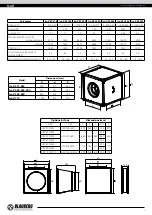

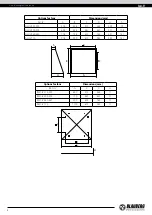

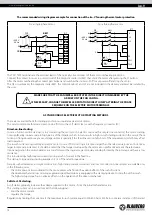

The recommended wiring diagram example for connection of the Iso-V fan using thermal motor protection

For a single-phase motor

For a three-phase motor

L

N

X1

1

2

3

N

L

QF

PE

~230 V

Hz

50

4

1

2

5

6

3

4

1

2

5

6

7

3

4

РЕ

L

N

X1

N

L

QF

PE

~230 V

Hz

50

TW1

TW2

TW1

TW2

TW1

TW2

TW1

TW2

TW1

TW2

TW1

TW2

W2

W1

V2

TW1

TW2

РЕ

L

N

X1

N

L

QF

PE

~230 V

Hz

50

РЕ

Х

2

NC

COM

Х

1

1

2

3

4

PE

L1

L2

L3

5

1

2

3

4

5

6

NC

COM

QF

L1

L2

L3

PE

~380 V

Hz

50

L2

L1

QF

PE

~400V

Hz

50

L2

L1

X1

2

7

1

3

L3

L3

5

4

6

V1

U1

PE

U2

TW1

TW2

W2

W1

V2

V1

U1

PE

U2

L1

L2

L3

8

9

РЕ

L2

L1

QF

PE

~400 V

Hz

50

L2

L1

X1

2

7

1

3

2

1

3

2

1

3

L3

L3

5

4

6

L1

L2

L3

8

9

TW2

TW1

TW1

TW2

PE

L

QF

~230 V

Hz

50

N

L

X1

PE

N

PE

+10V

0-10V

GND

+10V

CTR

GND

+10V

CTR

GND

+10V

CTR

GND

X2

QF PE

N

L

Х

1

~230 V

Hz

50/60

1

2

3

4

5

PE

N

L

Х

2

1

2

3

4

5

0-10V

RSB

RSA

GND

+10V

0-10V

RSB

RSA

GND

+10V

KL1

PE

L3

~400 V

50 Hz

QF

KL3

+20 V

0-10 V

RSA

RSB

RSA

RSB

GND

4-20 mA

+10 V

0-10 V

GND

OUT

KL2

NO

COM

NC

L1

L2

L2

L1

L3

PE

Подключение

аналогового

выхода

0-10 V

прибора

управления

0-10 V

GND

KL3

Подключение

релейного

выхода

прибора

управления

0-10 V

+10 V

KL3

KL3

Подключение

регулятора

(

потенциометра

)

0-10 V GND

+10 V

Подключение

датчика

критического

давления

4-20 mA

4-20 mA +20 V

KL3

Схема

внешних

подключений

и

универсального

соединения

вентиляторов

с

ЕС

-

двигателями

в

группу

L

N

X1

X1

1

2

3

L

QF

N

PE

TW1

4

5

6

TW2

~230 V

Hz

50

KM1

S1

“ON”

S2

“OFF”

KM1

РЕ

L1

TW1

TW2

S1

“ON”

S2

“OFF”

KM1

L2

L3

QF

~400 V

Hz

50

L1

L2

L3

N

PE

PE

L

N

X1

1

2

3

N

L

QF

PE

~230 V

Hz

50

4

1

2

5

6

3

4

1

2

5

6

7

3

4

РЕ

L

N

X1

N

L

QF

PE

~230 V

Hz

50

TW1

TW2

TW1

TW2

TW1

TW2

TW1

TW2

TW1

TW2

TW1

TW2

W2

W1

V2

TW1

TW2

РЕ

L

N

X1

N

L

QF

PE

~230 V

Hz

50

РЕ

Х

2

NC

COM

Х

1

1

2

3

4

PE

L1

L2

L3

5

1

2

3

4

5

6

NC

COM

QF

L1

L2

L3

PE

~380 V

Hz

50

L2

L1

QF

PE

~400V

Hz

50

L2

L1

X1

2

7

1

3

L3

L3

5

4

6

V1

U1

PE

U2

TW1

TW2

W2

W1

V2

V1

U1

PE

U2

L1

L2

L3

8

9

РЕ

L2

L1

QF

PE

~400 V

Hz

50

L2

L1

X1

2

7

1

3

2

1

3

2

1

3

L3

L3

5

4

6

L1

L2

L3

8

9

TW2

TW1

TW1

TW2

PE

L

QF

~230 V

Hz

50

N

L

X1

PE

N

PE

+10V

0-10V

GND

+10V

CTR

GND

+10V

CTR

GND

+10V

CTR

GND

X2

QF PE

N

L

Х

1

~230 V

Hz

50/60

1

2

3

4

5

PE

N

L

Х

2

1

2

3

4

5

0-10V

RSB

RSA

GND

+10V

0-10V

RSB

RSA

GND

+10V

KL1

PE

L3

~400 V

50 Hz

QF

KL3

+20 V

0-10 V

RSA

RSB

RSA

RSB

GND

4-20 mA

+10 V

0-10 V

GND

OUT

KL2

NO

COM

NC

L1

L2

L2

L1

L3

PE

Подключение

аналогового

выхода

0-10 V

прибора

управления

0-10 V

GND

KL3

Подключение

релейного

выхода

прибора

управления

0-10 V

+10 V

KL3

KL3

Подключение

регулятора

(

потенциометра

)

0-10 V GND

+10 V

Подключение

датчика

критического

давления

4-20 mA

4-20 mA +20 V

KL3

Схема

внешних

подключений

и

универсального

соединения

вентиляторов

с

ЕС

-

двигателями

в

группу

L

N

X1

X1

1

2

3

L

QF

N

PE

TW1

4

5

6

TW2

~230 V

Hz

50

KM1

S1

“ON”

S2

“OFF”

KM1

РЕ

L1

TW1

TW2

S1

“ON”

S2

“OFF”

KM1

L2

L3

QF

~400 V

Hz

50

L1

L2

L3

N

PE

PE

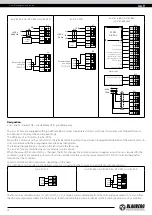

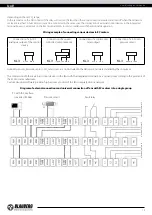

The TW1, TW2 terminals are the electrical leads of the normally closed contact of the motor overheating protection.

Connect the contact in series to power circuit of the magnetic starter coil KM1 that starts the motor after pressing the S1 button.

After the motor overheating the contact gets broken and switches the starter coil off to cut power off and stop the motor.

The QF circuit breaker, the magnetic starter KM1, the control knobs S1 and S2 are not included in the delivery and must be installed by

the user.

ASYNCHRONOUS ELECTRIC MOTOR STARTING METHODS

There are several methods for starting asynchronous squirrel-cage electric motors.

The most common methods are: direct-on-line (DOL), with a soft starter (SS) or with a frequency converter (FC).

Direct-on-line starting

In case of direct-on-line starting (i.e. by connecting the motor to the electric mains with a simple line contactor), the motor starting

time significantly increases due to high inertia of the impeller, which, in turn, results in high in-rush starting currents in the circuit. These

currents of long duration may cause voltage slumps (especially if the feed line section falls short of the requirements), which may affect

load operation.

The in-rush current consumed by an electric motor in case of DOL starting is 5-8 times larger than the rated value (or even 10-14 times

larger in some rare instances). It should be noted that the torque developed by the motor also significantly exceeds the rated value.

Upon energisation the motor operates as a transformer with a squirrel-cage secondary winding formed by the rotor cage with a very low

resistance.

The rotor develops high induced current causing a rush of current in the feed line.

The startup torque during starting averages 0.5-1.5 of the rated torque value.

Despite such advantages as simple construction, high startup current, quick start and low cost, direct-on-line systems are suitable only

in the following cases:

• the motor power is low compared to the mains power which limits the adverse effect of the rush of current

• the driven mechanism does not require gradual speed build-up or is equipped with a damping device to smooth out the inrush

• the high startup torque has no adverse effects on the operation of the driven mechanism

Soft start. SS starting.

A soft starter gradually increases the voltage supplied to the motor – from the initial to the rated value.

This starting system can be used to meet the following goals:

• limit the motor current

• regulate the torque

Regulation by limiting the current sets the maximum in-rush current equal to 300-400 % (or 250 % in some rare instances) of the rated

MAKE SURE THAT THE FAN IMPELLER ROTATES IN THE DIRECTION MARKED BY THE

ARROW ON THE FAN CASING.

IF NECESSARY, CHANGE THE IMPELLER ROTATION DIRECTION BY ALTERING THE PHASE

SEQUENCE ON THE ELECTRIC MOTOR TERMINALS.

www.blaubergventilatoren.de

iso-V

14