37

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

pellet feed. We recommend the setting to

be

35%

of the main mode. You can change

the pellet feed quantity

(Feed)

in

%

of the

set value at maximum power, and the

power of both fans: the burner fan

(FanB)

and the exhaust gas fan

(FanE)

.

Select the desired option using the

navigation arrows. Use the „

Enter

” button

to open the next parameter.

Auto Clean Setup

12:00

18:00

00:00

06:00

06:00

21:00

Use this menu to adjust

the automatic cleaning

of burner and boiler

Set the time and the

number of automaticsystem cleaning

(Clean Count). At least one cleaning per

24-hour period is required.

Maximum cleanings - not more than six

times per 24-hour period.

Select the desired option using the

navigation arrows. Use the „

Enter

” button

to open the next parameter.

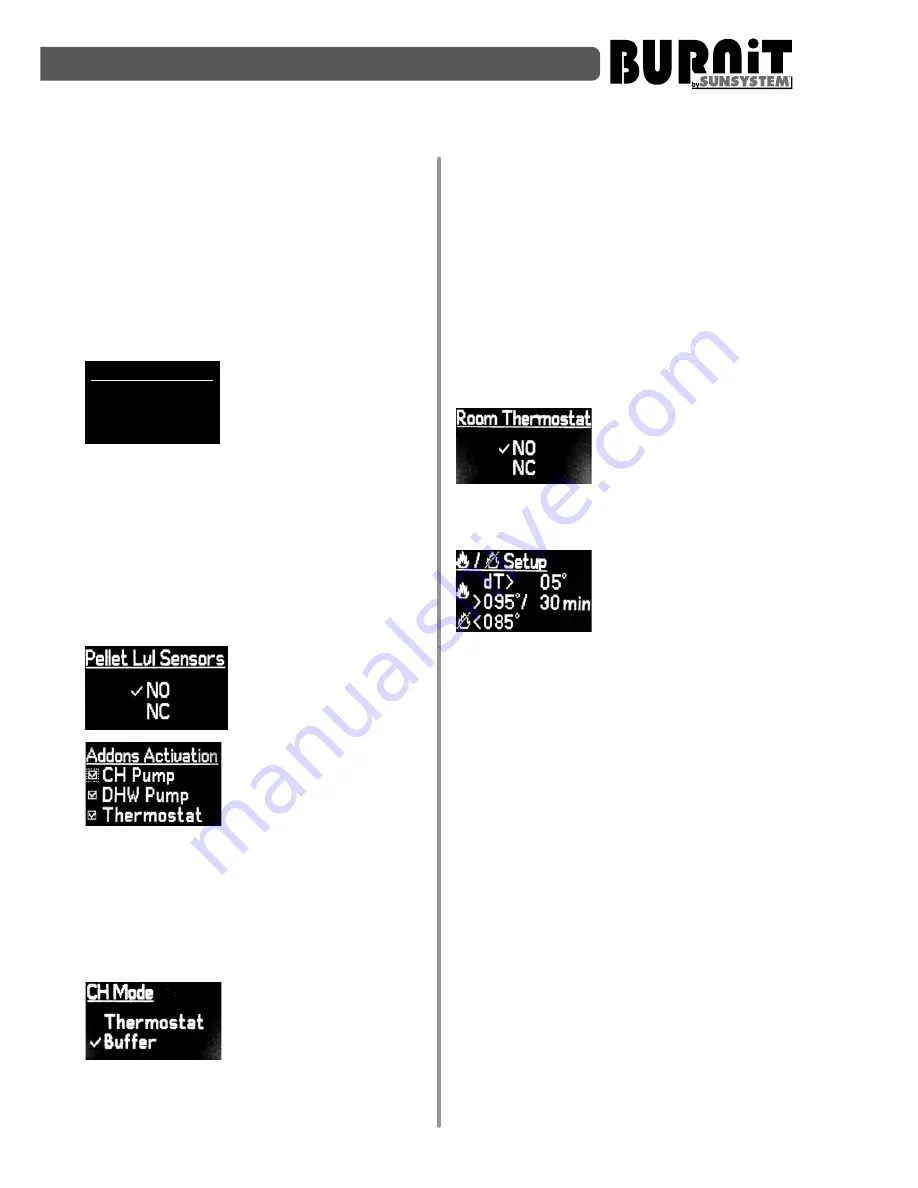

This menu is not active

at the moment.

Does not affect the

boiler operation.

Use this submenu to

activate (with check

mark) or deactivate

additional peripherals.

CH PUMP

– central heating pump

DHW PUMP

– domestic hot water pump

Thermostat

.

Select the desired option using the

navigation arrows. Use the „

Enter

” button

to open the next parameter.

From this screen menu

you can choose the

boiler

operation

management

mode.

This menu is valid only

in the event of "CH only" option selected.

By selecting the checkmark "Buffer" the

boiler will be controlled according to

temperature inside the buffer tank

connected to the boiler. The setting of the

temperature of the buffer tank circulation

pump start and stop temperatures is done

as described above. When selecting the

boiler management via thermostat

option the boiler will be controlled by the

signal input from the thermostat, whereas

the options are: thermostat normally

open or thermostat normally closed. Its

type is introduced at a later step on the

controller menu.

In this menu you can

select the type of the

thermostat used (if that

option is selected)

NO

- normally open;

NC

- normally closed.

From this menu, the

following parameters

are configured:

The

dT

parameter sets

the temperature difference of exhaust

gases upon which the controller should

register ignition. The start point of

watching this difference is the moment of

start of the main burner fan in the process

of ignition. From that point on whenever

the temperature of the exhaust gases in

the boiler rises with 5 degrees an ignition

shall be registered and the boiler will go

into normal operating mode.

The next parameter

> 095°C/30 min

.

determines the time after the boiler shift

to normal operating mode during which

the boiler must exceed the specified

temperature of exhaust gases. Upon

fulfillment of this condition the boiler will

register itself in normal working mode.

If the exhaust gases temperature drops

below

85 °C

the boiler will shift into

extinguishing mode

(Error Burnout)

.