DANGER

Dangerous movements! Danger to life, risk of injury, severe bodily harm

or material damage!

To avoid accidents, bodily harm and/or material damage:

●

For the above reasons, ensure personal safety by means of qualified and

tested higher-level monitoring devices or measures integrated in the in‐

stallation.

They have to be provided for by the user according to the specific condi‐

tions within the installation and a hazard and fault analysis. The safety

regulations applicable for the installation have to be taken into consider‐

ation. Unintended machine motion or other malfunction is possible if safety

devices are disabled, bypassed or not activated.

●

Keep free and clear of the machine’s range of motion and moving parts.

Possible measures to prevent people from accidentally entering the ma‐

chine’s range of motion:

–

use safety fences

–

use safety guards

–

use protective coverings

–

install light curtains or light barriers

●

Fences and coverings must be strong enough to resist maximum possible

momentum.

●

Mount the emergency stop switch in the immediate reach of the operator.

Verify that the emergency stop works before commissioning. Do not op‐

erate the device if the emergency stop switch is not working.

●

Isolate the drive power connection by means of an emergency stop circuit

or use a safety related starting lockout to prevent unintentional start.

●

Make sure that the drives are brought to a safe standstill before accessing

or entering the danger zone.

●

Additionally secure vertical axes against falling or dropping after switching

off the motor power by, for example:

–

mechanically securing the vertical axes,

–

adding an external braking/arrester/clamping mechanism or

–

ensuring sufficient equilibration of the vertical axes.

The standard equipment motor brake or an external brake controlled by

the drive controller are not sufficient to guarantee personal safety!

●

Disconnect electrical power to the equipment using a master switch and

secure the switch against reconnection for:

–

maintenance and repair work

–

cleaning of equipment

–

long periods of discontinued equipment use

●

Prevent the operation of high-frequency, remote control and radio equip‐

ment near electronics circuits and supply leads. If the use of such devices

cannot be avoided, verify the system and the installation for possible mal‐

functions in all possible positions of normal use before initial commission‐

ing. If necessary, perform a special electromagnetic compatibility (EMC)

test on the installation.

12/45

Bosch Rexroth AG | Electric Drives

and Controls

Rexroth IndraControl VAU 01.1Z | Project Planning Manual

Safety Instructions for Electric Drives and Controls

Содержание Rexroth IndraControl VAU 01.1Z

Страница 1: ...Electric Drives and Controls Pneumatics Service Linear Motion and Assembly Technologies Hydraulics ...

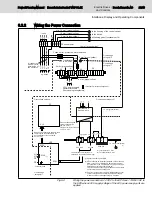

Страница 36: ...34 45 Bosch Rexroth AG Electric Drives and Controls Rexroth IndraControl VAU 01 1Z Project Planning Manual ...

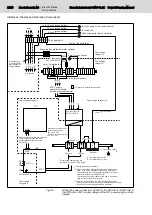

Страница 38: ...36 45 Bosch Rexroth AG Electric Drives and Controls Rexroth IndraControl VAU 01 1Z Project Planning Manual ...

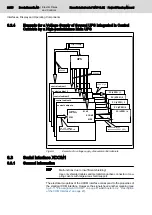

Страница 40: ...38 45 Bosch Rexroth AG Electric Drives and Controls Rexroth IndraControl VAU 01 1Z Project Planning Manual ...

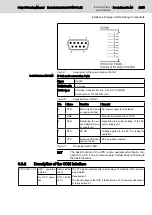

Страница 44: ...42 45 Bosch Rexroth AG Electric Drives and Controls Rexroth IndraControl VAU 01 1Z Project Planning Manual ...

Страница 46: ...44 45 Bosch Rexroth AG Electric Drives and Controls Rexroth IndraControl VAU 01 1Z Project Planning Manual ...