8224 2462-001

31

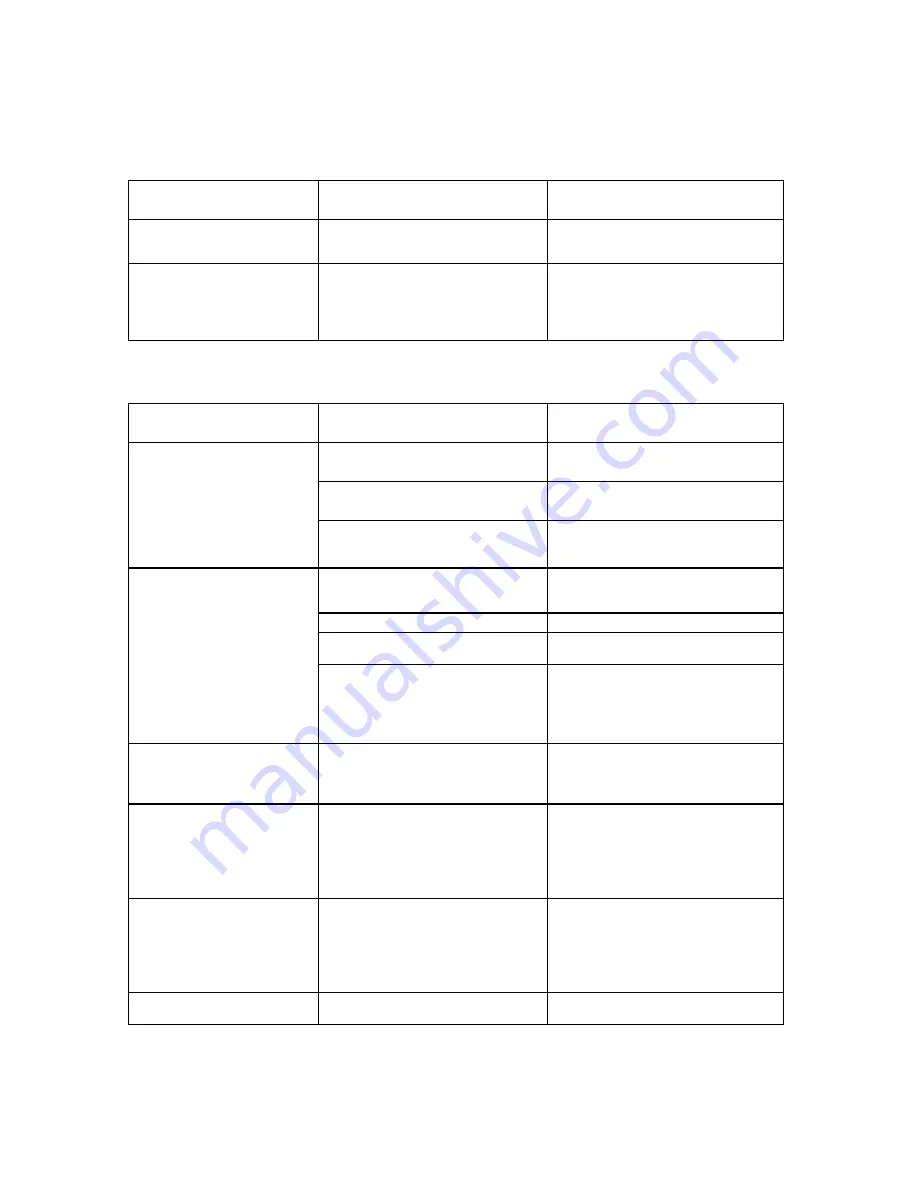

Jams or Unexpected Paper Stops

Symptom

Possible Cause

Solution

Paper does not feed

correctly.

Multiple causes.

See “Feeder”.

Papers stops suddenly and

has leading edge damage.

Debris/obstruction in paper path.

Examine paper path to locate small

bits of paper, tape, staples, etc.

Remove debris gently

Feeder

Symptom

Possible Cause

Solution

Paper does not feed when

the Feed button is pressed.

Feed button is already pressed

down?

Press/tap Feed button momentarily

to start feeding paper.

Scanning(Red LED is always on)

Wait for scanning to finish.

When the Feed button is pressed,

there is no sound from the paper

path.

If problem exists after using another

application such as Checkscan, the

unit requires repair.

Items do not feed when

inserted.

Paper is not covering the feeder

sensor

Insert the paper until the feeder

sensor is covered.

Dirty feeder sensor.

Clean sensor

Scanning software/application not

running

Run scanning software/application

The

motor

runs

but

the

unit/timing/drive belt does not

move.

Examine paper path to ensure the

belt has not come off of a roller or is

not jammed by debris. Return for

service if belt is broken or can not be

moved by hand.

Papers skew as they are

fed.

Inadequate

paper

preparation

before feeding paper.

Ensure the paper is loaded correctly

into the feeder bay.

The floor extender is not installed

correctly.

See Section 1 to correctly install

floor extender. Ensure extender

tab is pushed down into slot on the

unit as far as possible. The

extender floor must be even with the

floor of the feeder bay.

Incorrect

document

position/

insertion for manual feed.

When

manually

inserting

documents, the entire bottom edge

of the document must be in contact

with the floor of the track while you

push the document forward into the

unit.

Unit attempts to scan without

paper

Dirty feeder sensor.

Clean the feeder sensor

Содержание SmartSource Edge

Страница 4: ...8224 2462 001 4 Reader 32 Image 33 Parts 33...

Страница 6: ...8224 2462 001 6 Unpack the Box Like This...

Страница 7: ...8224 2462 001 7 Box Contents...

Страница 8: ...8224 2462 001 8 SmartSource Edge Need Help Burroughs Help Desk 1 800 328 0440...

Страница 11: ...8224 2462 001 11 Step2 Step3...

Страница 13: ...8224 2462 001 13 Section 2 Operating the Unit Power On and Off...

Страница 20: ...8224 2462 001 20 Section 3 Cleaning the Unit WARNING Perform the following steps before cleaning the unit...

Страница 23: ...8224 2462 001 23 Remove Front Removable Image Camera Wall Remove Rear Removable Image Camera Wall...