Maintenance, Errors, Repair

REFLECTA/5

Page D1

Mounting & Operations Manual

Content

Maintenance ............................................................................................................................... D1

Lubrication of Compass Suspensions.............................................................................. D1

Compass

Routine Service................................................................................................ D1

Replacing Bulbs ............................................................................................................... D1

Cleaning of Reflection Optics ........................................................................................... D2

Errors, Diagnosis and Help......................................................................................................... D3

Visible

Compass Errors.................................................................................................... D3

Indication Errors ............................................................................................................... D3

Friction Error and Swirl Error Test.................................................................................... D4

Replacement

of compass................................................................................................. D4

Workshop Repair of Compass ................................................................................................... D5

Maintenance

Ensure propper operation of the magnetic compass whenever possible to guarantee safe navigation!

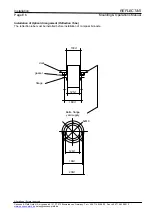

Lubrication of Compass Suspensions

This has to be done from time to time to grant free movement of compass bowl.

Compass Routine Service

A faulty compass function is difficult to detect by onboard means. Therefore a routine service is recommended.

Often certain service intervals are laid down in the national regulations. According to German BSH regulations

an inspection of the compass is necessary every year year for passenger and every five years for freight

vessels. The correct function will be certified by the BSH authorized compass work shop by the official BSH test

certificate. If the compass service was carried out by a foreign and not BSH authorized work shop (because the

vessel has not called a German port) the certificate issued can be sent to the BSH for acceptance.

A preliminary functional test with oboard means is described below in chapter “Friction Error and Swirl Error

Test“. This should be carried out from time to time. A positive result is not be understood as guarantee for a

reliable operation but in case of a negative result the compass should be immediately replaced with the spare

compass, sent to a qualified compass workshop or order replacement compass, see below.

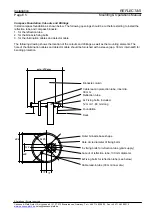

Replacing Bulbs

Use glow lamps of type E14, 40VA (60 VA) with 14 mm screw socket only.

The illumination arrangement is to be found in the upper part of the binnacle column and will be accessible after

removing of hood and compass.

Illumination.

Remove compass for free

access.

Alterations / Errors reserved

Cassens & Plath GmbH, Am Lunedeich 131, 27572 Bremerhaven, Germany, Tel. +49 471 483 999 0, Fax +49 471 483 999 10

www.cassens-plath.de