1

1

1-7

1-7

Initial Setup > Basic Operation > Maintenance Log List Screen in Operator Maintenance Mode > Control Keys

Initial Setup > Basic Operation > Maintenance Log List Screen in Operator Maintenance Mode > Control Keys

Maintenance Log List Screen in Operator Maintenance

Mode

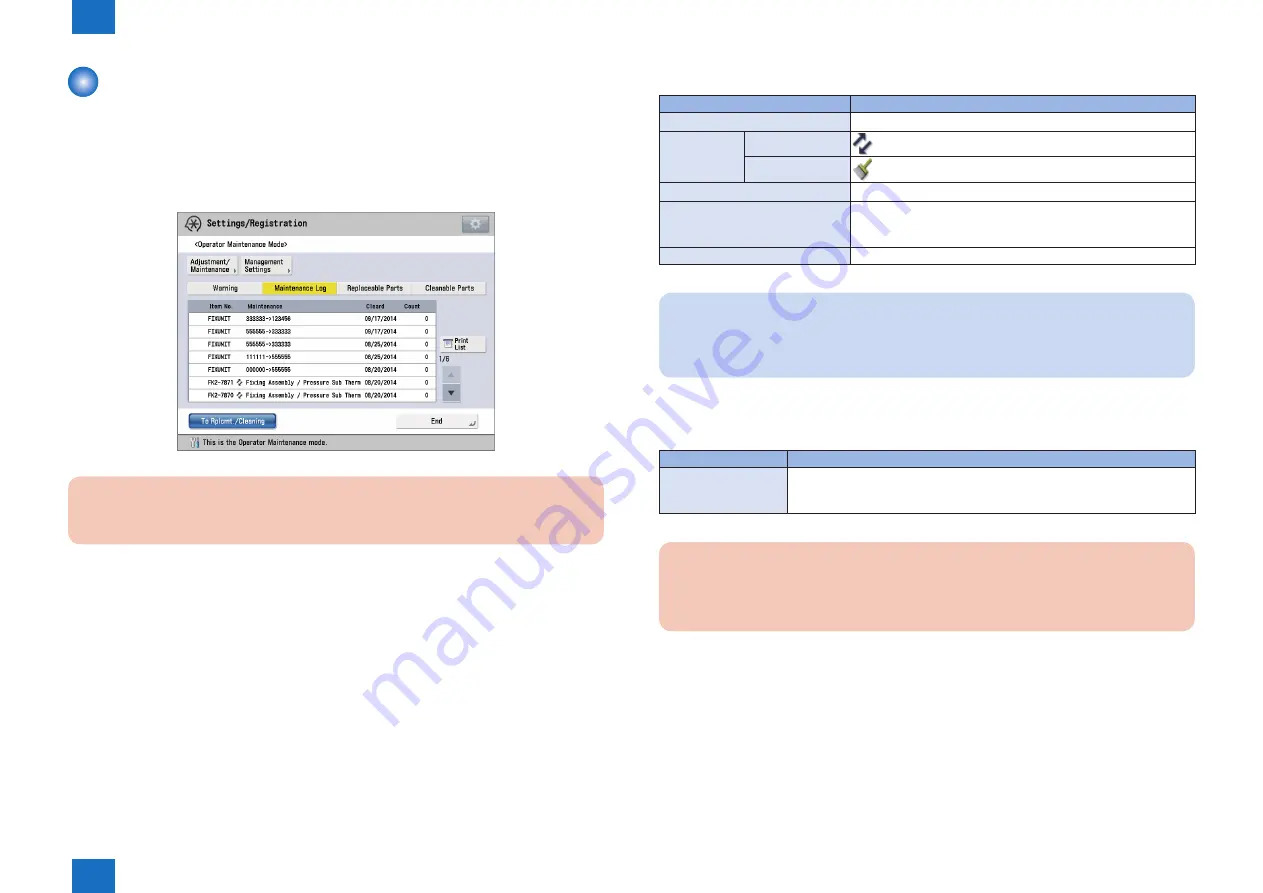

Press [Maintenance Log] in operator maintenance basic screen to show the maintenance log

list.

In the maintenance log list, the maintenance works in replacing/cleaning parts are listed. A

blank list is shown when no history found.

CAUTION:

This is the screen when [Maintenance Log] is pressed.

F-1-11

■

Display

Items

Contents

Item No.

8 digits in characters and numbers (format XXX-XXXX)

Replacement/

Cleaning Icons

Replacement icon

Cleaning icon

Maintenance

Max. 34 single byte characters (overflow will be rounded)

Date of Counter Cleared

Year / Month / Day (For Japan)

Month / Day / Year (For U.S.A.)

Day / Month / Year (For Europe)

Count

8 digit numbers (the count when cleared)

NOTE:

The maintenance history for all replacement parts is shown in the maintenance log list

regardless of the display/non-display setting.

"NOTE: Setting of the parts shown in the lists"(page 1-5).

■

Control Keys

Names of Key

Function

Print List

Press [Print List] to print the maintenance log report.

This key is disabled (shaded) when A4 or larger size paper is not loaded or

it is in Replacement/Cleaning mode.

CAUTION:

If [To Rplcmt./Cleaning] is pressed immediately after pressing [Print List], wait time of

approx. 2 minutes is required in order to protect the device.

T-1-5

T-1-6