4

www.blaubergventilatoren.de

VENTO A50 / A50-1 / A50 S / A50-1 S

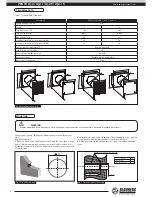

DESIGN AND OPERATING LOGIC

The unit consists of a telescopic duct with adjustable length, a ventilation

unit and an outer ventilation hood.

Two filters and a ceramic heat accumulator (regenerator) are installed

inside of the telescopic air duct. The round Ø 150 mm air duct is made of

plastic and has an adjustable length:

– 240 up to 460 mm for the models VENTO A50 / A50-1;

– 120 up to 420 mm for the models VENTO A50 S / A50-1 S.

The unit is equipped with a high-tech ceramic heat accumulator with

regenerating efficiency up to 91%. Due to the cellular structure is has larger

contact surface and higher efficiency. The heat accumulator is featured with

excellent heat-conducting properties and thermal energy storage capacity.

The ceramic heat accumulator is used for extract air heat energy recovery

for warming up of supply air. The cord inside the regenerator facilitates its

removal for maintenance. The regenerator is installed on the insulation

material used as a sealer as well.

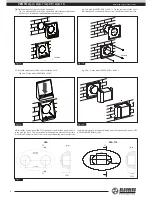

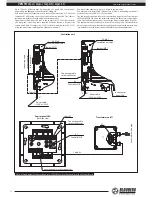

The ventilation unit must be installed on inner side of the wall. It is

equipped with automatic shutters that close the air duct when the unit is off.

Air is supplied and extracted with an axial reversible EC-fan with low

energy demand. The motor has overheating protection and ball bearings for

longer service life.

Two built-in filters with total filter class G3 are used for supply and extract

air filtration and the regenerator anti-soiling protection.

The outer ventilation hood must be installed on outer side of the building

to prevent ingress of large objects and water into the unit.

The integrated automation enables two-speed operation of the unit

(minimum or maximum speed):

– ventilation mode (air supply or air extract);

– reversible operation mode with heat regeneration.

The external control and power unit SEA-T12 or the control panel SEA is

used for operation mode control.

The delivery set of the units VENTO A50 Pro / A50-1 Pro / A50 S Pro / A50-1

S Pro includes the control and power unit SEA-T12 consisting of the control

panel SEA and the 12W transformer AT-12.

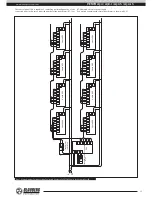

The single control and power unit SEA-T12 enables connection up to 4

units and their integration into a central controlled ventilation system.

The following components are required to arrange a central controlled

ventilation system consisting of from 4 up to 12 ventilation units:

– required number of VENTO A50 units (no control unit is included);

– control panel SEA;

– 40W power transformer AT-40.

Outer ventilation hood

Outer air duct

Inner air duct

Ceramic regenerator

Distance ring

Filter

Filter

Air flow rectifier

Ventilation unit

Decorative flat front panel

Fig. 1. Unit design

The unit has four ventilation modes:

1. Ventilation mode (air supply or air extract) at first speed.

2. Ventilation mode (air supply or air extract) at second speed.

3. Reversible mode (regeneration) at first speed.

4. Reversible mode (regeneration) at second speed.

In

regeneration mode

the unit operates in 2 cycles, 70 seconds each.

Cycle I.

Warm stale air is extracted from the premise, flows through the

ceramic regenerator and transfers its heat energy. In 70 seconds the

ceramic regenerator gets warmed up and the unit is switched to the

supply mode.

Cycle II.

Clean cold intake air flows through the regenerator, absorbs

humidity and is warmed up with the accumulated heat. In 70 seconds

the ceramic regenerator is cooled down and the unit is switched to the

extract air mode. The cycle begins anew.

CYCLE I

CYCLE II

-10 °С

-10 °С

+20 °С

+20 °С

+17 °С

+17 °С

-7 °С

-7 °С

70

se

c.

7

0 s

ec

.

A

IR E

XT

RA

CT

AI

R S

UP

PL

Y