Note:

For the correct locking condition, each cam must be tightened with the index line between

the two “V” marks on the nose.

Do not interchange chucks or other attachments without first check each cam for the correct

locking position.

To adjust the camlock studs, remove the lock screw B and turn the stud one full turn in or out

as required. Refit and re-tighten the screw B. A datum ring on the camlock stud has been

machined into the stud as a guide to the setting for the camlock studs.

11. Thread and Feed Selection

All threads and feeds are indicated on the table fitted to the top and front of the gearbox and

are selected by using the feed selector handles on the feed box.

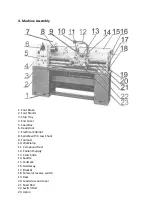

Manual Operation

The carriage is moved by using the handwheel located on the apron, the cross slide is moved

by using the handwheel on the saddle and the compound rest is moved by turning the small

handwheel. The slides can all be anchored by turning the lock bolts on the top of the slide.

Automatic Feed Operation

Engage the feed/thread lever to the feed icon and use the feed selector levers to engage the

feed speeds to start the feed rod. If the feed lever on the apron is then used, pushing the

lever upwards will engage the cross feed, downwards engages the longitudinal feed.

Thread Cutting Operation

The direction of thread cutting is controlled by the feed direction lever and the cutting rate

selected by the feed handles, move the feed/thread lever to the thread cutting icon to engage

the leadscrew. Operate the thread cutting engagement lever (push down) to engage the half

nut with the leadscrew.

12. Lathe Alignment

When the lathe is installed and is ready for use, it is recommended to check the machines

alignment before putting it into operation.

Alignment and levelling should be checked regularly to ensure the continued accuracy of the

machine.

Check the machine as per the following procedure:

Take a steel bar with a diameter of 50mm and a length of

approximately 200mm and lock it in the chuck without using a

centre. Take a cut along approx. 150mm and measure the

difference between A and B. In order to correct a possible

difference, loosen the screw (j) clamping the headstock to the

bed and adjust the position of the headstock using the set screws

and repeat this procedure until the measurements are the same.

Содержание Coventry Pro

Страница 16: ...Parts List and Diagrams...

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 29: ......

Страница 30: ......

Страница 31: ......

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 43: ......

Страница 44: ......

Страница 45: ......

Страница 46: ......

Страница 47: ......

Страница 48: ......

Страница 49: ......