13

advanced and pick attempted 2 times. After tape is advanced 2 times (3 positions

with 6 tries total) with insufficient vacuum, the machine will alarm and stop. It is

suggested to uncheck this function when mounting expensive or difficult parts,

such as cylindrical components;

(11)

Vision centering:

When checked, the center position of a component will be

measured with the vision system to improve placement precision;

(12)

Calibrate:

Opens an additional window to align the component;

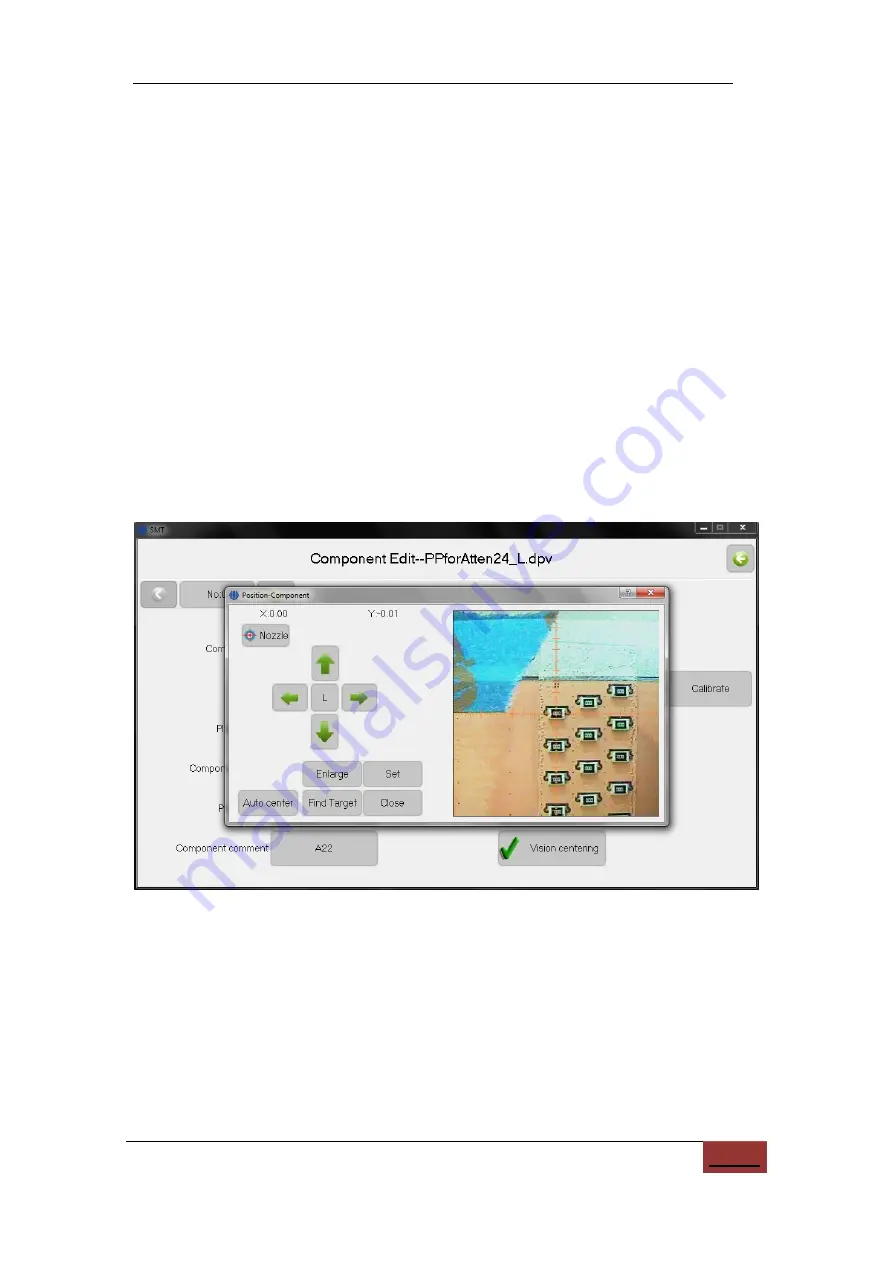

10.1.1.2. Component Calibrate

The component coordinate for placement is normally assigned by software when

importing the CSV file. A more accurate alignment can be made by checking align

component, which sets the position on the PCB using the down camera or nozzle. Its

window is shown below.

Figure 10.4.

Visual alignment for components. Here shown after component placement to

check for placement accuracy.

(1)

X\Y:

The component coordinate offsets are displayed in the upper left;

(2)

Move:

The four arrows move the head. The central button toggles the speed,

which displays either the high or low (H/L) setting;

(3)

Set:

Saves the current X\Y location as the component coordinate;

(4)

Close:

Closes the window;

(5)

Nozzle\Vision:

Clicking this button toggles between nozzle and vision mode.