5

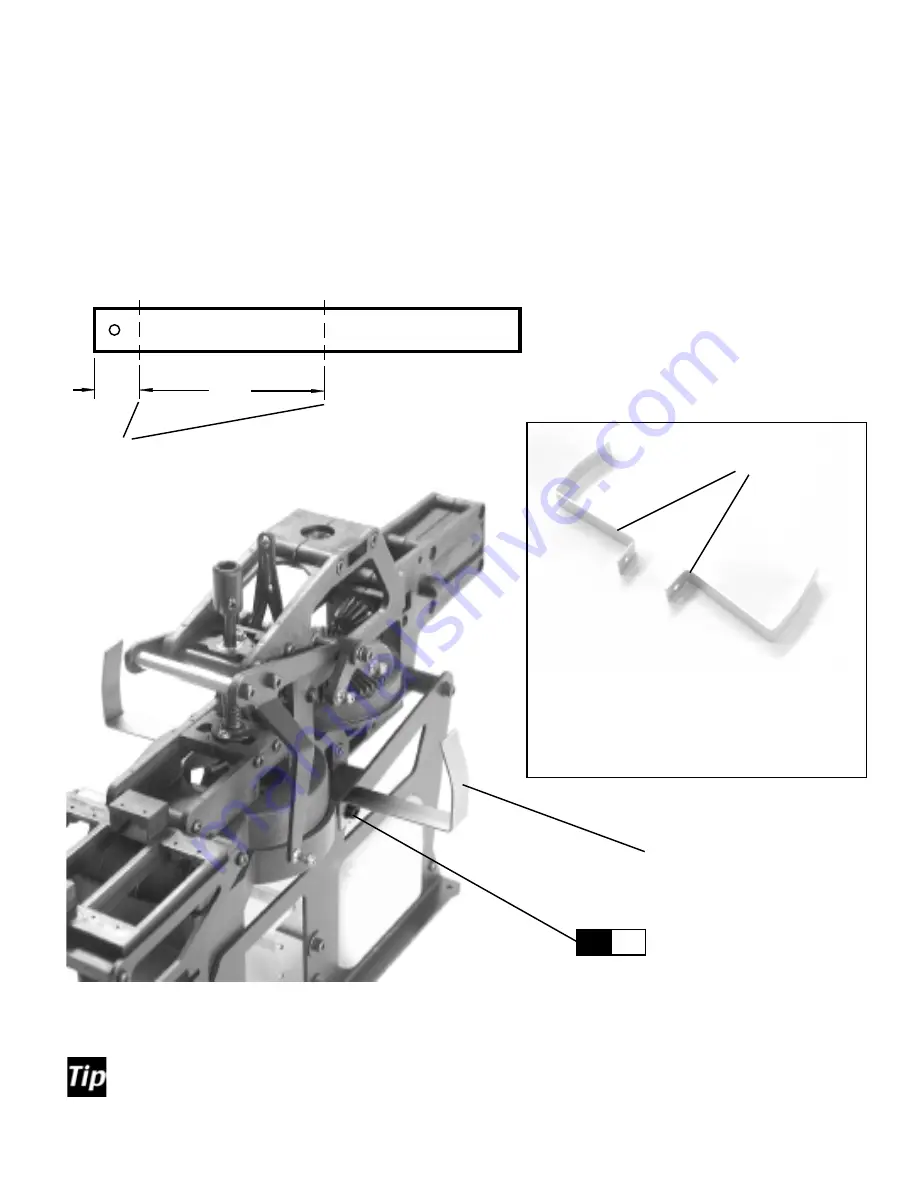

During flight the fuselage will vibrate and depending on the rotor speed, this vibration can be strong enough to

have the some part of the fiberglass contact the mechanics. The common result can range from a mild abrasion to

actual cracking of the fuselage. To eliminate this problem, there are two aluminum strips included with a 3mm

hole pre-drilled in one end. Measuring from the end with the hole, make a mark at 13mm and 63mm where the

strip will be bent to match the photo. Using a set of pliers that have a smooth, straight jaw (or possibly a table vise)

bend the first 13mm mark at 90° degrees downward, bend the second 63mm mark 90° degrees upward. The last

portion of the support should be curved to match the vertical side wall the the fuselage. At a minimum apply vinyl

tape (not included) to the vertical support where it will contact the fuselage, using a thin foam weather-stripping

would be better to dampen all vibration. Attach the support to the forward M3x16 Socket Cap Screw on the lower

side frames. After the mechanics are in the

final position, some slight adjustment is

possible by bending the last segment to fit.

STEP 2 Fuselage Side Supports

STEP 2 Fuselage Side Supports

STEP 2 Fuselage Side Supports

STEP 2 Fuselage Side Supports

STEP 2 Fuselage Side Supports

Final shape of the fuselage supports before

applying tape or weather-stripping. Remem-

ber to thoroughly clean the parts before

applying any adhesive tape.

Fuselage supports

[CN1075-5]

An alternate to using tape is to apply “Goop” or “Zap-a-Dap-a-Doo” type of adhesive to the seams of the

supports, effectively bonding them to the fuselage sides. These types of adhesives can be removed at a

later time by scoring and cutting through the joints. With the mechanics temporarily positioned, mark with

pencil the outline of the support and thoroughly clean the fiberglass surface with rubbing alcohol.

Apply tape, foam

tape or semi-perma-

nently bond in place.

Front M3x16

Socket Cap Screw

2.5

2.5

2.5

2.5

2.5

Hex

Hex

Hex

Hex

Hex

13mm

50mm

Bend at the

dashed lines.

Fuselage supports x 2

Twinstar Detail Manual

Twinstar Detail Manual

Twinstar Detail Manual

Twinstar Detail Manual

Twinstar Detail Manual