1. General Safety Rules

Warning!

Do not attempt to operate this machine until you have thoroughly read and understood all of

the instructions, rules and other information contained in this manual. Failure to comply can

result in accidents involving fire, electric shock or serious personal injury. Maintain this

manual and review frequently for the continued safe operation and for possible instructing

third party operators.

1.

Know your tool

–

For your own safety, read the manual carefully, learn the applications

and limitations of the machine as well as the specific potential hazards for the machine in

use.

2.

Protect yourself against electric shock by preventing body contact with grounded parts,

for example, pipes radiators etc.

3.

Keep all guards in place and in working order.

4.

Remove any adjustment tools, keys and wrenches, form a habit of checking that all items

are removed from the machine before turning on.

5.

Keep the work area clean.

6.

Don’t use in dangerous environments, don’t use any power tools in damp or wet locations

or expose them to rain. Keep the work area well lit.

7.

Keep children away from the machine, all visitors must be kept a safe distance from the

work area.

8.

Make the workshop child proof, use padlocks on the master switches or remove the

starter keys when the machine is not in use.

9.

Do not force a tool to complete a job it was not designed to do.

10.

Wear the correct clothing and safety items, do not wear loose clothing, gloves ties or

jewellery that could be caught in the moving parts. Wear a safety hat or a hair net if you

have long hair.

11.

Always use safety glasses when operating machinery and use a dust mask if the cutting

operation is dusty. Normal eyeglasses only have impact resistant lenses and are not safety

glasses.

12.

Secure the workpiece before starting the operation, use clamps or a vice where needed,

it is safer than using your hands and frees both hands to operate the tool.

13.

Do not over reach, keep a proper footing and keep your balance at all times.

14.

Maintain tools and keep them in excellent condition, keep the cutting tools sharp and

clean for the best performance. Follow the instructions for lubricating and changing

accessories.

15.

Disconnect the tool from the power supply before carrying out any service work or when

changing cutting tools.

16.

Avoid accidental starting by making sure that the switches are in the OFF position before

plugging the machine in.

17.

Only ever use the recommended accessories, improper use of accessories may be

dangerous.

18.

Never stand on a tool, you could cause serious injury if the tool is tipped or if the cutting

tool is accidentally contacted.

19.

Check the machine for any damaged parts, a guard or other part that is damaged should

be checked to ensure that it will operate correctly and perform its intended function.

Содержание Coventry Pro

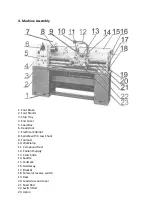

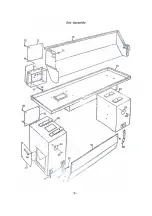

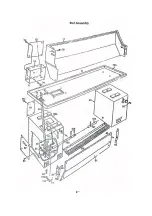

Страница 16: ...Parts List and Diagrams...

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 29: ......

Страница 30: ......

Страница 31: ......

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 43: ......

Страница 44: ......

Страница 45: ......

Страница 46: ......

Страница 47: ......

Страница 48: ......

Страница 49: ......