Magnetics that count

BOGEN Magnetics GmbH

· Potsdamer Straße 12 - 13 · 14163 Berlin · Germany

Fon +49 (0) 30 81 00 02 - 0 · Fax +49 (0) 30 81 00 02 - 60 · [email protected] · www.bogen-magnetics.com

AKS17 ins

tallation and oper

ation ins

truction manual (2021/06/16)

7/14

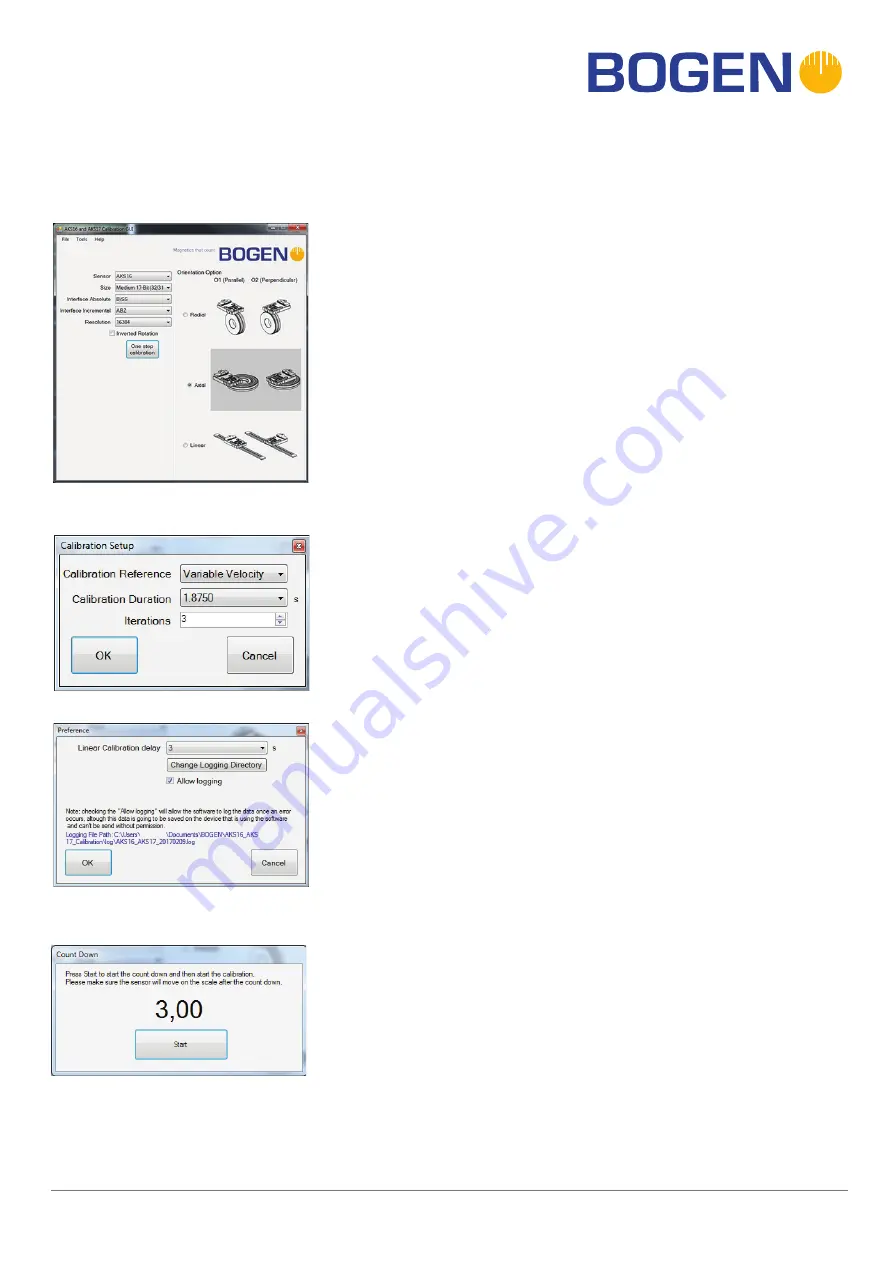

Configuring the AKS17 Sensing Head

The software will calibrate the sensing head for the present mechanical alignment. Make sure the AKS17

sensing head is now mounted correctly including all devices for calibration. Ensure, that the AKS17 is

connected to the PC as described above.

In case of radial or axial orientation start rotating the scale (or move

the sensor around the scale) and press “One step calibration”.

In case of linear orientation make sure the sensor will start moving

after the delay, then press “Start”.

Note: The user should just move the sensor manually at the end of the

delay countdown.

Start the BOGEN calibration software “AKS16 and AKS17

CalibrationGUI”.

Choose “AKS17” from the “Sensor” combo box.

Choose the desired sensor parameters (see technical data sheet for

full listing of sensor parameters). Please note that the resolution

combo box is only available if interface incremental is “ABZ” which

describes the incremental ABZ resolution. When “UVW” is chosen

another combo boc will appear. Here the user can choose the pole

pairs that correspond to UVW (see datasheet).

Choose the orientation option from the right side of the window by

clicking on the photo or the radio button. Make sure it is how the

sensor is mounted.

From “File” in the main menu the sub menu items “Calibration Setup”

and “Preference” can be reached. These configurations are set by

default as seen in the figures and they will be saved and reused every

time the program starts. For a detailled description please refer to

“Tips on the software and calibration”.

Connect the sensor to the adapter and then the adapter to the PC.

Please make sure the sensor is mounted properly within the tolerance

(see datasheet).