7. Before dismantling, secure the motor and power supply against falling or

movement before disconnecting the mechanical connections.

8. Dismantle the motor from the machine.

9. Log all measures taken in the commissioning report.

13.3.2

Maintenance / Repair

Increase availability with regular preventive maintenance measures. Notice

the information in the maintenance schedule of the machine manufacturer

and the following details regarding maintenance measures and intervals for

the motor.

Danger of explosion, fire or danger to life due

to sparking when working in hazardous

areas!

DANGER

Do only work on the motor in non explosible atmosphere and in de-energized

state.

Heed the safety instructions according to DIN EN 50110-1:

1. Disconnect.

2. Protect the system or plant against restart.

3. Determine de-energization.

4. Ground and short-out.

5. Cover or shield any adjacent live parts.

Before starting to work, check with an appropriate measuring device (e.g. an

multimeter) whether parts of the system are still under residual voltage (e.g.

caused by capacitors, etc.). Wait for their discharging time.

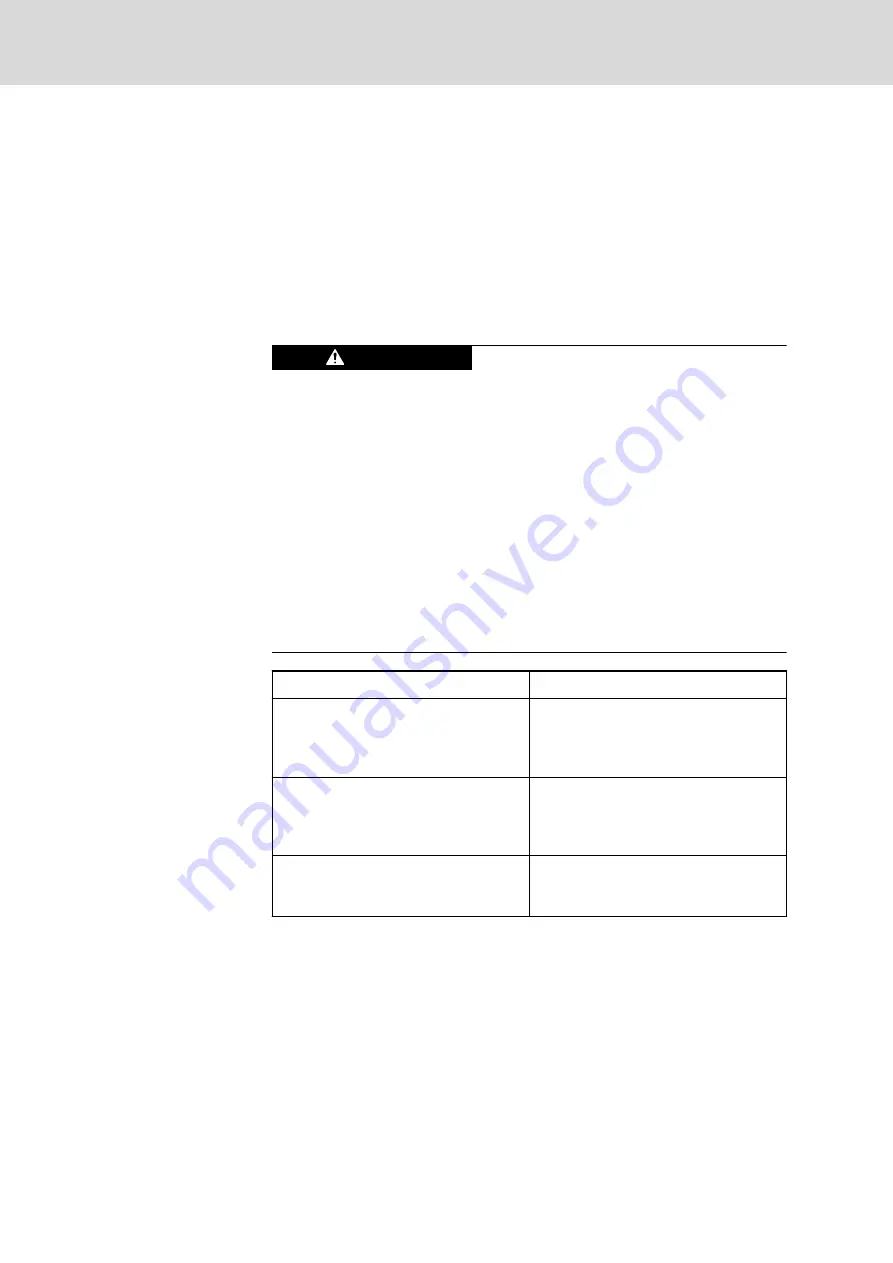

Maintenance

Measure

Interval

Check the mechanical and electrical con‐

nections.

According to the guidelines of the ma‐

chine's maintenance schedule, however,

at least once every 1,000 operating

hours.

Check the machine for smooth running,

vibrations and bearing noises.

According to the guidelines of the ma‐

chine's maintenance schedule, however,

at least once every 1,000 operating

hours.

Remove dust, chips and other dirt from

the motor housing, cooling fins and the

connections.

Depending on the degree of soiling, but

after one operating year at the latest.

Fig.13-1:

Maintenance measures

Repair

MKE must be repaired by the Rexroth service. The following repairs can be

done by the Rexroth service for example:

●

Replacement of motor encoder

●

Replacement of the shaft sealing ring

●

Repair / Change of damaged flameproof joints

●

...

Bosch Rexroth AG

DOK-MOTOR*-MKE*GEN2***-PR06-EN-P

Rexroth MKE Synchronous Motors for Potentially Explosive Areas acc. to ATEX and UL/CSA

122/135

Commissioning, Operation and Maintenance

LSA Control S.L. www.lsa-control.com [email protected] (+34) 960 62 43 01