34

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

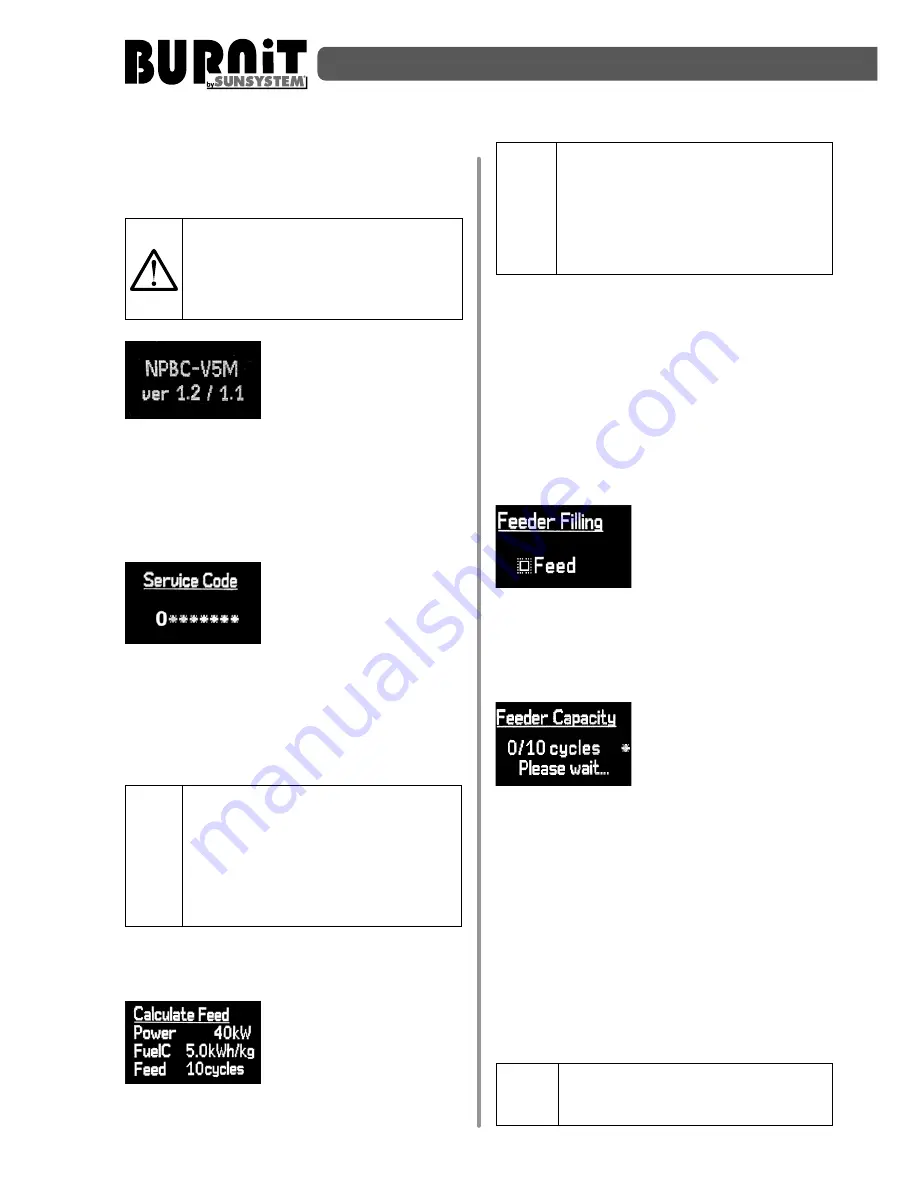

10.3. Installer menu (setting the

combustion parameters in the burner

controller)

CAUTION! We recommend that

this menu be used only by an

authorized installer/service shop

in order to ensure efficient and

safe operation of the equipment

T

o access the settings

adjustment

mode,

simultaneously

press

the “

Enter

” and „

F

”

buttons and hold them

pressed for 4 /

four

/ seconds.

This will display the controller hardware

and software version on the screen. Press

again button “

F

” and this will open the

initial page for the burner settings.

T

o access the service

settings

must

be

entered service code.

Service menu includes

only parameters that

directly affect the boiler combustion

process, and the management of the

installation (depending on the capabilities

of the management of peripheral devices

from the controller to the boiler).

Fuel switching and / or change

the configuration of the heating

installation must be performed

by an authorized installer /

service. Some of these reasons

may affect the safe operation of

the facility.

10.3.1. Menu for automatic dose pellets

for maximum power

Calculation of feeding:

Power

- Enter the

maximum power of the

model of boiler.

Important: Please enter the

exact power. Setting of higher

or lower power than is written

on production label of the boiler

can cause boiler damage or

physical injury.

Fuel C

- Set the calorific value of used

fuel. The calorific value is marked on fuel

package.

Feed

- Determine the number of cycles for

screw calibration. When entering a larger

number of cycles will get more precise

results.

Press

"F"

button to switch to next

submenu.

Filling of auger:

From this menu by

selecting "up arrow"

button

activate

operation of main auger of the boiler

(the auger in fuel hopper). Auger began

working constantly. If the auger is empty

will take about 20 min. to be filled- well.

Capacity of Auger:

When enter this menu,

controller automatically

start to operate 10

cycles. During these operating cycles

the auger Switch-On and Switch-Off

simulating normal operating behavior

for combustion process. Transported by

auger pellets during these cycles should be

collected (use a plastic bag) and weighed

when the last cycle is completed. The

number on right-side of the screen shows

how many cycles you set for execution.

The number on left-side of the screen

shows which cycle is currently running.

Pending completion of all cycles

do not press the buttons display

as it will stop the process!