11

ENG

“

kit OEM KEC

” +030222160 - rel. 1.0 - 03/11/2015

•

The diameter of the feedwater inlet tubing must be greater than

or equal to the inlet connector on the unit. The material must be

compatible with the feedwater used (stainless steel for demineralised

water).

•

The water inlet lines must be flushed after installation and in any case

before starting the unit the first time.

•

Size the atomisation rack according to the minimum capacity of the

pumping unit used (see Tab.1.a).

•

Ambient operating temperature: 5...40 °C (41...104 °F)

•

Ambient operating humidity: <90% rH non-condensing

•

Index of protection: IP00

2.3 Feedwater characteristics

Feedwater requirements

Type/property

Requirement

Demineralised

ü

Mains

ü

1

Softened

ü

2

Temperature °C (°F)

1 to 40 (33.8 to 104)

4

Pressure MPa (bars)

0.3 to 0.7 (3 to 7)

3

pH

6.5 to 8.5

Total hardness (mg/l CaCO3)

< 160

Conductivity (μS/cm) a 20°C

< 400

Tab. 2.a

1

The use of mains water with a total hardness and conductivity over the

specified limits is allowed, however maintenance will need to be performed

more frequently on the atomisation rack nozzles, heat exchanger (if present)

and/or droplet separator (if present).

2

To reduce aggressiveness of softened water, the minimum total hardness

should be 20 mg/l CaCO

3

.

3

The range indicated in the table refers to the pump off. With the pump

operating, pressure must not fall below 1.8 bars.

4

A water temperature around 40°C does not improve absorption of the

droplets in the air.

2.4 Assembling the distribution rack

See technical l0500074ML.

The drain solenoid valves on the rack

•

should be fitted directly on the atomisation rack (P/N KEROUTV0*0,

purchased separately) if the pumping unit P/N is KEC*****00;

•

or are already fitted on the water circuit if the P/N is KEC*****10. In this

case, the connection tubing between rack and drain solenoid valves

on the pumping unit must meet the requirements for high pressure

tubing described in paragraph 2.2.

2.5 Fastening the electrical system

The KEC controller and inverter must be installed in the air handling unit’s

electrical panel. Table 2.b describes the limit conditions for storage and

operation.

Specification

Value

Ambient operating

temperature °C (°F)

5 to 40 (41 to 104)

Ambient operating

humidity %rH

< 90 non-condensing

Ambient storage temperature °C (°F) -20 to +60 (-4 to +140)

Ambient storage humidity %rH

< 90 non-condensing

Index of protection

IP20

Tab. 2.b

2.5.1

Fastening the KEC controller

This is installed on a DIN rail and occupies 13 modules. Once the controller

has been placed on the DIN rail, press it in lightly: the rear tabs will click

into place, signifying that the controller is correctly mounted. The tabs are

held in the locked position by return springs. To remove the controller,

simply use a screwdriver to release and lift the tabs.

The installation position in the electrical panel must guarantee good

physical separation between the controller and the power components

(solenoids, contactors, actuators, inverter, ...) and the corresponding

connection cables. The ideal situation would be to install the two circuits

in two separate cabinets. Proximity of the two circuits may cause random

failures that are not immediately evident. The structure of the electrical

panel must ensure correct cooling air flow.

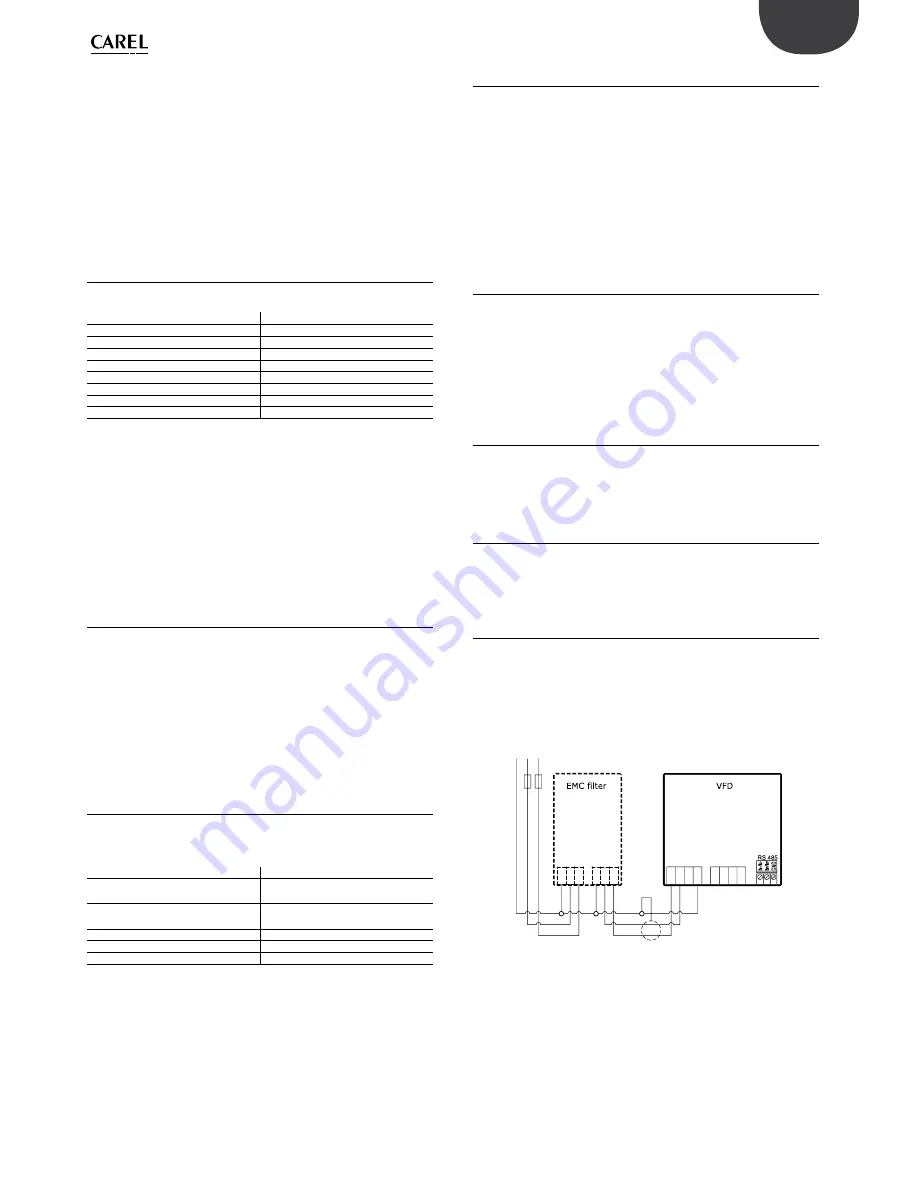

2.5.2

Fastening the inverter

The inverter is secured to the EMC filter using M4 screws; the filter is in

turn screwed onto the electrical panel using M5 screws. Leave clearance

of at least 30 mm on the right and left, and at least 100 mm at the top and

bottom, so as to guarantee sufficient ventilation. The installation position

in the electrical panel must guarantee good physical separation between

the power cable and the serial cable running between the inverter and

KEC controller. Admissible pollution degree is ≤ 2 in accordance with UL

and EN 61439-1.

2.5.3

Fastening the bottom plate (if featured)

If the KEC controller and inverter are supplied already assembled on

the bottom plate, the complete plate then installed inside the electrical

panel.

2.6 Electrical connections

The electrical connections are the responsibility of the OEM, except for

the wiring from the terminal block to the electromechanical components

in the water circuit. The maximum length of the electrical connections

between the electrical components and the water circuit is 15 m.

2.6.1

Inverter power supply

The power supply, to be provided by the user, is:

•

230 Vac single-phase 50/60 Hz + earth for pumps P/Ns KEC***D***;

•

230 Vac single-phase 50/60 Hz + earth for pumps P/Ns KEC***U***.

This is connected to the inverter filter (L, N, PE) and then from there to the

inverter (L1, L2, PE), as shown in Fig. 2.e.

Inverter 230 Vac wiring

L3

L

N

PE

L

N

PE

F1

PE

PE

W

V

U

L2

L1

F2

PE N L

Fig. 2.e