CWF, BWF, RWF

Thermocouple Replacement

Disconnect the furnace from the supply, and remove the furnace back panel.

Make a note of the thermocouple connections.

The negative leg of the thermocouple is marked

blue.

Compensating cable colour codings are:

Negative

positive (type K)

positive (type R)

White

green

orange

Disconnect the thermocouple from its terminal block.

Bend the metal tag to release the thermocouple sheath, withdraw the sheath, and shake out any

fragments of thermocouple.

Re-assemble with a new thermocouple observing the colour coding, ensuring that the

thermocouple is not twisted as it is being inserted and that the metal tag is bent back to grip the

sheath.

5.6 Panel Element Replacement (CWF & BWF)

See section 5.2 - wearing a face mask is recommended.

The chambers have two side-mounted refractory panels in which coiled heating elements are

inserted, and one unheated hearth slab.

Disconnect the furnace from the supply and remove the furnace back panel.

Make a written plan showing ALL the element and thermocouple connections. It is important to

make this plan for each individual furnace.

Disconnect all the element wire tails and thermocouple cables from their terminal blocks.

Straighten all the element tails. Note that these become brittle with use.

Unscrew the screws fixing the metal back piece from the inner chamber and withdraw this part

backwards complete with thermocouple(s) and sheath(s).

Withdraw the back insulation piece. Handle with care. Observe the warning on handling of

ceramic fibrous insulation - section 5.2.

Withdraw the old element(s), and insert the new. Note that in the 23 litre models the ceramic

element carriers are in two parts: handle with care.

Replace the back insulation piece and metal piece together with the thermocouple(s) and

sheath(s).

As necessary, shorten the element tails by clipping to length. Remake all the thermocouple and

element connections according to the individual plan.

Refit the back panel and run the furnace for 30 minutes at 800°C without interruption to ensure

complete burn-off of any organic binders. Some smoke may be observed during this process,

which should be carried out in a well ventilated area.

Check that the furnace is controlling properly to rule out the possibility that previous element

failed because of a fault elsewhere in the control circuit.

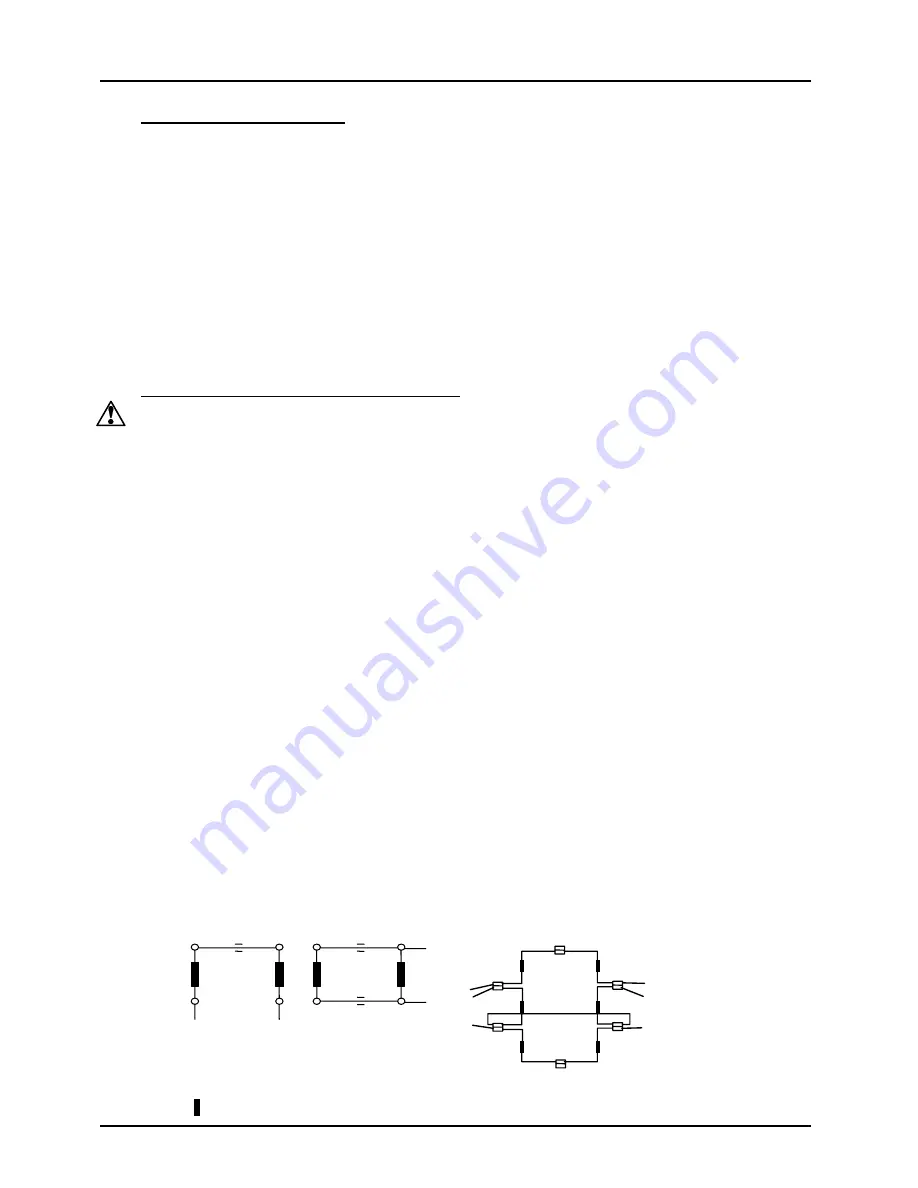

220-240V

200-210V

110-120V

100V

L

N

L

N

5 &13 litre models

= element

Example Connections

N

CWF /23 element connection example

(1-phase 200-240V)

L

N

L

L

N

link

terminal block

MF02

9