1.4 - System description

8

TCT-2301 Product introduction

M2007/3en

©BTG 2004

1.4 System description

The system consists of a probe (1) connected by an optical fiber to an

electronics box (2) The probe contains only optical fibers. A ball valve

arrangement that is welded to the pipe system make it possible to remove

the probe without interrupting the process.

The electronics box contains electronics card, power supply, electrical

and optical connections. To set up the transmitter a hand-held terminal

(3) type SPC-1000 must first be connected (see fig 4).

The hand-held terminal allows the operator to set up and monitor the sys-

tem. It includes a liquid crystal display (LCD) with a touchscreen key-

pad.

1.5 Typical applications

•

Control of flotation systems or wash stages for de-inking of

recycled fibers

•

Control of screening and cyclone cleaning processes

•

Monitoring of TMP/CTMP steam and hot-water recovery

systems

CRC

1

3

5

2

8

4

9

7

6

Enter

Sample

Terminal

Total Consistency

Transmitter

TCT-2300

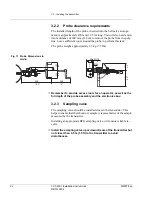

Fig 4 Typical control loop for

consistency control of the TCT-

2301

1 Measuring probe

2 Electronics box

3 Hand-held terminal SPC-1000

4 3/4 wire system for analog output

5 Controller/recorder (DCS)

6 Dilution water valve

7 Pulp chest with sufficient mixing

8 Stock pump

9 BTG sampling valve type MPS-1000