REV E

5-6

108936BD_0812

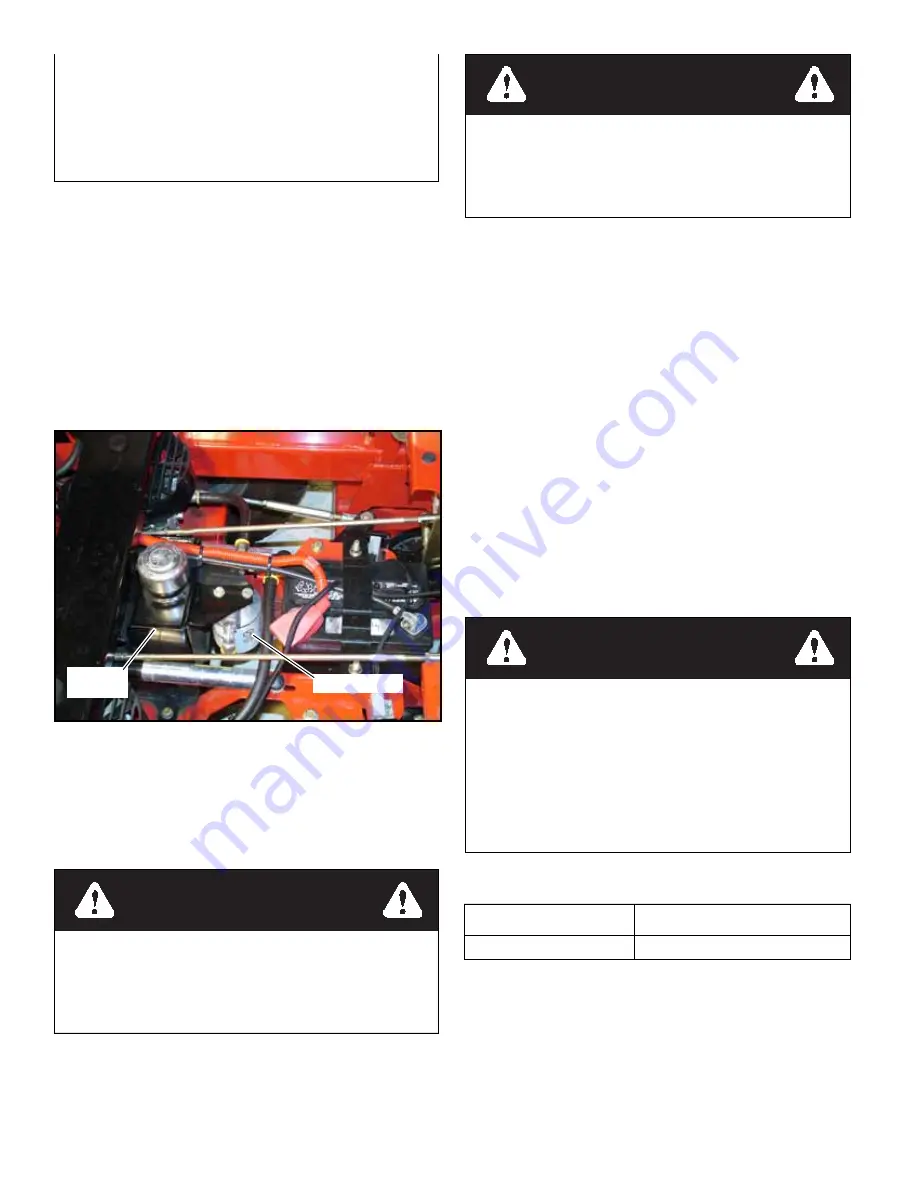

Check oil level in hydraulic system after every 50 hours of

operation or weekly, whichever occurs first. Check more often if

system appears to be leaking or otherwise malfunctioning.

Fluid level should be 1” (2.54cm) from top of reservoir. Use

only SAE 20W50 SL/SM service motor oil. Figure 5-15

Change hydraulic system filter element and oil after first 50

hours of machine operation, then replace filter and oil in reser-

voir every 500 hours thereafter. Figure 5-15

The system filter is located in front of the hydraulic reservoir.

A standard oil filter wrench is used to change filter, threads are

right handed.

Use a BigDog

®

Mowers approved filter element

only.

Prefill the filter element with clean oil, before installing,

to prevent drawing air into the system pump.

Hydraulic Pump Flow Test

The design purpose of the Bi-Directional Flow Test Kit is to

allow the customer to isolate the pump from the wheel motor

and determine if the pump is acceptable. The following informa-

tion can be used to install and test the pump by simulating a

wheel motor load.

Installation & Testing Procedures

Disconnect the system hoses at the wheel motor, or system

hoses from the pump and connect the Bi-Directional Flow Test

Kit. (Special care should be taken to prevent contamination

debris from entering pump or wheel motor system ports).

NOTE:

Using the Bi-Directional Flow Test Kit, determina-

tion of directional flow is not necessary. The flow meter may be

connected in either direction into the forward and reverse high

pressure system lines.

NOTE:

The following adapter fittings will be required when

connecting the Bi-Directional Test Kit (Excel P/N 783886 or

Hydro-Gear P/N 70661):

PK (12) Series Pumps require two 771311 adapter

fittings.

CAUTION:

Ensure all fittings and hoses are attached

securely. This test is being completed on the vehicle’s high pres-

sure system lines. Failure to perform this properly could result

in bodily injury.

Testing Procedures

1.

Use approved jack stands to raise the drive wheels off the

floor.

2.

Open the restriction valve all the way.

3.

Bring the engine to maximum operating speed.

CAUTION:

Damage to the flow meter and/or re-calibration

may result from testing at input speeds that exceed the above

recommendations.

4.

For the pump being tested, move the steering control

levers in full forward motion. (It will be necessary to lock

the steering control levers into full forward position to

prevent false readings).

5.

Operate without any load for approximately 30 seconds

to 1 minute. This allows the system oil temperature to

Before applying pressure to hydraulic system, make sure

all connections are tight and all hoses and lines are in

good condition. To find a leak under pressure, use a piece

of cardboard or wood —

never

use your hands. Relieve

all pressure in the system before disconnecting or work-

ing on hydraulic lines. To relieve pressure, lower all

attachments and shut off engine.

Figure 5-15

WARNING

Certain procedures require the vehicle engine to be

operated and the vehicle to be raised off of the ground.

To prevent possible injury to the servicing technician

and/or bystanders, insure the vehicle is properly

secured.

Hydraulic filter

Hydraulic

reservoir

WARNING

Do not attempt any adjustments with the engine run-

ning. Use extreme caution while working in or around

all vehicle linkage! High temperatures can be gener-

ated. Follow all safety procedures outlined in the vehi-

cle owner’s manual!

WARNING

Never work under the machine or attachment unless it is

safely supported with jack stands. Make certain machine

is secure when it is raised and placed on the jack stands.

The jack stands should not allow the machine to move

when the engine is running and the drive wheels are rotat-

ing. Use only certified jack stands. Use only appropriate

jack stands, with a minimum weight rating of 2000

pounds to block the unit up. Use in pairs only. Follow the

instructions supplied with the vehicle stands.

Pumps

Engine full throttle rpm setting

PK (12)

3600

Содержание Series X

Страница 4: ...c 2 108936BD_ 0812 Troubleshooting 10 1...

Страница 6: ...REV E 2 2 108936BD_0812...

Страница 10: ...REV E 3 4 108936BD_0812...

Страница 12: ...REV E 4 2 108936BD_0812...

Страница 30: ...REV E 7 6 108936BD_0812...

Страница 31: ...108936BD_0812 8 1 REV E ELECTRICAL Electrical Schematic Briggs Stratton...

Страница 32: ...REV E 8 2 108936BD_0812 Electrical Schematic Kawasaki...

Страница 33: ...108936BD_0812 8 3 REV E Electrical Schematic Kohler...

Страница 34: ...REV E 8 4 108936BD_0812...

Страница 38: ...REV E 9 4 108936BD_0812...