Operation

- 3.8 -

SMART KNIT

The suggested values for different yarns are as hereafter indicated:

Very thick yarns

1

Thick yarns

3

Medium yarns

5

Fine yarns

(single filament yarn)

6-8

Very fine yarns

(Lycra®)

9-10

Reaction time

(DELAY)

The DELAY parameter allows the adjustment of the sensor to the characteristics of

yarn to be processed

(e.g. elasticity)

, by defining the Reaction Time of the sensor

before signaling a defect. It is possible to program 8 pre-set values:

5 ms - 10 ms - 20 ms - 50 ms - 100 ms - 200 ms - 500 ms - 1000 ms

#

50 ms is the suggested value for very high running speed of the yarn.

#

200 ms is the suggested value for normal yarns.

#

500 ms is the suggested value for elastic yarns.

Start Frequency

(F_START)

This parameter indicates the minimum frequency of image variation, beyond

which the sensor signals that the yarn is running normally

(green LED ON).

It can be programmed to a value ranging between

1

and

10

.

Stop Frequency

(F_STOP)

This parameter indicates the minimum frequency of image variation, below which

the sensor signals that the yarn runs normally

(red LED ON).

It can be programmed to a value ranging between

1

and

10

.

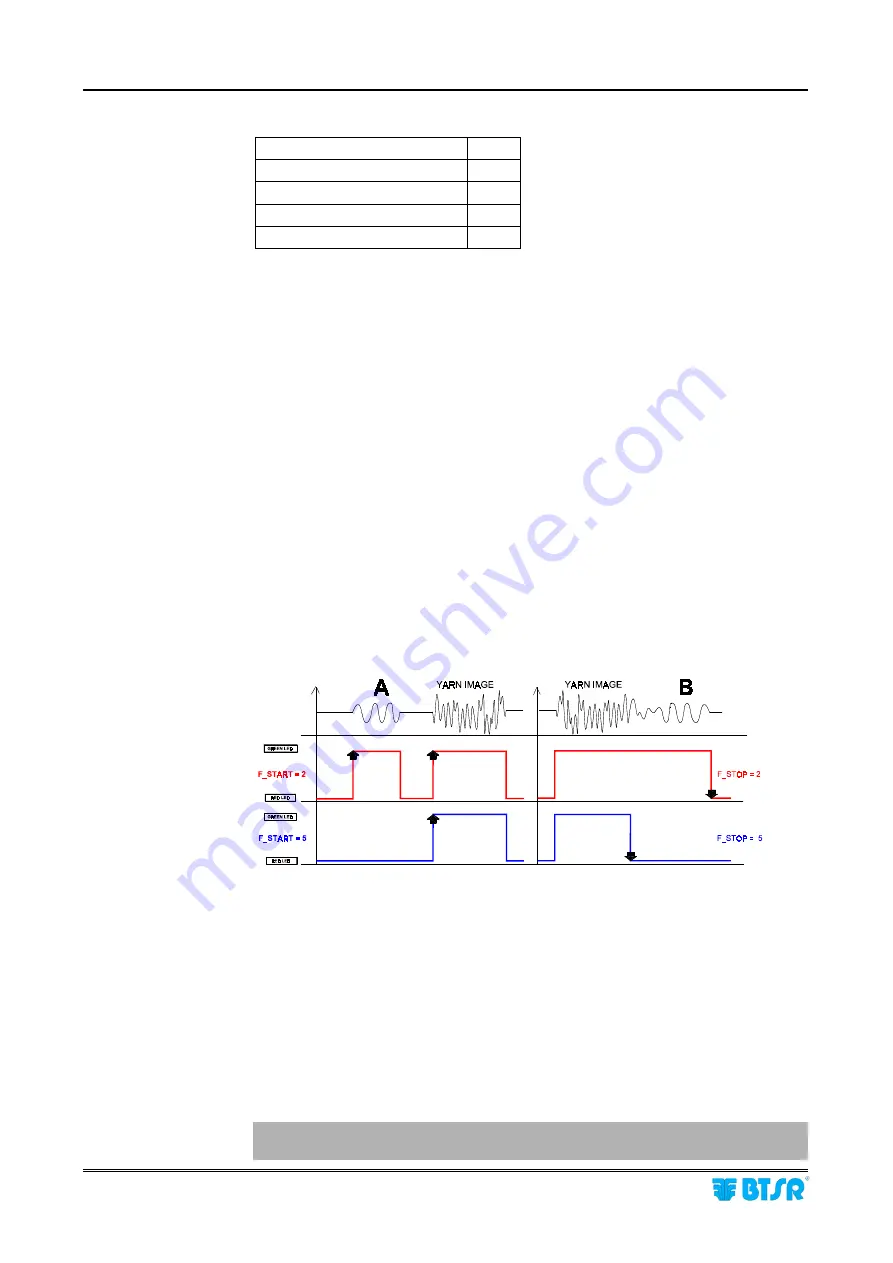

Programming examples for F_START/F_STOP and relevant sensor delays

As the diagram shows, if the F_START and F_STOP value is set low

(e.g. = 2)

,

then the sensor could detect the condition of “running yarn” even though the yarn

is actually still or broken, and is undergoing a light oscillation

(

A

and

B

areas of

the diagram)

. Otherwise, if a higher value is set

(e.g. = 5)

then the image variation

of

A

and

B

areas is not considered sufficient to detect the condition of “running

yarn”. It must be observed, however, that if the yarn detected by the sensor has a

very regular profile

(e.g. Lycra® or single filament yarn)

, the frequency of the

image variation is lower; therefore if a value too high is programmed, the sensor

could not detect the “running yarn” condition

(or it would detect it with excessive

delay)

. This is why the F_START and F_STOP values can be “calibrated”

according to the article to be processed, in order to obtain the condition of optimal

detection for that particular article.

!

In the presence of frequent errors detected by the sensors, it is suggested to

gradually change such values until an optimal condition is achieved.

Содержание IS3F-485

Страница 1: ...SMART KNIT IS3F 485 YARN CONTROL SYSTEM Operating Manual Rev 1 0 January 2006 ENGLISH ...

Страница 6: ...Introduction I 2 SMART KNIT Page intentionally left blank ...

Страница 11: ...Technical Data and Installation SMART KNIT 2 3 SM DIN Modules Interconnection ...

Страница 38: ...Operation 3 26 SMART KNIT Page intentionally left blank ...

Страница 44: ...Troubleshooting and Maintenance 4 6 SMART KNIT Page intentionally left blank ...