26

Section 1 - Outdoor Furnace Installation

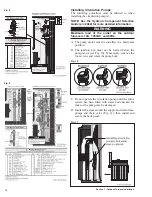

Radiant Floor System Installations

Installing radiant floor heating is a very viable heating

option when either remodeling or building new. Radiant

floor heat can also be added to an existing home easily

if the floor joists are exposed (as in an unfinished

basement). Piping may be installed in a wide variety of

configurations and locations including, but not limited

to, the following:

• In a concrete slab

• Within the subfloor system (e.g., Gyp-Crete®)

• Within the floor joist system

• Within the walls or ceilings

When installing piping between floor joists (16" or 41

cm on center) run two 1/2" pipes between each joist.

Insulate below the piping to prevent excessive heat in

the lower level.

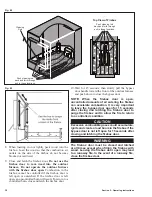

Proper insulation is key to effective radiant heating and

controlling large heat demands. Heat from this type of

system radiates equally in all directions. As an example,

if piping is installed in a slab, the ground below the slab

must be dry and well-insulated. If not properly insulated,

nearly 50% of the heat will be wasted warming the

ground below the slab. Two inches (5 cm) of blueboard

insulation is recommended. Two 1" (2.5 cm) layers of

blueboard can be used. This allows lapping of the joints

in the 4' x 8' (122 x 244 cm) sheets.

NOTE: Do not use beadboard (expanded

polystyrene), bubble foil or roll-out foam insulation.

NOTE: A minimum of one inch (2.5 cm) of

insulation should be used. Two inches (5 cm) of

insulation and vapor barrier below the insulation

is recommended.

Areas with high water tables need to be prepared

properly to prevent contact between the ground water

and insulation.

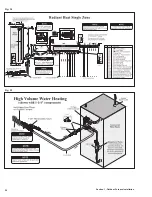

For examples of radiant heating systems using 1/2"

piping in the loops, refer to Fig. 29 through Fig. 32.

The spacing of each circuit is 12" (30.5 cm) between

pipes. The water circulates in opposite directions to

provide an even distribution of heat. The mixing valve

regulates the temperature of the water circulating

through the loops by mixing return water with the hot

supply water. In applications where high heat loss is

expected, loop spacing may be reduced to 10" (25 cm)

or less. If additional information is desired, contact your

dealer.

NOTE: The longer the loop length, the lower the

flow rate and the lower the heating capacity.

Loop lengths greater than 350 feet (107 m) are

not recommended.

NOTE: The temperature of the water used in

radiant heating should be determined by the

installer in accordance with the application.

NOTE: It is not uncommon that it can be very

difficult to get a concrete slab up to temperature

in late fall or early winter in a new building that

is not completely sealed and not well insulated.

Once the building is completely sealed and well

insulated, bringing the slab up to temperature

can still take a considerable amount of time and

wood; however, once warm, wood consumption

will be reduced if the concrete slab and building

are insulated properly .

NOTE: For zone installations, refer to Fig. 30

(multi-zone) or Fig. 32 (single zone).

Insulation

Insulation

Poly Vapor

Barrier

Soil/Sand

Slab

Footing

Ground Level

Plate

Slab on grade

Slab

Wire

Mesh

Insulation

Vapor Barrier

2" Blueboard Styrofoam

®

is recommended (minimum

of 1" Blueboard Styrofoam

®

).

Basement

Insulation

Insulation

Poly Vapor

Barrier

Soil/Sand

Slab

Footing

Ground

Level

Plate

(For Slab on Grade or Basement)

Radiant Floor Heat

Hot Supply Return

© 2013 Central Boiler

NOTE: If the temperature of the

concrete slab is below freezing

(32˚F), there must be adequate

antifreeze in the system, or the

slab must be pre-heated, before

water is circulated through the

radiant slab system.

Fig. 29

Содержание e-Classic 1450 IR

Страница 17: ...15 Section 1 Outdoor Furnace Installation...

Страница 29: ...27 Section 1 Outdoor Furnace Installation Fig 30 Fig 31...

Страница 30: ...28 Section 1 Outdoor Furnace Installation Fig 32 Fig 33...

Страница 66: ...64 E CLASSIC 1450 WIRING DIAGRAM Section 6 General Information...

Страница 67: ...65 Section 6 General Information E CLASSIC 1450 WIRING DIAGRAM OPTIONAL POWER IGNITION...

Страница 69: ...67 NOTES...

Страница 70: ...68 NOTES...

Страница 71: ...69 NOTES...