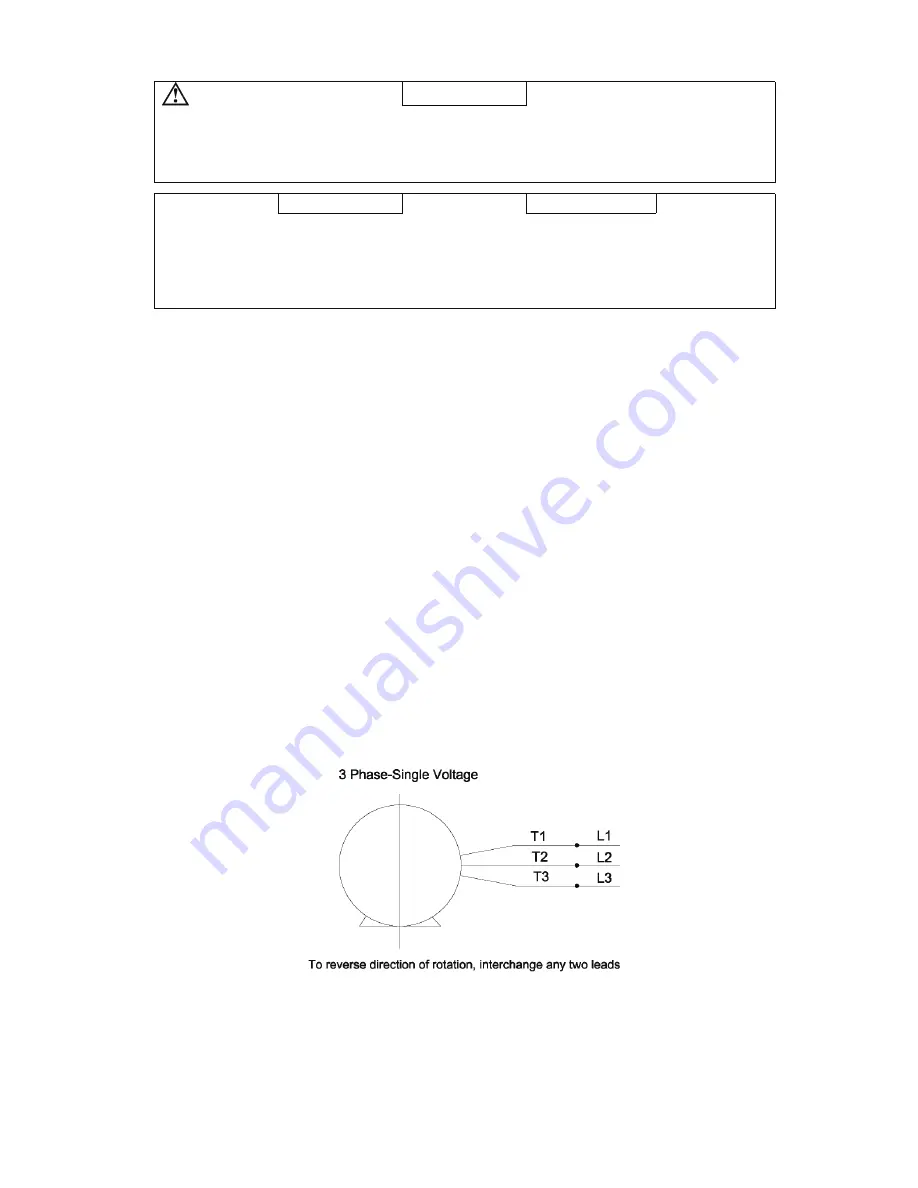

Electrical Connections

A label giving the electrical wiring connections for canned motor pump is located under conduit box cover

and in Figure 3. Note that extended reverse rotation can cause pump damage.

Figure 3 – Motor Wiring Connections

Rotation

Before attempting to operate pump, rotation must be verified. It is suggested that this can best be

accomplished with a Phase and Motor Rotation Tester such as AVO Biddle Instruments Catalogue No.

560060 / 560400 (510 Township Line Road, Blue Bell, PA 19422 USA). Follow instrument manufacture’s

instructions to determine proper motor/pump rotation.

2

Содержание IMO 110

Страница 7: ...Figure 4 5...