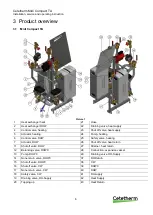

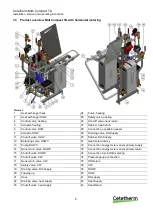

Cetetherm Midi Compact TA

Installation, service and operating instruction

9

4 Installation

4.1 Unpacking

•

Remove the transport packaging and check that the product has not been damaged in transit and that

the consignment agrees with the specifications.

•

When lifting the unit, take care not to apply stress to pipes and heat exchangers as this may weaken

them. Lift the unit in the frame; avoid lifting the unit by holding the heat exchangers. Use pallet lift

where applicable, if using back straps these should be attached to the substructure of the substation.

Note

: Risk of injury lifting heavy objects.

4.2 Preparation

•

Choose a suitable installation area in accordance with official regulations.

The system may generate sounds during operation caused by pumps, regulators systems, flows etc.

This should be taken into consideration during installation of the unit, so that possible operational

sounds affect the surroundings as little as possible.

•

Check the applicable regulations of the district heating supplier. The available differential pressure

should be at least 100 kPa and at most 600 kPa.

Where the differential pressure is higher, a differential pressure controller should be added to the

installation.

•

Flush heating and hot water systems.

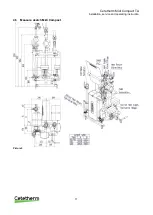

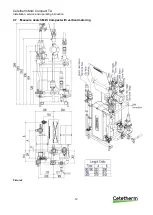

4.3 Mounting

•

Place the substation so that connections, adjustment equipment and safety valves are easily

accessible.

•

Mount the shutoff valves on district heating supply and return. Shutoff valves are not supplied.

•

Connect the pipe works to the connection points, see

•

When executing hot work on or close by the substation, all incendiary components should be

demounted and removed.

•

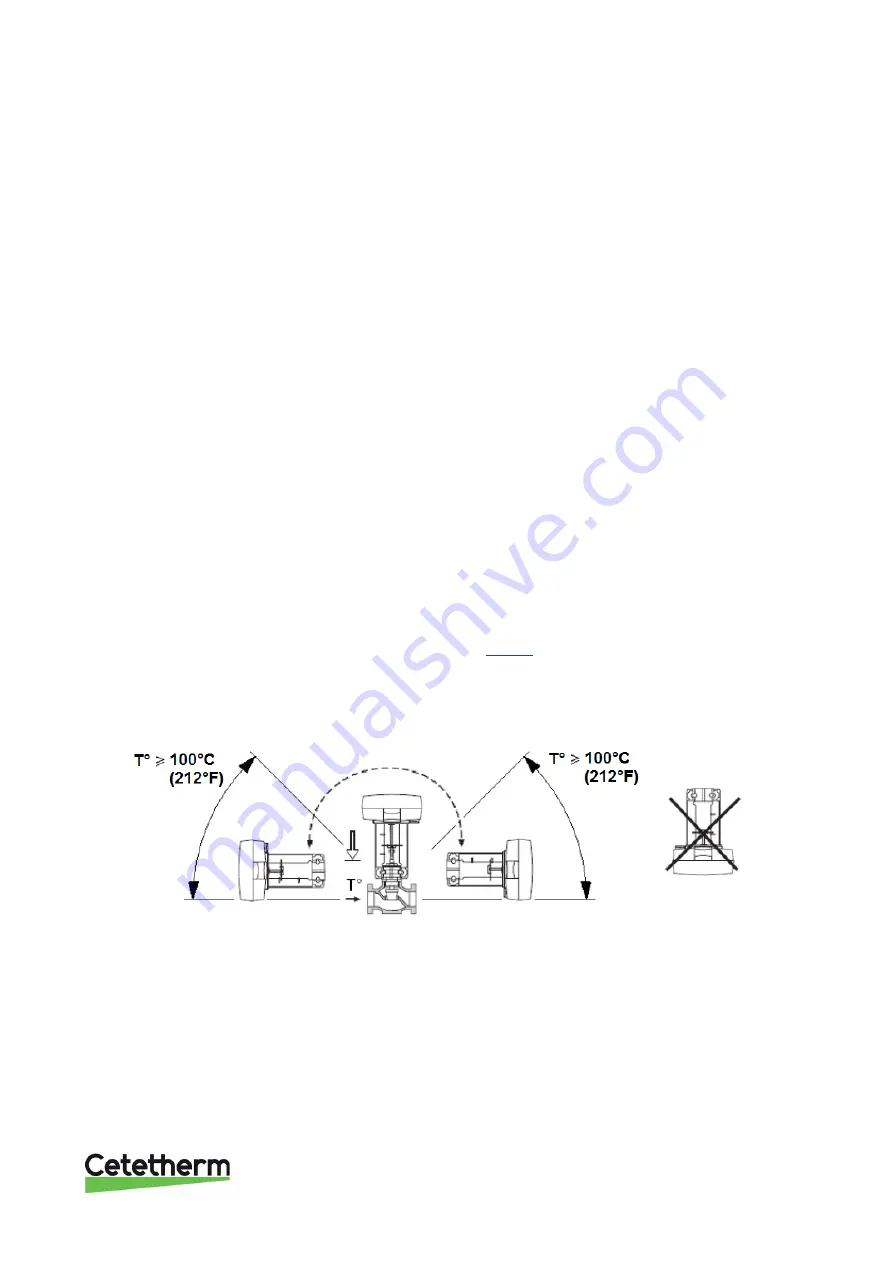

With supply temperatures above 100°, it is recommended that the actuator is tilted or put down.

Picture 4

•

Take rules and instructions regarding hot work into account.

•

Connecting pipes shall be suspended so that their weight does not stress the unit.

•

All connecting pipes within and connecting to the units system shall be insulated according to

standards and regulations.

•

Drainage pipes from safety valves must be taken to a floor gully.

•

Energy meters must be installed at a prepared location, replacing a gauge block, or following the

instructions of the energy supplier.