CHAPTER 6 TROUBLESHOOTING

6-46

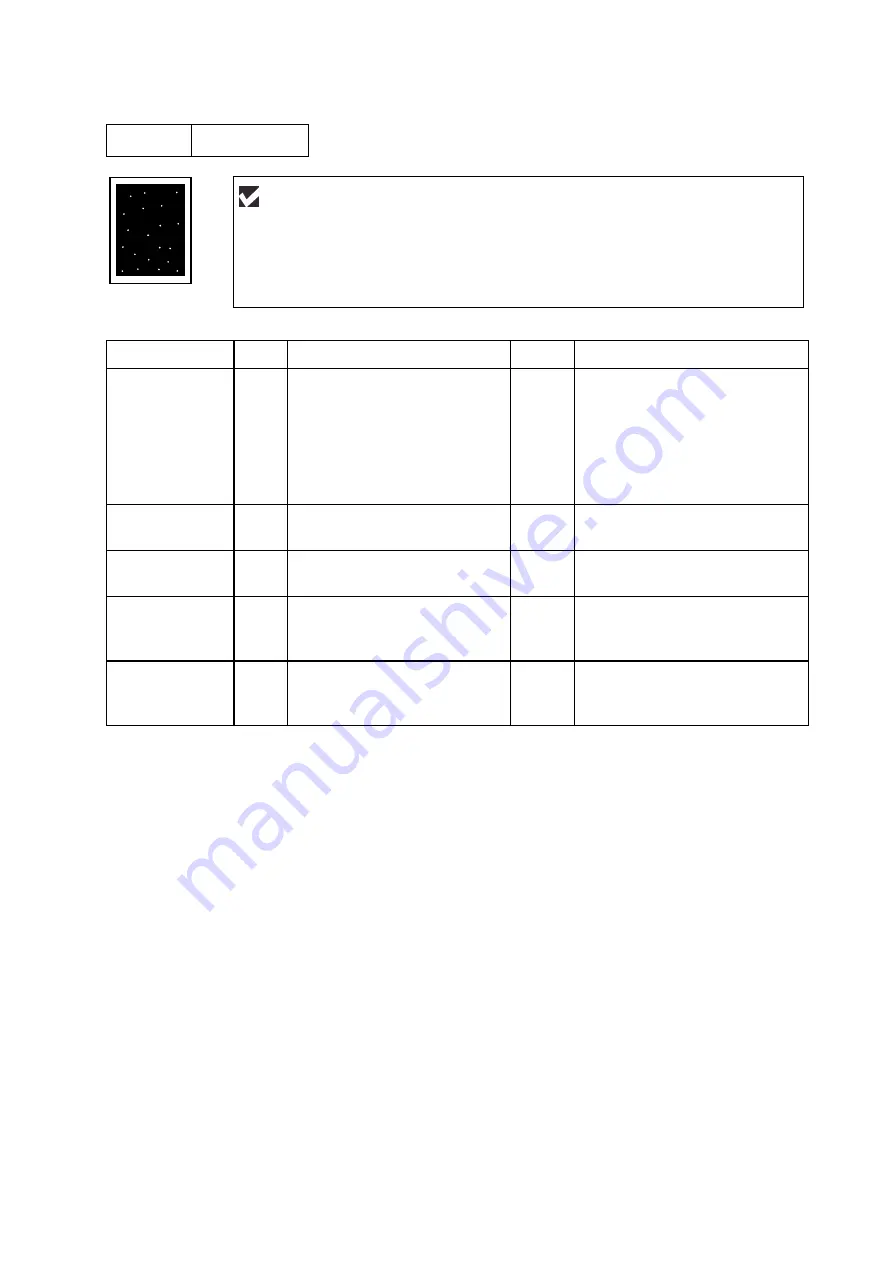

I-15

White spots

Possible cause

Step

Check

Result

Remedy

Drum unit failure

1

Are the white spot at 94mm

intervals?

Yes

1) If toner or glue remains

stuck, wipe it off gently with a

cotton swab. (Refer to

NOTE

in the next page.)

2) If the drum surface is

scratched, replace the drum

unit.

Drum unit failure

2

Is the problem solved after

replacing the drum unit?

Yes

Replace the drum unit.

No toner

3

Is the toner in the toner

cartridge almost empty?

Yes

Replace the toner cartridge with

a new one.

Print paper

4

Is the problem solved after

changing to specified freshly

unpacked paper?

Yes

Damp (wet) paper might be

used. Recommend to change

freshly unpacked paper.

Environment

5

Does the problem still appear

after the printer has warmed

up?

Yes

1) Replace the drum unit.

2) Advise the user of the

specified print environment.

User Check

(1) If the problem is not solved after printing a few pages, the drum unit may have

glue from label stock on the photosensitive drum surface. Refer to Step 1 in the

table below and

NOTE

in the next page.

(2) The drum unit may be damaged. Install a new drum unit.

Содержание HL-1870N

Страница 15: ...HL 1850 1870N SERVICE MANUAL xiii ...

Страница 77: ...CHAPTER 2 INSTALLATION AND BASIC OPERATION 2 48 ...

Страница 82: ...HL 1850 1870N SERVICE MANUAL 3 5 Fig 3 5 ...

Страница 83: ...CHAPTER 3 THEORY OF OPERATION 3 6 1 3 2 ROM Two 64 Mbits ROMs x 16 bit are fitted Fig 3 6 HL 1850 HL 1870N ...

Страница 85: ...CHAPTER 3 THEORY OF OPERATION 3 8 1 3 4 SDRAM A 64M bit SDRAM x 32 bits is used as the RAM Fig 3 8 HL 1850 ...

Страница 86: ...HL 1850 1870N SERVICE MANUAL 3 9 Two 64M bit SDRAMs x 16 bits are used as the RAM Fig 3 9 HL 1870N ...

Страница 91: ...CHAPTER 3 THEORY OF OPERATION 3 14 Fig 3 15 ...

Страница 101: ...CHAPTER 3 THEORY OF OPERATION 3 24 ...

Страница 109: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 2 ...

Страница 131: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 24 Fig 4 39 ...

Страница 141: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 34 Never touch the surface of the heat roller ...

Страница 148: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 41 ...

Страница 158: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 51 Fig 4 80 ...

Страница 160: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 53 Fig 4 82 ...

Страница 167: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 60 Fig 4 91 ...

Страница 169: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 62 Fig 4 93 ...

Страница 172: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 65 Fig 4 97 ...

Страница 174: ...CHAPTER 4 DISASSEMBLY AND RE ASSEMBLY 4 67 3 27 Harness Winding Form ...

Страница 183: ...CHAPTER 5 PERIODIC MAINTENANCE 5 8 ...

Страница 186: ...HL 1850 1870N SERVICE MANUAL 5 11 ...

Страница 194: ...CHAPTER 6 TROUBLESHOOTING 6 8 error in this chapter ...

Страница 202: ...CHAPTER 6 TROUBLESHOOTING 6 16 ...

Страница 205: ...HL 1850 1870N SERVICE MANUAL 6 19 ...

Страница 210: ...CHAPTER 6 TROUBLESHOOTING 6 24 ...

Страница 237: ...HL 1850 1870N SERVICE MANUAL 6 51 No Refer and compare with I 15 ...

Страница 255: ...HL 1850 1870N SERVICE MANUAL 6 69 ...

Страница 261: ...CHAPTER 7 HIDDEN FUNCTIONS 7 6 DRAM CHECK START START DRAM TEST Tests DRAM data ...

Страница 270: ...HL 1850 1870N SERVICE MANUAL 7 15 ...

Страница 271: ......

Страница 272: ...Appendix 1 Connection Diagram HL 1850 1870N A 1 ...

Страница 273: ...Appendix 2 Main PCB Circuit Diagram HL 1850 1870N 1 6 CODE LJ8453001 B512078CIR 1 6 A 2 NAME ...

Страница 274: ...Appendix 3 Main PCB Circuit Diagram HL 1850 1870N 2 6 CODE LJ8453001 B512078CIR 2 6 A 3 NAME ...

Страница 275: ...Appendix 4 Main PCB Circuit Diagram HL 1850 1870N 3 6 CODE LJ8453001 B512078CIR 3 6 A 4 NAME ...

Страница 276: ...Appendix 5 Main PCB Circuit Diagram HL 1850 1870N 4 6 CODE LJ8453001 B512078CIR 4 6 A 5 NAME ...

Страница 277: ...Appendix 6 Main PCB Circuit Diagram HL 1850 1870N 5 6 CODE LJ8453001 B512078CIR 5 6 A 6 NAME ...

Страница 278: ...Appendix 7 Main PCB Circuit Diagram HL 1850 1870N 6 6 CODE LJ8453001 B512078CIR 6 6 A 7 NAME ...

Страница 281: ...Appendix 10 Network Board PCB Circuit Diagram HL 1850 1870N CODE LJ8439001 A 10 NAME B512058CIR ...

Страница 282: ...Appendix 11 Low voltage Power Supply PCB Circuit Diagram 100V A 11 NAME Low voltage PS Circuit 100V ...

Страница 283: ...Appendix 12 Low voltage Power Supply PCB Circuit Diagram 200V A 12 NAME Low voltage PS Circuit 200V ...

Страница 284: ...Appendix 13 High voltage Power Supply PCB Circuit Diagram A 13 NAME High voltage PS Circuit ...

Страница 303: ...APPENDIX A 32 ...