Maintenance

6.3

Maintenance work between scheduled services

Page 62

Operating instructions for S 40-3...S 150-3 series screw compressors

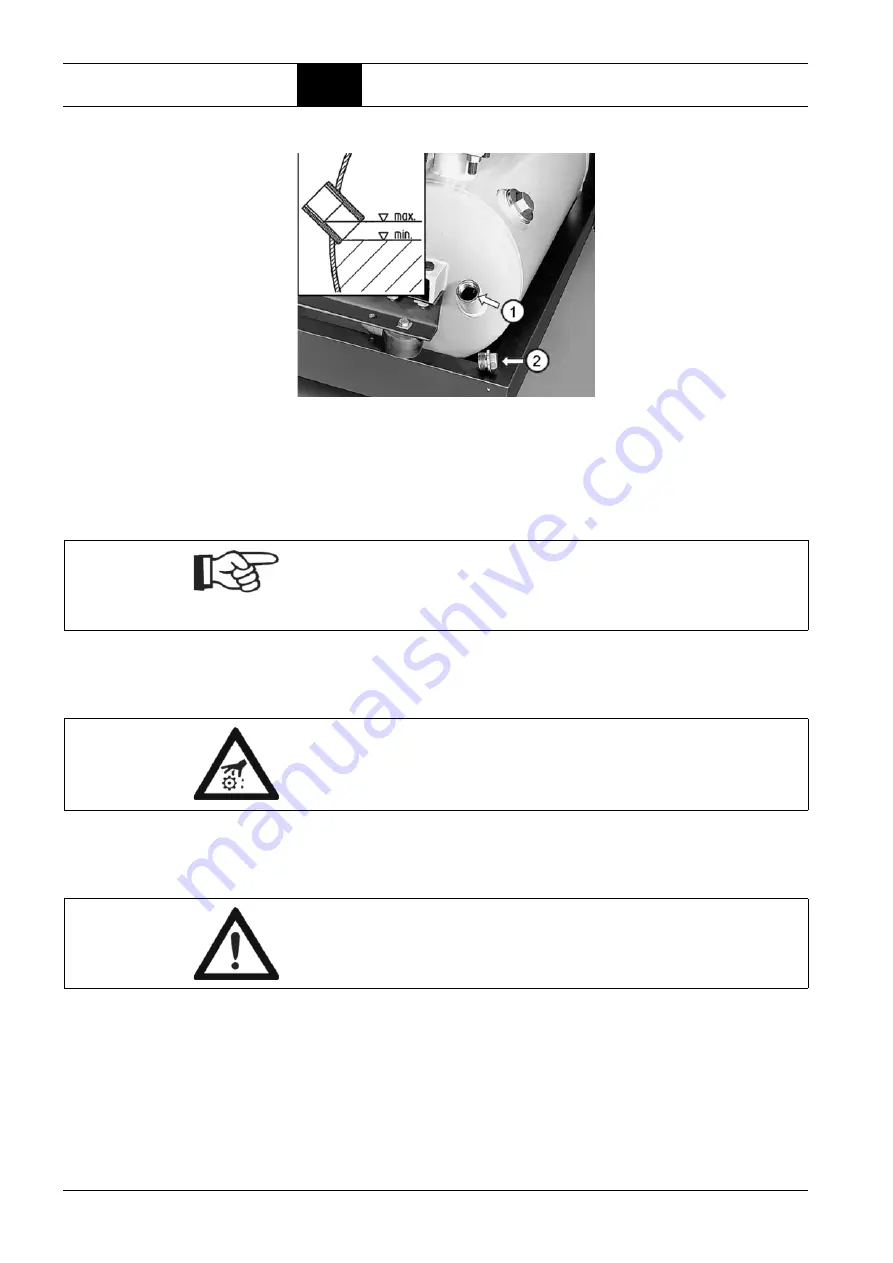

Fig. 6.4: Checking the oil level, topping up with oil

Every 1,500 operating

hours: Clean the oil

cooler (air cooling)

Clean

the air/oil cooler:

– After 1,500 operating hours.

Cleaning the compressed air/oil cooler

1. Switch off the compressor with the OFF button.

2. Remove the right side of the sound insulation hood.

3. Remove the maintenance opening on the cooling air duct box.

4. Remove accumulated dirt with a fibre brush.

5. Blow out the dirt with compressed air (1) in the opposite direction to the nor-

mal cooling air flow (see figure below).

NOTICE!

The service life of the compressed air/oil cooling unit depends on the degree

of soiling (dust, oil vapour) of the suctioned cooling air. Extreme external soil-

ing of the cooling unit leads to an increased temperature in the oil circuit.

WARNING: Risk of injury!

Press the emergency stop button, use the mains disconnection device to iso-

late the compressor from the power supply and fix a padlock to prevent the

power from being switched on again unintentionally.

WARNING!

Do not use sharp objects to clean the cooler!

Sharp objects could damage the cooler.