Brookfield Engineering Labs., Inc.

Page 82

Manual No. M13-167-A0415

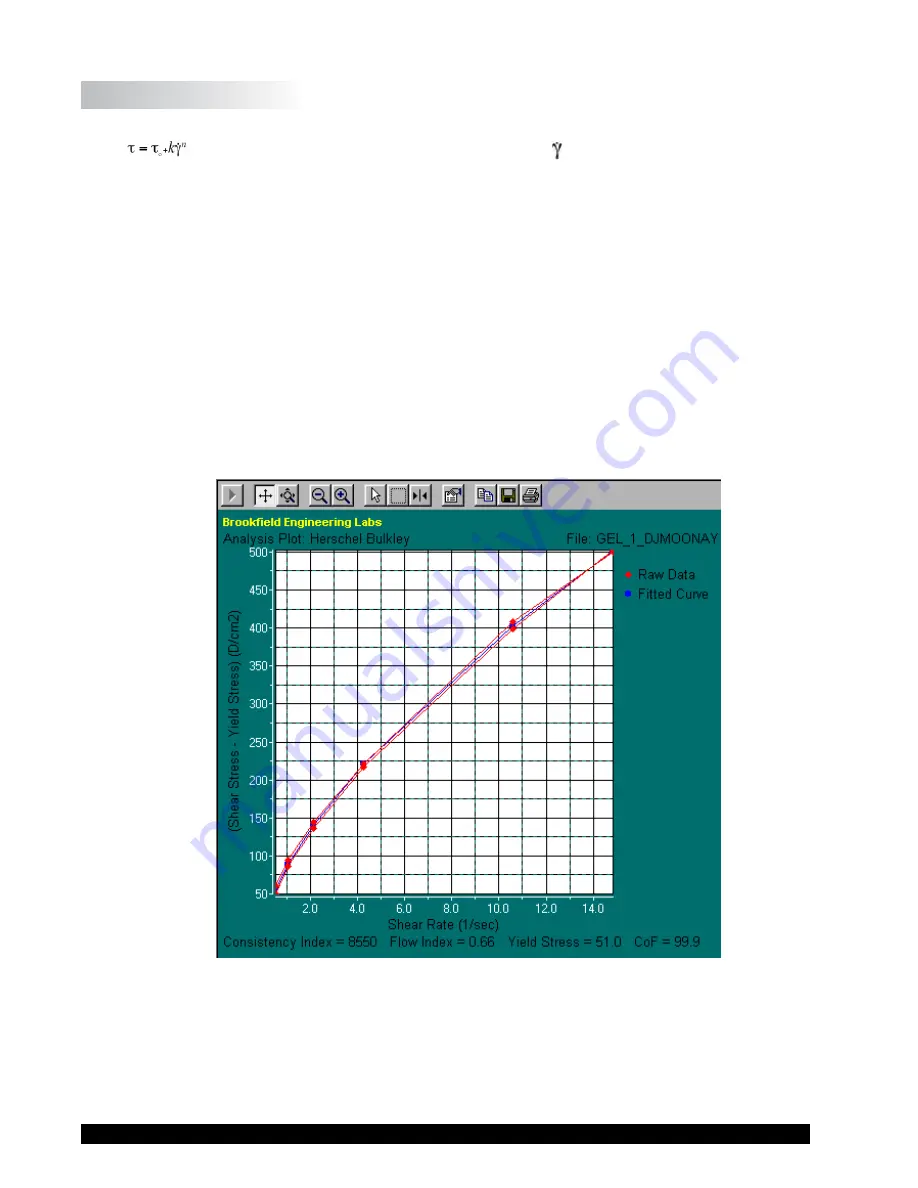

VII.2 The Herschel-Bulkley Model

(

τ

= shear stress,

τ

o

= yield stress,

k

= consistency index,

= shear rate, and

n

= flow index)

What does it tell you?

The Herschel-Bulkley model is simply the Power Law model with the addition of

τ

o

for yield

stress. Yield stress,

τ

o

, denotes how much shear stress is required to initiate flow. This model also

provides a consistency index,

k

, which is a product’s viscosity at 1 reciprocal second, and a flow

index,

n

, which indicates the degree with which a material exhibits non-Newtonian flow behavior.

Since Newtonian materials have linear shear stress vs. shear rate behavior and

n

describes the

degree of non-Newtonian flow, the flow index essentially indicates how “non-linear” a material

is. For Herschel-Bulkley fluids,

n

will always be greater than or less than 1.

When

n

< 1 the product is shear-thinning or Pseudoplastic. This means the apparent viscosity

decreases as shear rate increases. The closer

n

is to 0, the more shear thinning the material is.

When

n

> 1 the product is shear-thickening or Dilatant. It’s apparent viscosity increases as shear

rate increases.

VII-2

When should you use it?

The Herschel-Bulkley model should be used with non-Newtonian, time-dependent materials that

have a yield stress. Products with a yield stress only begin to flow after a certain amount of shear

stress is applied. As a result, the flow curve intersects the y-axis at a point greater than 0. After