16

Value

Torque at

Torque at

slow speed top speed

1

25%

75%

2

25%

100%

3

36%

75%

Value

Torque at

Torque at

slow speed top speed

4

36%

100%

5

60%

75%

6

60%

100%

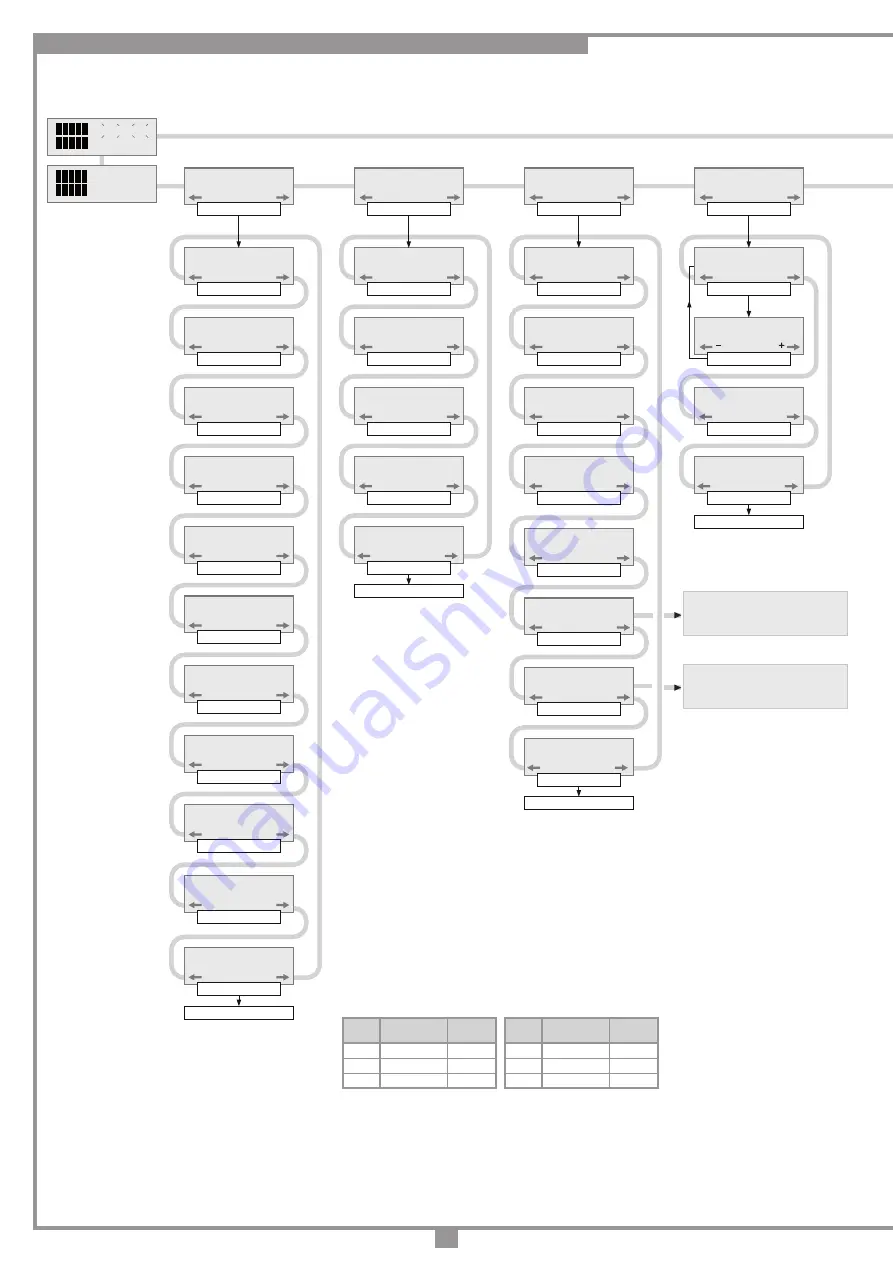

Press the arrows to increase or

reduce the value (max 240 seconds).

Keep the arrow keys pressed to scroll

the value rapidly.

Press OK to reset the parameters to the

factory default settings (excluding the

number of manouvres). Press EXIT

to quit without modifying the parameters

“PROG/OK” to confirm

BACK TO MOTION MENU

EXIT

OK

“PROG/OK” to set

RESET PARAMETERS

OK

“PROG/OK” to set

DIST. FROM OPEN

(6)

0...9 steps

“PROG/OK” to set

DIST. FROM CLOSE

(6)

0...9 steps

SEQUENTIAL COM.

OPEN-SHUT/

OPEN-STOP-SHUT

“PROG/OK” to set

AUTO-RECLOSING

ON/OFF

“PROG/OK” to set

“PROG/OK” to set

WARNING LIGHTS

FIXED/

INTERMITTENT

“PROG/OK” to set

INDICATOR LIGHT

(1)

FIXED/

INTERMITTENT

“PROG/OK” to set

PHOTOCELL INVERT

(2)

DURING CLOSING/

AND IN STOP

“PROG/OK” to set

“PROG/OK” to set

“PROG/OK” to set

INSTALLED MOTOR

LEFT/RIGHT

“PROG/OK” to set

“PROG/OK” to set

“PROG/OK” to confirm

BACK TO OPTIONS

PRE-FLASHING

ON/OFF

TEST FI

(3)

ON/OFF

TEST FS

(3)

ON/OFF

MEMO RADIO

ON/OFF

EXIT

OK

“PROG/OK” to set

FI CONTACT

NC/8K2

TB CONTACT

NC/8K2

“PROG/OK” to set

“PROG/OK” to set

“PROG/OK” to set

“PROG/OK” to confirm

BACK TO SAFETY DEVICES

FS CONTACT

NC/8K2

CP CONTACT

NC/8K2

EXIT

OK

“PROG/OK” to set

CURRENT SENSOR

(5)

LEVELS 1...5

“PROG/OK” to set

“PROG/OK” to set

LIMITED OPENING

1...9 meters

“PROG/OK” to set

ADJUST CONTRAST

0...63

CONTRAST

OK

“PROG/OK” to confirm

“PROG/OK” to confirm

SAFETY DEVICES

OK

“PROG/OK” to confirm

CANCELLATION

OK

MEMORISE

OK

“PROG/OK” to confirm

“PROG/OK” to confirm

“PROG/OK” to confirm

“PROG/OK” to confirm

BACK TO RADIO CODES MENU

CLEAR ALL MEMORY

OK

CHANNEL FUNCTION

OK

EXIT

OK

“PROG/OK” to confirm

REMOTE

OK

OPTIONS

OK

“PROG/OK” to confirm

MOTION

OK

PRESS ANY KEY

BACK TO TEST MENU

“PROG/OK” to confirm

TEST

OK

“PROG/OK” to confirm

DISPLAY

OK

“PROG/OK” to confirm

“PROG/OK” to set

“PROG/OK” to confirm

BACK TO DISPLAY MENU

EXIT

OK

REAR LIGHTING

ALWAYS ON/

60 SEC./30 SEC.

TORQUE SELECTION

(4)

LEVELS 1...6

PROGRAM

T B

F S

F I

CP

00.000.001

T B

F S

F I

CP

TEST

T B

F S

F I

CP

PRESS the

transmitter

channel to be

memorised

CANCELLING.....

MEMORISE [nr ...]

Activation 1

PRESS the

transmitter

channel to be

memorised

MEMORISE [nr ...]

Activation 2

MEMORISE [nr ...]

CODE MEMORISED

“PROG/OK” to confIrm

CLEAR ALL MEMORY?

OK

PRESS the

transmitter

channel to be

cancelled

CANCEL [nr ...]

Activation 1

PRESS the

transmitter

channel to be

cancelled

CANCEL [nr ...]

Activation 2

CANCEL [nr ...]

CODE CANCELLED

Exit

“PROG/OK” to set

CHANNEL A

COMMAND TD/TAL/TA/TC/

STOP/NO COMMAND

CHANNEL B

COMMAND TD/TAL/TA/TC/

STOP/ NO COMMAND

“PROG/OK” to set

“PROG/OK” to set

CHANNEL C

COMMAND TD/TAL/TA/TC/

STOP/ NO COMMAND

“PROG/OK” to set

CHANNEL D

COMMAND TD/TAL/TA/TC/

STOP/ NO COMMAND

“PROG/OK” to set

BACK TO CHANNEL FUNCTION MENU

EXIT

OK

OUT OF POS

T B

F S

F I

CP

STOP PROG

T B

F S

F I

CP

PROGRAM

T B

F S

F I

CP

Flashing on the display. You have to enter the programming mode to program the system.

During normal operation it indicates that the "automatic repositioning" procedure is about to take place. In

this case any commands received (TA, TC, TAL or TD) will automatically start this procedure.

This happens when an N.C. contact is activated (FI, FS, CP) during encoder programming or automatic

repositioning. Once the passive state of the security devices has been reset the gate will start moving

again automatically. It also happens if a blackout occurs during programming.

Safety device test error. Check the condition of the safety devices and make sure that the alarm cuts in

when an obstacle interferes with the beam (the relative LED will switch off). In case of anomalies replace

the damaged safety device or bridge the contact and deactivate the safety test (option menu).

This occurs when the programmer sends a command to the motor and nothing happens (the motor

doesn't move). Check the motor faston connections and the condition of the fuses "F2", "F3" and then

give another opening or closing command. If the motor still doesn't move you are faced with either a

mechanical problem or a problem with the programmer.

If this error occurs during normal motor operation it means that there is a problem with one of the encoder

signals. Check the relative connections and carry out automatic repositioning.

The gate movement direction is different from the encoder setting (eg. the gate moves in the closing

direction while the program is carrying out the opening stage). Check the motor power supply

connections.

Current sensor error. When the gate is not moving this symbol means there is a problem with the current

sensor.

When the safety edge intervenes the gate will automatically invert for 5 cm, both in the closing as well as

the opening direction, to free the obstacle it will then stop for 3 minutes and then continue moving in the

original direction after a 10 second preflashing period has elapsed.

When the sensor intervenes the gate will automatically invert for 5 cm, both in the closing as well as the

opening direction, to free the obstacle it will then stop for 3 minutes and then continue moving in the

original direction after a 10 second preflashing period has elapsed.

SAFETY ERR

T B

F S

F I

CP

ERROR MOT1

T B

F S

F I

CP

ERROR ENC1

T B

F S

F I

CP

ERROR DIR1

T B

F S

F I

CP

ERR. SENS1

T B

F S

I

CP

ACT. EDGE

T B

F S

I

CP

ACT. SENS

T B

F S

I

CP

Alarm indications

AUTO PROG

T B

F S

F I

CP

OPENING

T B

F S

F I

CP

PAUSE

T B

F S

F I

CP

Pause time programming or

pause for automatic reclosing

(if activated)

Automatic programming under

way

Opening stage

Block during opening

Closing stage

Block during closing

Current sensor updating (only

during programming)

Test mode

Battery mode with a fully

charged battery

Battery mode with a

discharged battery. The motor

and commands will be

blocked.

STOP OPEN

T B

F S

F I

CP

UPDAT.SNS1

T B

F S

F I

CP

TEST

T B

F S

I

CP

BATT.

[99%]

T B

F S

I

CP

Operational indications

CLOSING

T B

F S

F I

CP

STOP CLOSE

T B

F S

F I

CP

BATT.

[0%]

T B

F S

I

CP

AUTO PROG

F

F

F

F

F

F

“PROG/OK” to set

PAUSE TIME: 30

OK

FW_0.11

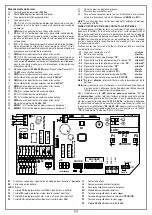

5) Current sensor settings:

-

Level 1

= motor electrical input +

2

amps

-

Level 2

= motor electrical input +

2.5

amps

-

Level 3

= motor electrical input +

3

amps

-

Level 4

= motor electrical input +

4

amps

-

Level 5

= motor electrical input +

5

amps

The programmer checks the electrical input to the motor, detecting any eventual increase in effort above the normal operating limits and intervenes as an

additional safety device.

6) Setting the distance from the closing/opening travel limit:

To increase or reduce this distance modify the parameter in steps from 0 to 9 (range fro 0 to 6 cm ~). By default the appliance is set to level 4 and in this

way the gate will not slam against the travel limits but will stop within a centimetre of them.

PROGRAMMING PROCEDURE (parameter setting)

• All the functions of the electronic programmer can be set in the Display menu "

LCD1

" using the three buttons contained therein:

- use the arrows to navigate through the menu and/or to adjust the display contrast;

- use

"PROG/OK"

to modify the parameter settings and/or to confirm.

Note

:

1) The indicator light flashes slowly during opening, rapidly during closing; remains lit when

the gate is blocked but not completely closed and is off when the gate is completely closed.

2)

FI

Mode:

-

FI

also active when the gate is blocked: If the photocells are in alarm and the gate is blocked, no

movement commands will be accepted (even opening commands);

-

FI

active only during closing

In both cases activating the

FI

safety device during the closing stage will force travel direction

inversion.

3) Photocell test (

FI/FS

)

If you enable the security test you will have to connect both the transmitter and the receiver to the

controlled load output (

CTRL 24 Vdc

). When the test is enabled one second will pass between

receiving a command and carrying it out.

4)

Содержание 105/SLi824

Страница 12: ...12 NOTES ...

Страница 20: ...20 NOTES ...

Страница 28: ...28 NOTES ...

Страница 36: ...36 NOTES ...