HLDA

– Double acting - Doubled thrust hydraulic linear actuator

Use and maintenance manual

© Copyright by BIFFI Italia. All right reserved.

Pag. 12

Contents may change without notice

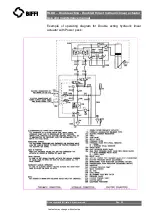

1) Check that the coupling dimensions of the valve flange and stem,

or of the relevant extension, meet the actuator coupling

dimensions (valve stem and flange). Lubricate the valve stem with

grease in order to make the assembly easier.

2)

Connect a sling to the support point of the actuator and lift it.

To make easier the assembly , the valve stem has to be in perfect

vertical

position.

Note

:

the eyebolt is sized for the lifting of the only actuator (NOT

AVALVE). Proper lifting points have to be foreseen for

the valve.

3) . Screw the actuator coupling joint onto the valve by rotating the

actuator, or screw down the valve stem stroke-ring with Red

Loctite 542 and fix the half-bearings. When the threaded holes of

the actuator flange are in correspondence with the holes on the

valve flange screw the proper stud bolts. Screw the nuts on the

stud bolts and tighten up the valve flange is in contact with the

actuator flange.

4) Tighten the nuts of the connecting stud bolts evenly with the

torque prescribed in the table. The stud bolts must be made of

ASTM A320 L7 steel, the nuts must be made of ASTM A194 grade

2 steel as minimum.