Commissioning

This section contains some important general information about commissioning a robot that is equipped with

an AIRSKIN® Safetyflange. This includes initial commissioning or commissioning after complete or partial dis-

assembly and reassembly, installation on a different robot, modification of the robot, and comprehensive mainte-

nance.

7.1 Preparatory work before AIRSKIN® is switched on

Prior to working with a robot that uses the AIRSKIN® Safetyflange as a safety function, it is assumed that any

given individual will be familiar with

• the robot to which the AIRSKIN® Safetyflange is attached

• the operation of the robot to which the AIRSKIN® Safetyflange is attached

• the workplace / work station

• the task / mode of operation

• any additional safety features that have been installed

• the immediate environment

• measures to be taken in an emergency.

Read the log from the previous shift / previous day and check that access points to the electrical installations

are closed. You can find information about additional preparations that must be made before any operation in

7.2 Reconfigure AIRSKIN®

In order to use the AIRSKIN® Safetyflange on a robot, the AIRSKIN® System must be reconfigured before it is first

used and following any modification (e.g. exchange of a part).

You should check the following items before reconfiguration:

• Is any cable visible on the outside or hanging loose?

• Is the AIRSKIN® Pad mounted firmly and correctly on the AIRSKIN® Safetyflange?

• The connection hoses on any companion pads show no kinks or bruises.

• Is the AIRSKIN® Connection Box correctly connected to the controller?

• If the AIRSKIN® Connection Box is supplied with

+

24 V DC

by the controller, this connection must be checked

too.

• If the AIRSKIN® Connection Box is supplied with

+

24 V DC

via an external source of power, this connection

and potential equalization with the controller must be checked too.

• The AIRSKIN® connection cable is plugged into the AIRSKIN® Connection Box.

• The controller or the external source of power supplies the AIRSKIN® Connection Box with

+

24 V DC

.

AIRSKIN® is reconfigured by first holding the Spark button (

) and then pressing the Restart button until

the status LEDs on the AIRSKIN® Connection Box light up again (

). When the Restart button is released,

the light of the two LEDs goes out again (

). Upon successful reconfiguration, all pads light up green.

Otherwise, the reconfiguration must be repeated by pressing the Restart button again. Then the Spark button can

also be released (

). Briefly press the Restart button to start the AIRSKIN® system (

). Any

blue flashing pads have to be actuated once (

Содержание AIRSKIN

Страница 1: ...SAFETYFLANGE OPERATING MANUAL 2020 06 30 v1 2 English Translation...

Страница 17: ...A A A A 135 5 1 63 13 0 5 82 5 89 0 5 Fig 3 3 Dimensions of the AIRSKIN Safety ange in mm 13 62...

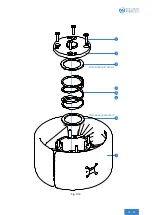

Страница 25: ...1 2 3 Plain Bearing Washer 1 5 4 6 3 Plain Bearing Washer 2 7 Fig 4 4 Exchanging the spring 21 62...

Страница 57: ...1 2 3 Plain Bearing Washer 1 5 4 6 3 Plain Bearing Washer 2 7 Fig 10 2 53 62...

Страница 66: ...15 Declaration of Conformity and manufacturer 62 62...