30

8 - DIAGNOSTICS

The control system has many fault tracing aid functions,

protecting the unit against risks that could result in the failure

of the unit.

The. local. interface. gives. quick. access. to. monitor. all. unit.

operating conditions. If an operating fault is detected, the

alarm is triggered.

8.1 - Control diagnostics

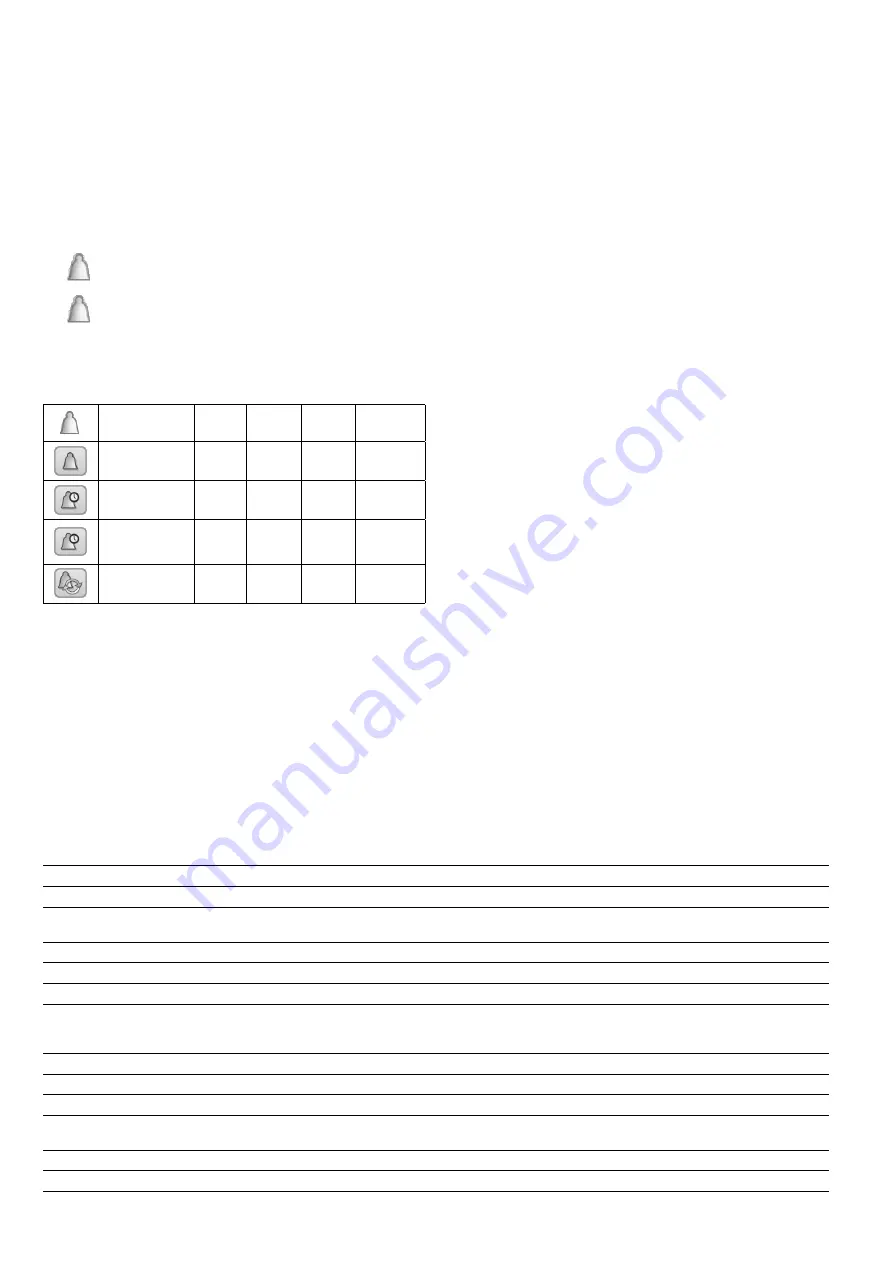

The user interface enables the quick display of the unit status:

The

blinking bell

icon indicates that there is an alarm,

but the

unit is still running

.

The

highlighted bell

icon indicates that the

unit is shut

down

due to a detected fault.

All information regarding the existing alarms (current and

past alarms) can be found in the Alarm menu.

Viewing alarm information

Alarm menu

Date

Hour

Code Description

Current Alarms

(basic access)

•

•

•

Alarm Historic

(basic access)

•

•

•

Major Alarm

Historic

(basic access)

•

•

•

Reset Alarms

(user access)

•

8.2 - E-mail notifications

The. control. provides. the. option. to. define. one. or. two.

recipients.who.receive.e-mail.notifications.each.time.the.new.

alarm.occurs.or.all.existing.alarms.have.been.reset..

IMPORTANT:

E-mail notifications can be configured only

by Carrier service technicians.

8.3 - Displaying current alarms

The Current alarms menu may display up to 10 current alarms.

To access the list of currently active alarms

1. Press the

Alarm

button in the upper-right part of the screen.

2. Select

Current Alarms

.

3..The.list.of.active.alarms.will.be.displayed.

8.4 - Resetting alarms

The alarm can be reset either automatically by the control

or manually through the touch panel display or the web

interface (in the Reset Alarms menu).

• The Reset alarms menu displays up to 5 alarm codes

which.are.currently.active.on.the.unit.

• Alarms can be reset without stopping the machine.

• Only logged-in users can reset the alarms on the unit.

To reset the alarm manually

1. Press the

Alarm

button in the upper-right part of the screen.

2. Select

Reset Alarms

.

3. Set “Alarm Reset” to Yes.

IMPORTANT:

Not all alarms can be reset by the user. Some

alarms are reset automatically when operating conditions

return to normal.

CAUTION:

In the event of a power supply interrupt, the

unit restarts automatically without the need for an external

command. However, any faults active when the supply is

interrupted are saved and may in certain cases prevent a

circuit or a unit from restarting.

8.5 - Alarm history

Information.regarding.resolved.alarms.is.stored.in.the.Alarm.

history.menu.which.is.divided.into.50.recent.alarms.and.50.

recent major alarms. Alarm history can be accessed through

the.Touch.Pilot.user.interface.or.the.Network.Service.Tool.

To access the alarm history

1. Press the

Alarm

button in the upper-right part of the screen.

2. Select

Alarm Historic

or

Major Alarm Historic

.

3. The history of alarms will be displayed.

8.6 - Alarms description

The following table includes a list of alarms that might appear

on the unit.

No. Code

Alarm description

Reset type

Action taken

Possible cause

Thermistor failures

1

15001 Cooler Entering Fluid Thermistor

Automatic, if thermistor

reading returns to normal

Unit shuts down

Defective thermistor

2

15002 Cooler Leaving Fluid Thermistor

As above

Unit shuts down

As above

3

15006 Condenser Entering Fluid Thermistor

As above

Unit shuts down

As above

4

15007 Condenser Leaving Fluid Thermistor

As above

Unit shuts down

As above

5

15011 Master/Slave Common Fluid Thermistor

As above

Master/slave operation is

disabled and the unit returns

to the stand-alone mode

As above

6

15012 Circuit A Suction Gas Thermistor

As above

Circuit A shuts down

As above

7

15013 Circuit B Suction Gas Thermistor

As above

Circuit B shuts down

As above

8

15014 Circuit C Suction Gas Thermistor

Not applicable to this unit

9

15015 Circuit A Discharge Gas Thermistor

Automatic, if thermistor

reading returns to normal

Circuit A shuts down

Defective thermistor

10

15016 Circuit B Discharge Gas Thermistor

As above

Circuit B shuts down

As above

11

15017 Circuit C Discharge Gas Thermistor

Not applicable to this unit