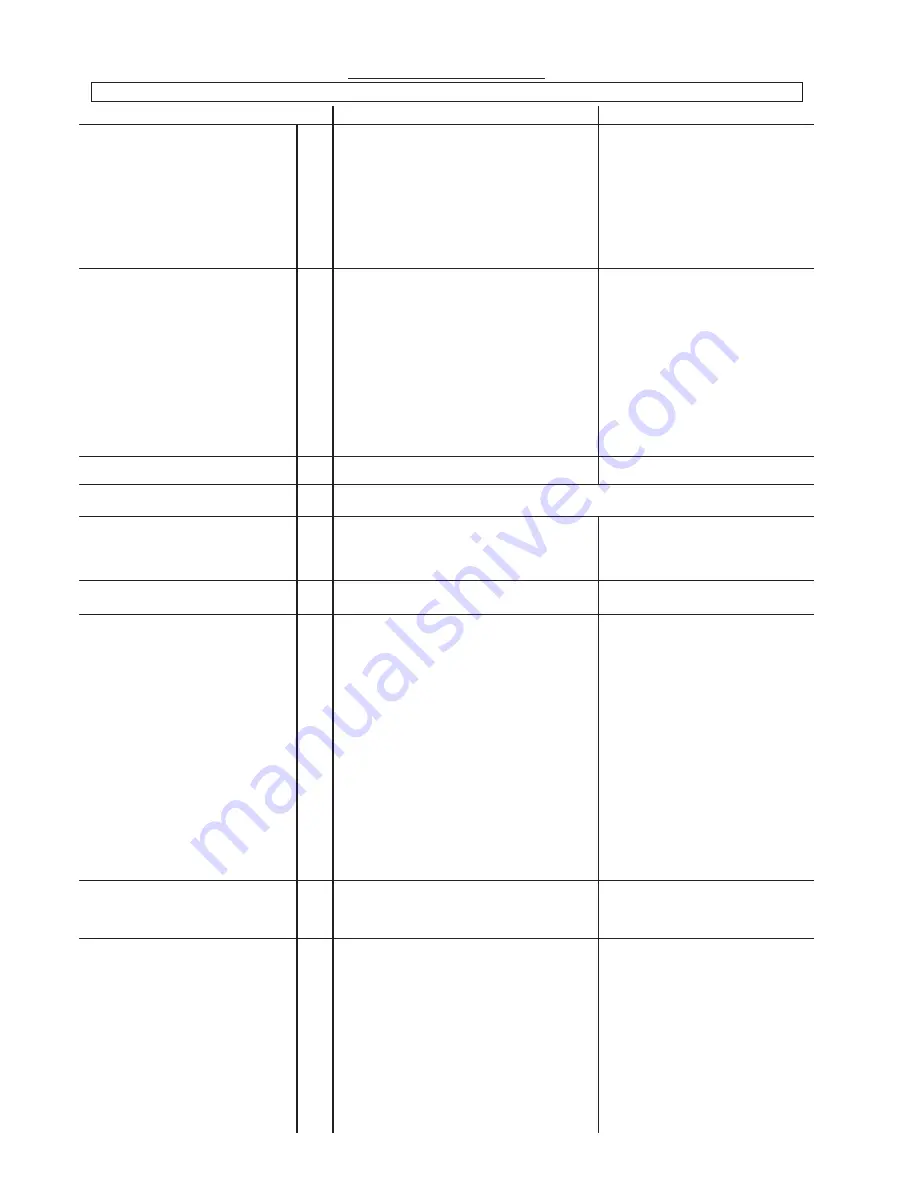

TROUBLESHOOTING

FAULT

POSSIBLE CAUSES

REMEDIES

NO WEDGES ARE INSERTED

INTO THE MOULDING

THE WEDGE IS NOT FULLY

INSERTED INTO THE

MOULDING

THE WEDGE BREAKS

MOULDINGS DIFFICULT

TO MOVE

STAINS ON BACK

POOR JOINING

- Corner open on inside

- Corner open on outside

- Opening on top and bottom

of joint

- Mouldings marked by

triangle rubber top pressor

THE WEDGE DRIVER BLADE

DOES NOT LOWER

- The wedge cartridge is empty

- The wedge distributor is clogged

- The wedge spring is broken or relaxed

- The wedge driver blade is broken

- Top clamp / Moulding distance not

within permissible maximum

- Moulding not adequately secured on the

table

- Wedge driver blade damaged

- Hard wood

ANGLE OFFSET

- The first moulding was not pushed firmly against the left stop (page 5)

- The rebate clamp is too tight against the

mouldings.

- Too much grease on the wedge driver

blade

- Bad cut

- Incorrect setting

- Incorrect setting of stops

- Triangle rubber top pressor for hard

wood used on soft wood

- Misalignment

- Fit a new wedge cartridge

- Clean it

- Check the condition of the spring

and replace if necessary

- Change the wedge driver blade

(page 10)

- Reposition the plunger within

permissible maximum distance

(page 6)

- Secure the moulding firmly on

the table

- Change the wedge driver blade

- Use hard wood wedges (page 7)

- When the rebate clamp is tight-

ened do not push it towards the

mouldings

- Clean the wedge driver blade

- Repeat the cut

- Loosen the AS screw (page 2-4)

to compensate for opening

- Check the self-adjusting

backfences before starting under-

pinning

- Use a suitable triangle rubber top

pressor (page 6)

- Contact after-sales service

IF THE PROPOSED REMEDIES DO NOT SOLVE THE PROBLEM CONTACT THE AFTER-SALES SERVICE

THE PLUNGER DOES NOT

LIFT

- Limit screw incorrectly set

- Check the setting of the limit

screw

- Air supply pressure less than 6 bar

- Increase the pressure

- Wedge jammed in the wedge distributor

- Dismantle the wedge driver blade

to remove the wedge (page 10)

- Limit screw incorrectly set

- Reset the limit screw (page 11)

- Distance between bottom of top clamp

and top of moulding outside permissible

maximum

- Reposition the plunger and expel

any wedge that may have gone

into the wedge distributor using

the tool supplied (page 9)

12

88-89

89

88-89

88-89

88-89

88-89

88-89

88-89

88-89

88-89

88-89

89

88-89

88-89

88-89

88-89

88-89

88-89

88-89

88-89

89

Содержание CS 88

Страница 17: ......