38

ENG

MC DUCT +03U400025 - rel. 4 - 20201201

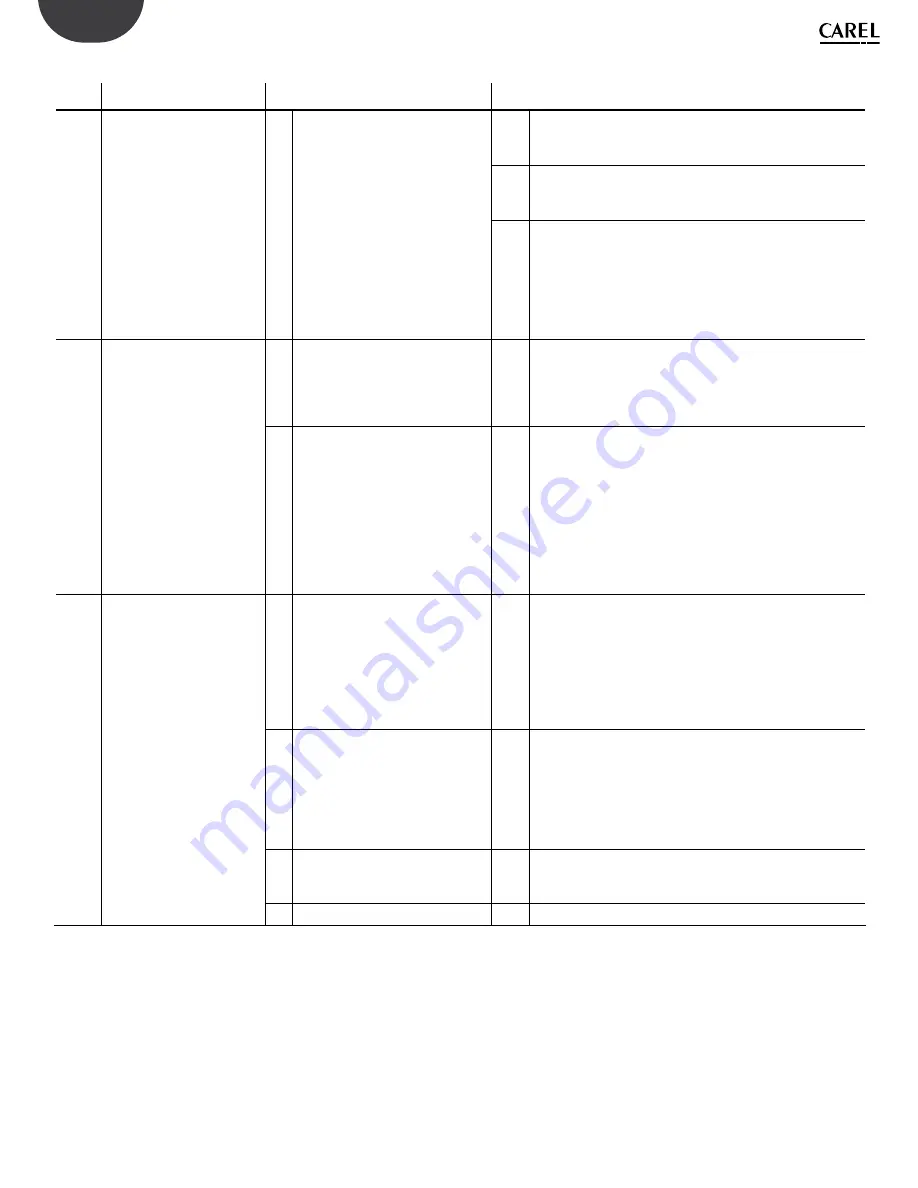

Line

Problem

Cause

Solution

3

Individual heads spray

heavier than the rest.

C1 Valves not fully open or closed

S1

Check that all valves on the heads are either full open or full

closed

S2

Check the air cap and water nozzle orifices for wear or

occlusion. Clean or replace if necessary.

S3

Remove the atomizing heads in question and check the

adjustment of the maximum capacity against a calibrated

water flow meter, one head at a time. If the water flow is

incorrect at the design pressures (30psi air / 5psi water), then

turn the adjusting screw in the back of the head clockwise to

reduce the flow and counter clockwise to increase it.

4

All heads spray too heavy

or too light.

C1 Air stream is already satisfied

S1

Check the condition of the air stream. If you are doing startup

of the unit, and forcing the system to operate at 100% with

little to no actual demand, then the observation of too much

mist may be inaccurate.

C2 Air or water pressure setting

incorrect

S2

With the system at 100% demand (output), adjust the air

and water pressure regulators in the control cabinet to their

proper settings of 30psi air and 5psi water at the end of the

manifolds. Now adjust the water pressure regulator up/down

until an acceptable output is observed. (Warning: Increasing

the water pressure to gain more output may actually result in

less evaporation due to the larger droplet sizes created. You

must confirm the proper pressure settings before calling to

discuss performance issues.)

5

The top of the AHU/duct

is getting wet.

C1 Incorrect Installation

S1

Check that the system is installed as directed by the custom

installation drawings. Confirm that the dimensions used to

create the drawings are the actual dimensions of the AHU.

If the designed clearance to the top of the AHU cannot be

achieved, tilt the atomizing manifold so that the discharge

of the heads is directed toward the top of the cooling coil/

mist eliminator.

C2 Incorrect Installation

S2

Check to see if the AHU is operating with a variable frequency

drive. If so, this information may not have been passed on the

CAREL when the installation design was done.

If the system is a VAV unit, tilt the atomizing manifold so that

the discharge of the heads is directed toward the top of the

cooling coil/mist eliminator.

C3 Obstructions

S3

Check for items that may cause turbulence in the

humidification section, i.e.: face by-pass dampers, air blender,

leading elbows, etc.

Содержание MC

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 46: ...46 ENG MC DUCT 03U400025 rel 4 20201201 ...

Страница 47: ......