Magnetics that count

BOGEN Magnetics GmbH

· Potsdamer Straße 12 - 13 · 14163 Berlin · Germany

Fon +49 (0) 30 81 00 02 - 0 · Fax +49 (0) 30 81 00 02 - 60 · [email protected] · www.bogen-magnetics.com

AKS17 ins

tallation and oper

ation ins

truction manual (2021/06/16)

8/14

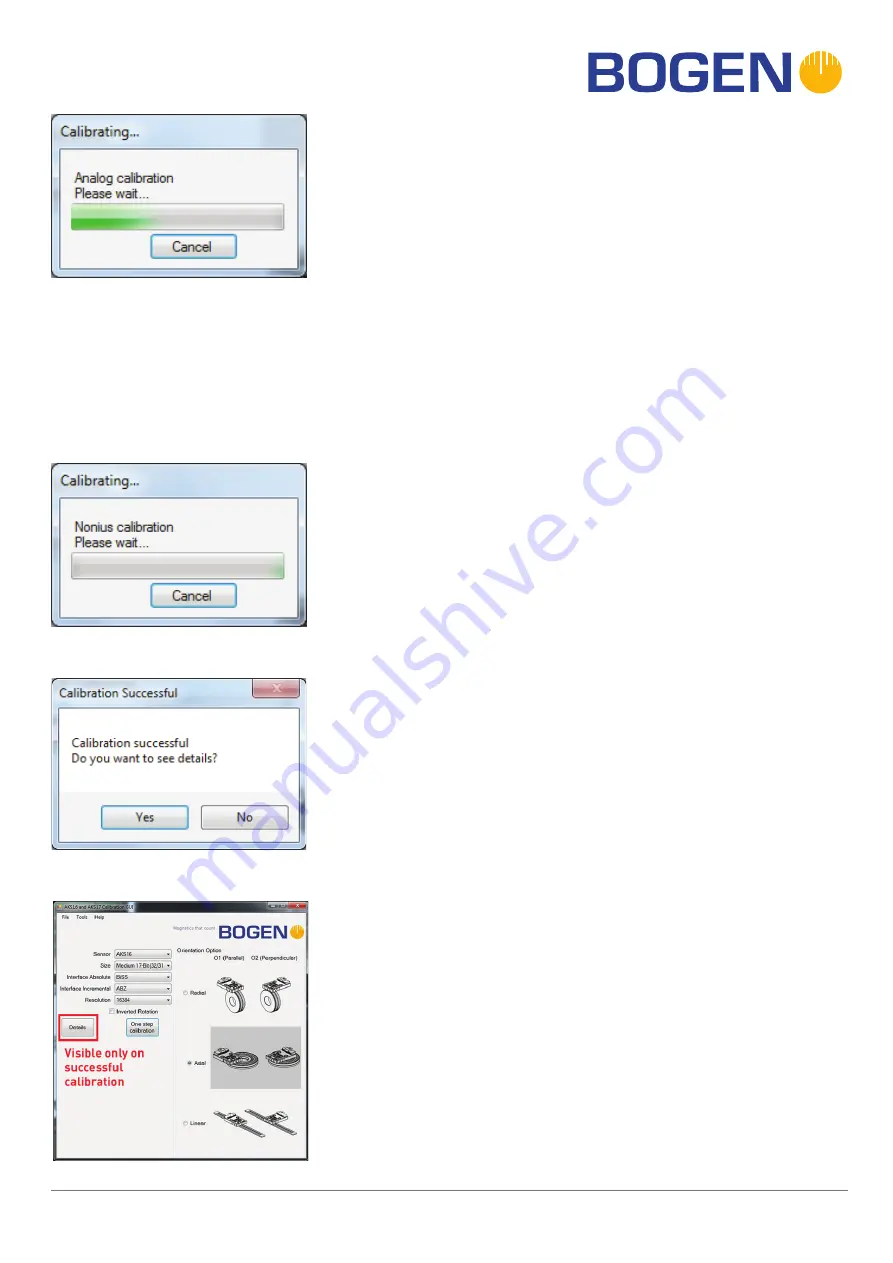

The next step is the nonius calibration where the sensor uses the

calibrated analog parameters to read out the sensor. If the read

out results contain values that are out of range, the calibration

considered to be failed and has to be done again. In case of linear

calibration the user will be prompt with a count down window on the

nonius calibration.

The user can continue and save in case of bad nonius calibration (not

recommended but available for extreme situations).

Afterwards the program starts the automatic calibration operation and

interacts and shows the user the current process.

In analog calibration the user will be prompt to adjust the current

X-Y-position or to verify the air gap between the sensor and the scale

or both if needed. In case of linear calibration the user will be prompt

with the countdown window on every iteration.

The user has to move the magnetic target during the calibration

process. In linear application the user can move the scale in a user-

defined direction after the countdown is over. The duration of the

movement depends on the “Calibration Setup”.

Depending on the result of the analog calibration the user has the

choice to repeat the calibration or to continue without adjusting the

current position (not recommended but possible).

If the calibration has been successful the user will be informed about

this. Now the user has the choice if he wants to see details or not. The

details contain several calibration charts as seen on page 8.

A “Details” button will be visible after calibration is finished. After

pressing this button a new window will be shown. It contains all

calibration information details (for more information on details please

refer to “Details” section).

Disconnect the cables from the PC, programmer AKS17 and sensing

head. The sensing head is now ready for use. Connect the sensing

head with your devices or power unit as desired for your application.