4 - 40

Adjustment

How to reset the counter of the maintenance.

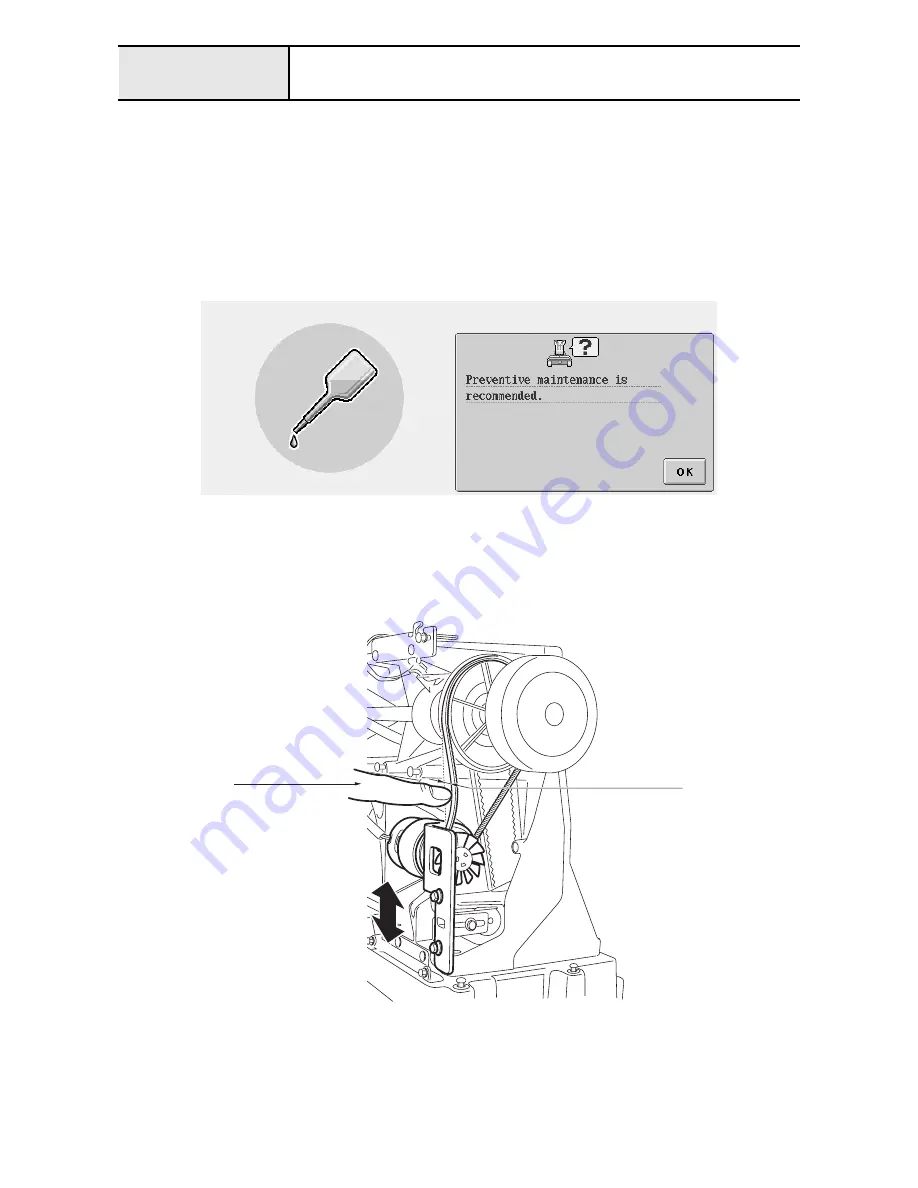

When the operating time of the machine becomes 1500h, because following the MSG is displayed, and follow

the following instructions. And then maintain the maintenance following by 6-2, 6-3, 6-4, and finally reset the

counter.

NOTE •

The MSG (shown below) will appear (on the LCD) when the machine is turned on after an hour counter

reaches 1500 hours (*the MSG appears up to 3 times, and will not come up when the machine is turned on

for the 4th time.). If an hour counter is still not reset (any maintenance has not been done) after the MSG, the

MSG will come up again at 1600 hours and 1700 hours (also up to 3 times each). When an hour counter

reaches 2000 hours, “Preventative maintenance is recommended 2000 hours exceeded” MSG will appear

on the LCD every time the machine is turned on until the hour counter is reset.

Check the motor (Suggested to replace every 1500h) tension during maintenance process.

*Key point

• Refer to Motor belt tension adjustment (4-19)

0.98N (100g)

2.0 - 3.5mm

1

Содержание PR-600II

Страница 1: ......

Страница 2: ......

Страница 20: ...2 2 Main parts Main unit ...

Страница 33: ...2 15 Disassembly Feed unit Main unit ...

Страница 44: ...2 26 Needle thread unit Main unit ...

Страница 47: ...2 29 Disassembly Needle bar change unit Main unit ...

Страница 50: ...2 32 Thread wiper unit Main unit ...

Страница 54: ...2 36 Needle bar unit Main unit ...

Страница 60: ...2 42 Upper shaft unit Main unit ...

Страница 70: ...2 52 Lower shaft unit Main unit ...

Страница 73: ...2 55 Disassembly Power unit Main unit ...

Страница 78: ...2 60 Thread cut unit Main unit ...

Страница 82: ...2 64 Thread tension unit Main unit ...

Страница 91: ...2 73 Disassembly Operation panel Main unit ...

Страница 98: ...2 80 ...

Страница 100: ...3 2 Operation panel Main unit ...

Страница 108: ...3 10 Thread tension unit Main unit ...

Страница 118: ...3 20 Thread cut unit Main unit ...

Страница 122: ...3 24 Power unit Main unit ...

Страница 128: ...3 30 Lower shaft unit Main unit ...

Страница 132: ...3 34 Upper shaft unit Main unit ...

Страница 147: ...3 49 Assembly Needle bar unit Main unit ...

Страница 157: ...3 59 Assembly Thread wiper unit Main unit ...

Страница 162: ...3 64 Needle bar change unit Main unit ...

Страница 166: ...3 68 Needle thread unit Main unit ...

Страница 170: ...3 72 Feed unit Main unit ...

Страница 188: ...3 90 Main unit Main unit ...

Страница 206: ...4 4 Inspection Blunt needle 1 Touch the needle tip with your finger to check that the needle tip is not blunt ...

Страница 244: ...4 4 Inspection Blunt needle 1 Touch the needle tip with your finger to check that the needle tip is not blunt ...

Страница 282: ...4 42 ...

Страница 311: ...6 1 6Maintenance ...

Страница 333: ......