INTRODUCTION

STC® disassembly action

NOTICE:

Do not use the disconnect tool to pry on the

parts. Prying can result in damage. Insert the tool straight

into the connection. The proper connection and discon-

nection of

STC®

parts is outlined later in this section.

1. Release pressure from the hydraulic system prior to

disconnecting components.

2. Some fluid may still be in the system. Minimize fluid

loss by draining the fluid from system components

prior to disconnection.

3. Prior to disconnection, clean the area around the fit-

tings with a clean cloth, Or using an airgun to blow dirt

and debris from the release sleeve area.

4. To help avoid the release sleeve from tearing, create

an (for the release sleeve) insertion gap by moving the

sleeve in the release direction. This can be done either

by hand or by using a single prong of the release tool.

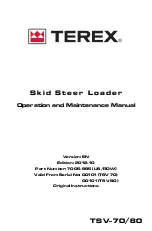

5. As the

STC®

tool

(1)

is inserted behind the release

sleeve

(2)

, the steel insert pushes the latching ring

forward into a groove in the female half I.D., allowing

the two halves to be pulled apart. The thickness of

the tool moves the sleeve forward far enough to make

the disconnection, so prying sideways with the tool is

unnecessary

RAIL17TLB0465AA

10

RAIL17TLB0465AA

11

RAIL17TLB0467AA

12

Seal replacement instructions inspection

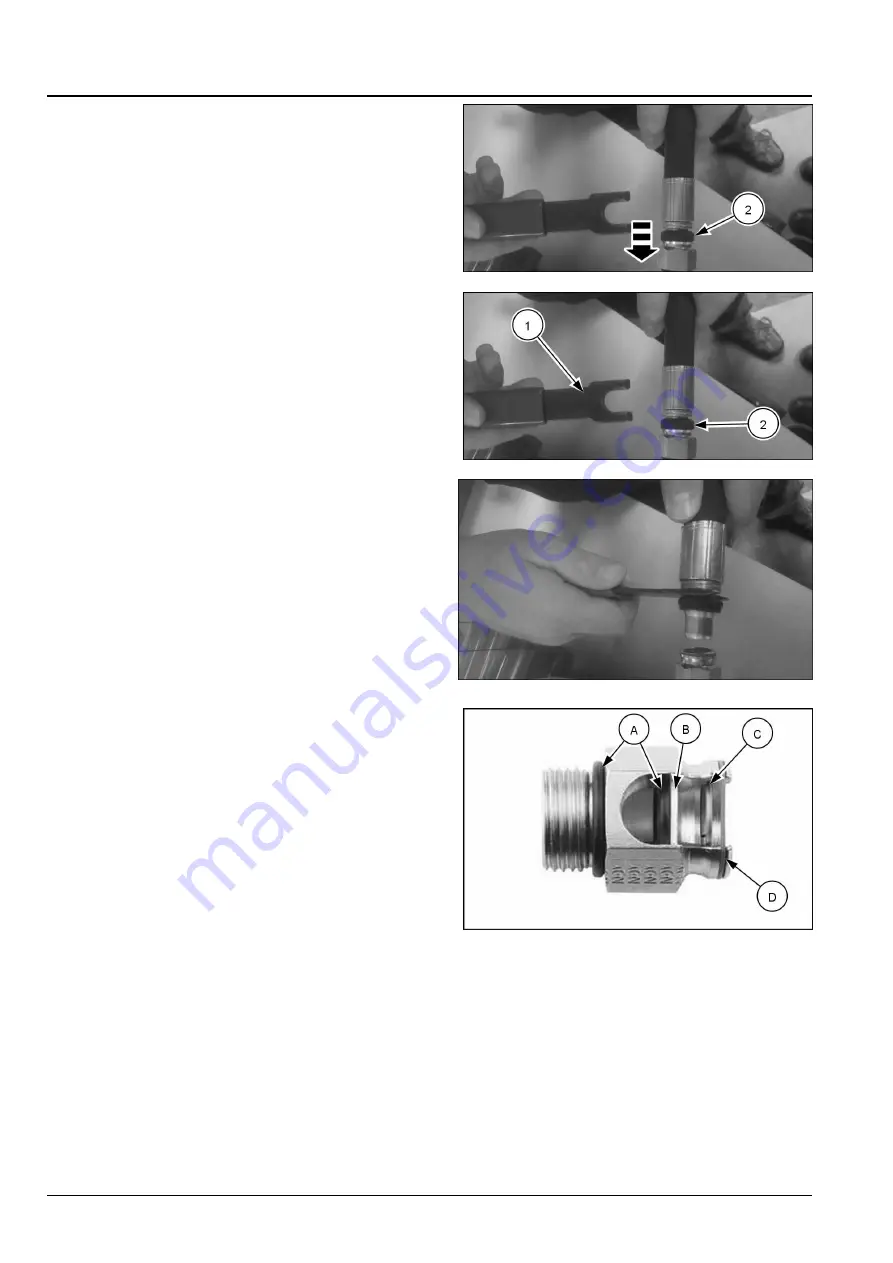

• Inspect mating

STC®

fittings to ensure they are in

good condition, clean and free of contaminants, nicks,

scratches, flat spots, etc.

• Check the Latch Ring

(C)

to ensure that it is in proper

position in the female

STC®

connector prior to installa-

tion or connection.

• Check the O-Ring

(A)

to ensure it is not cut or otherwise

damaged prior to installation or connection.

• Check the Back-Up Ring

(B)

to ensure it is not dam-

aged. Verify that it is at the front of the O-Ring groove

prior to connection the fitting.

RAIL17TLB0016AA

13

• If any damage is detected on either of the O-Ring,

Back-Up Ring or Latch Ring, replace them by following

these procedures:

1. Carefully remove O-Ring

(A)

and Back-Up Ring

(B)

with an O-Ring pick with out damaging the interior

surfaces of the fitting.

2. Inspect the interior surfaces and grooves of the fit-

ting and ensure that they are free of foreign material

or nicks, scratches, dents, etc.

3. If undamaged, clean the fitting and install the

Back-Up Ring

(B)

at the front of the O-Ring groove.

48194558 20/10/2017

66