CHAPTER 5 TROUBLESHOOTING

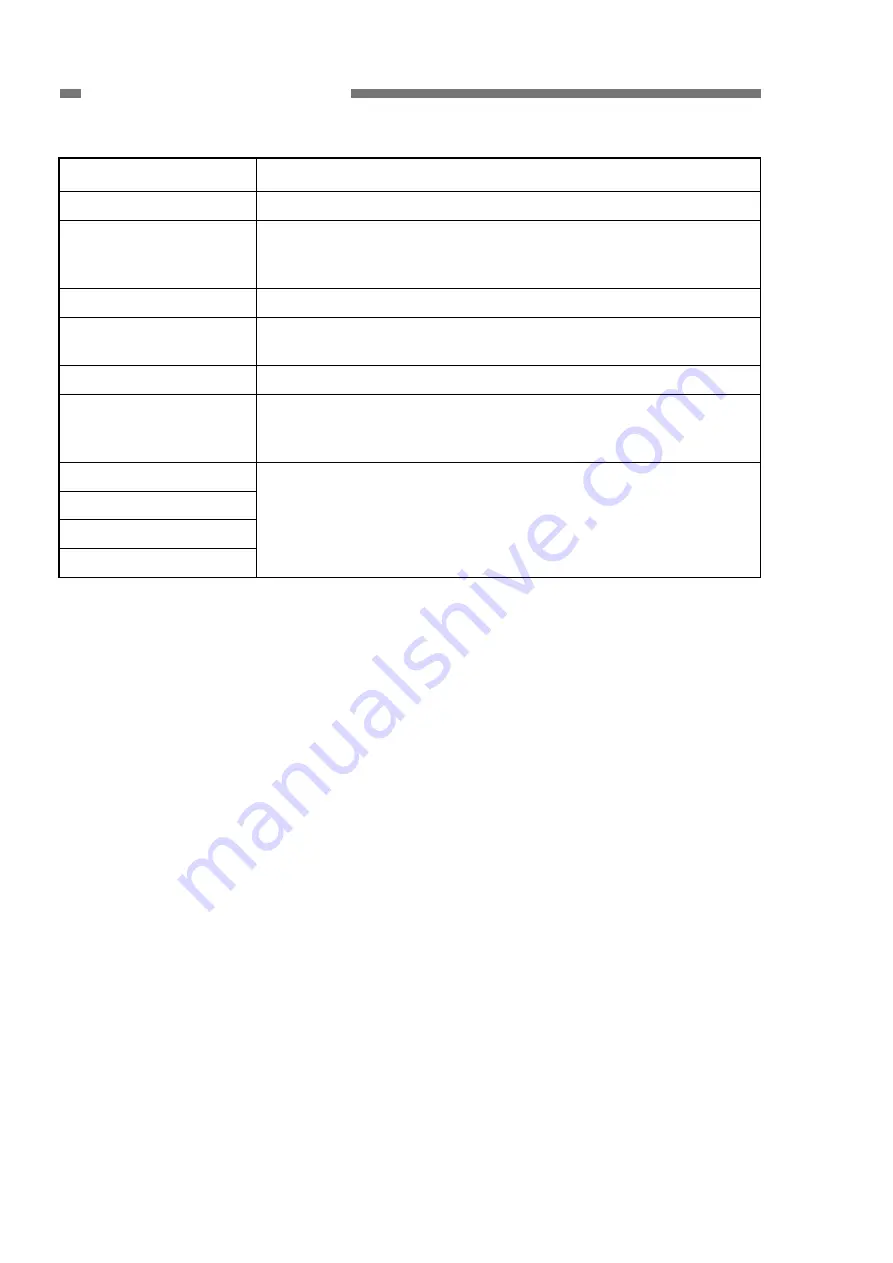

Display Details

Total Count

Total number of sheets that have been fed.

LED Count

Total amount of time that the LED used by the reading unit (upper

and lower) has been alight. Note that the units are in “seconds”.

1000 hours = 3,600,000 seconds.

Jam Count (P01)

The number of paper jams in the pickup section. Error code P001.

Jam Count (P02)

The number of paper jams in the registration section. Error code

P002/006/007.

Jam Count (P03)

The number of paper jams in the eject section. Error code P004.

Replaced Count (Unit1)

Number of feeds when replacing the user replaceable parts (rough

guide to replacement of 200,000 sheets). This displays the total

number of sheets fed when reset in user mode.

Replaced Count (Unit2)

Replaced Count (Unit3)

Replaced Count (Unit4)

Replaced Count (Unit5)

Replaced Count (Unit2) to Replaced Count (Unit5) are used by the

service technicians to manually input the total number of sheets

fed when replacing a part to serve as a rough guide until the next

replacement. The corresponding parts can be decided within each

local region or by the service technicians as necessary.

Table 5-202

After changing the value, select the [Set]

button or [All Set] button at the right side of

each item to apply the changed value.

To close the screen, select [Close].

These values are changed when the

control PCB is replaced. After the replacing

the control PCB, the values need to be input.

If you don't know the values before

replacement, you can input estimated

values.

If you replace the control PCB or change

the [Total Count], then the counter for

[Current Rollers] on the user maintenance

screen is also updated. Since the [Replace

Rollers] message may be displayed the next

time the user turns the power on or the

counter for the [Current Rollers] may take on

an invalid value, you should check the

counter for the [Current Rollers] after exiting

service mode and reset it if it is invalid.

Note:

The count for the current rollers is the

value that subtracted the total sheet

fed count at the last reset from the

current total sheet fed count.

5-14

COPYRIGHT

©

CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

Содержание imageFORMULA DR-M140

Страница 1: ...FIRST EDITION AUG 2011 MY8 13AR 000 COPYRIGHT CANON ELECTRONICS INC 2011 CANON DR M140 FIRST EDITION...

Страница 6: ......

Страница 8: ......

Страница 20: ......

Страница 42: ......

Страница 60: ......

Страница 70: ......

Страница 118: ......

Страница 120: ......

Страница 122: ......

Страница 124: ......

Страница 126: ...0811SZ...