EN - 55

Code

000

Code

100

Net

3bl

COM

adr

000

COM

adr

010

COM

adr

011

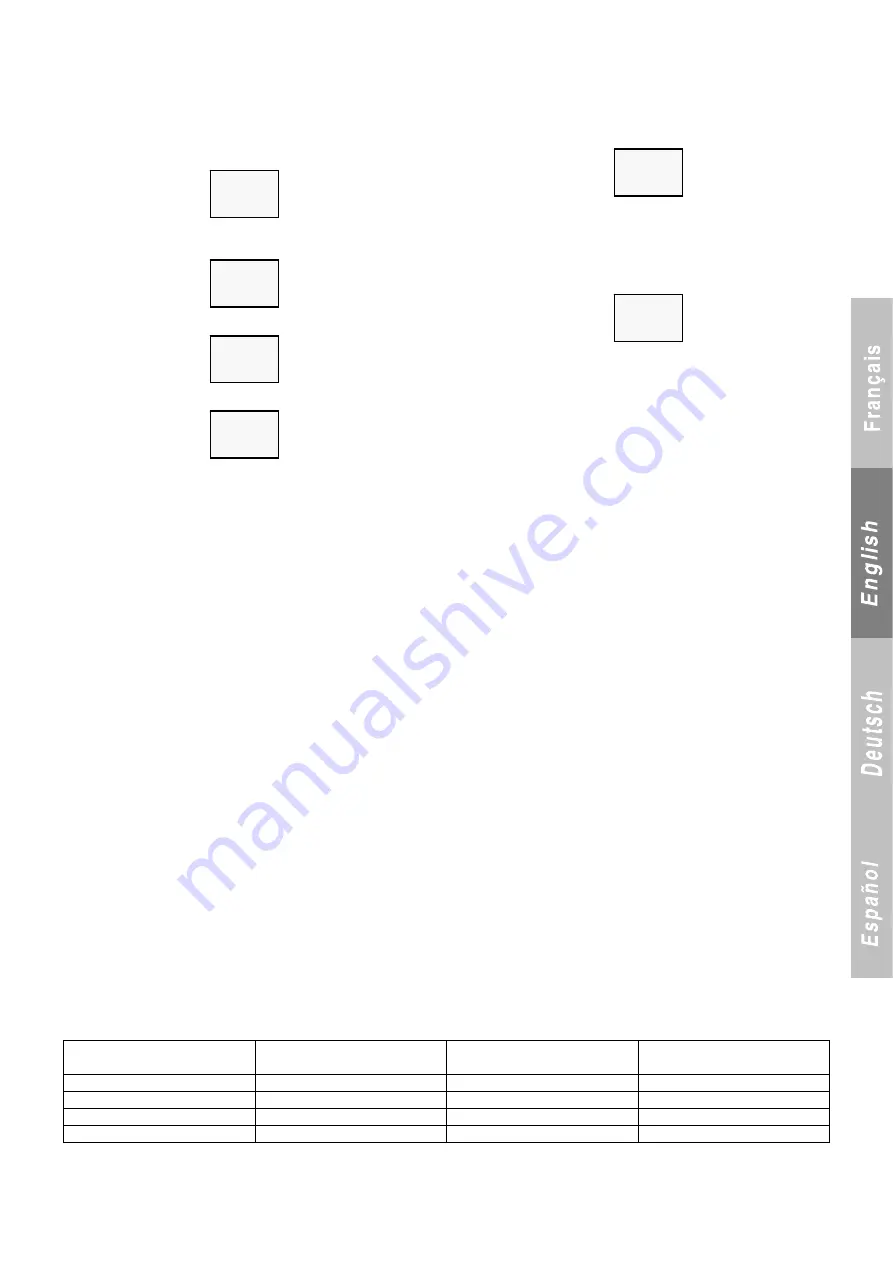

22 ASSIGNING A COMMUNICATION ADDRESS TO THE DIRIS ENERGY METER

Follow the procedure described below when replacing a DIRIS

energy meter already installed on a machine.

Turn on the meter and press the PROG button for 5 seconds. The

following message is displayed:

Press the P PF button until the 0 on the left starts flashing. Press

the

▲

or

▼

button until the following screen appears:

Confirm by pressing

OK

. The following message appears:

Press the

▲

or

▼

button until the following message appears:

Now press the P PF button twice so that the 0 in the middle starts

flashing. Press

▲

or

▼

until 1 appears on the display.

If the DIRIS meter is installed on a 2-circuit machine, confirm by

pressing

OK

then exit the configuration menu by pressing the

PROG

button for 5 seconds.

If the DIRIS meter is installed on module 2 of a 3-circuit machine,

press the P PF button a third time so that the 0 on the right starts

flashing. Select 1 so that the message is as follows:

Confirm by pressing OK and exit the configuration menu by

pressing the PROG button for 5 seconds. The measured values will

appear on the display.

Now enter the measured values menu of one of the circuits and

make sure that the electrical quantities screen (last screen) appears

when P15 = Yes. If so, communication between the meter and the

controller has been established. If the screen does not appear,

check the continuity of the Bus.

23 MANAGEMENT OF THE PROTECTIONS FOR 3-CIRCUIT AIR-TO-WATER UNITS (MODULES 1

AND 2)

- A link fault between modules 1 and 2 may indicate that the RS485

cable is not connected correctly or a lack of voltage on module 2

(circuit 3 off only).

- It is recommended to energise both modules at the same time to

ensure adequate warming of the oil before starting up the machine

and to prevent the time delays on each module from activating

together.

- The oil warm-up time is activated if module 1 and module 2 do not

turn on (link fault).

- Phase controller, water flow, and water outlet faults are managed

independently for each module. They only shut off the module on

which they occur, not the entire machine.

- Water outlet sensor faults are also managed independently on the

two modules. Also, if the manifold water outlet sensor is controlled

and a fault occurs on the sensor, module 1 switches to standalone

mode and uses its own water outlet sensor to make adjustments.

Other faults (compressor, electronic expansion valve, high

pressure, low pressure, discharge, desuperheat, lubrication and

freon frost protection) are managed on the 2-circuit machines and

only affect the refrigerating circuit in question.

24. TIME SCHEDULES

24.1 Overview

This function is used to manage liquid chillers on a weekly basis by

selecting:

- 6 program steps (maximum).

- 6 holiday bands (maximum).

24.2 Definition of program steps

Settings:

- Start time,

- End time

- Selected days (M.T.W.T.F.S.S)

- Control mode: setpoint 1 - off/setpoint 2 - off/setpoint 1 - setpoint

2/setpoint 2 - setpoint 1/disabled.

Default setting:

- Start time: 00.00

- End time: 00.00

- Enabled days: none

- Control mode disabled.

24.3 Definition of holiday bands.

Settings:

- Band type: Disabled, off, operate per setpoint 1, operate per

setpoint 2.

- Start date dd-mm

- End date dd-mm

- Default setting: Disabled, from 01-01 to 01-01

24.4 Operation

- When the controller is powered up or the time is set, the unit

status information is updated to reflect the schedule settings.

- Users may change the unit's settings (on/off - setpoint 1 or 2

control). However, if a time range or holiday band is on, this

information is updated at the start or end of the schedule.

- If at least one time range or holiday band is enabled, parameter

P120 is set to '2 via console or BMS' and cannot be modified.

- The schedule is disabled when test mode is activated. The unit

status information is updated to the schedule settings when test

mode is deactivated.

- If periods or bands overlap, On takes priority over Off and setpoint

1 takes priority over setpoint 2

- If a program step is active (

#

disabled) and the current day is selected, the unit status is as follows :

Program type

State before start time

State between start time

and end time

State after end time

STP1-off

Off

Start per setpoint 1

Off

STP2-off

Off

Start per setpoint 2

Off

STP1-STP2

Start per setpoint 2

Start per setpoint 1

Start per setpoint 2

STP2-STP1

Start per setpoint 1

Start per setpoint 2

Start per setpoint 1